Crosslinking method of agarose 4B microspheres

A cross-linking method and agarose technology, applied in the cross-linking field of agarose 4B microspheres, can solve the problems of inability to meet industrial pressure and flow rate, poor mechanical strength, and high water content, and achieve easy control and amplification, and less environmental pollution. , the effect of high degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

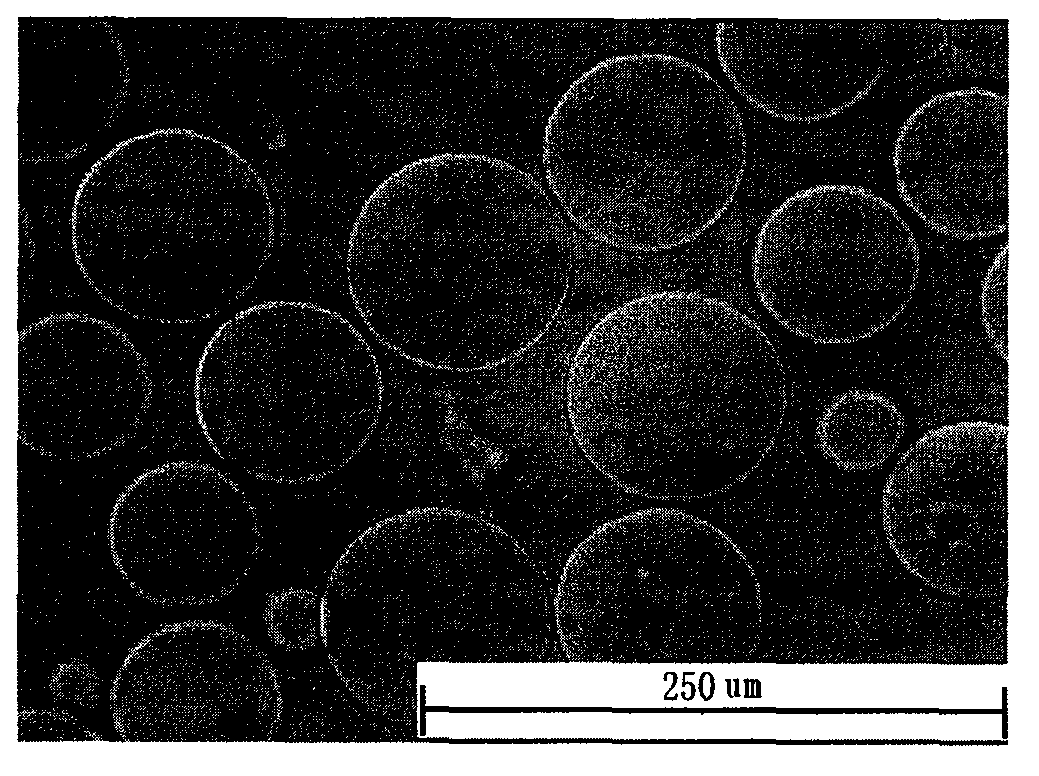

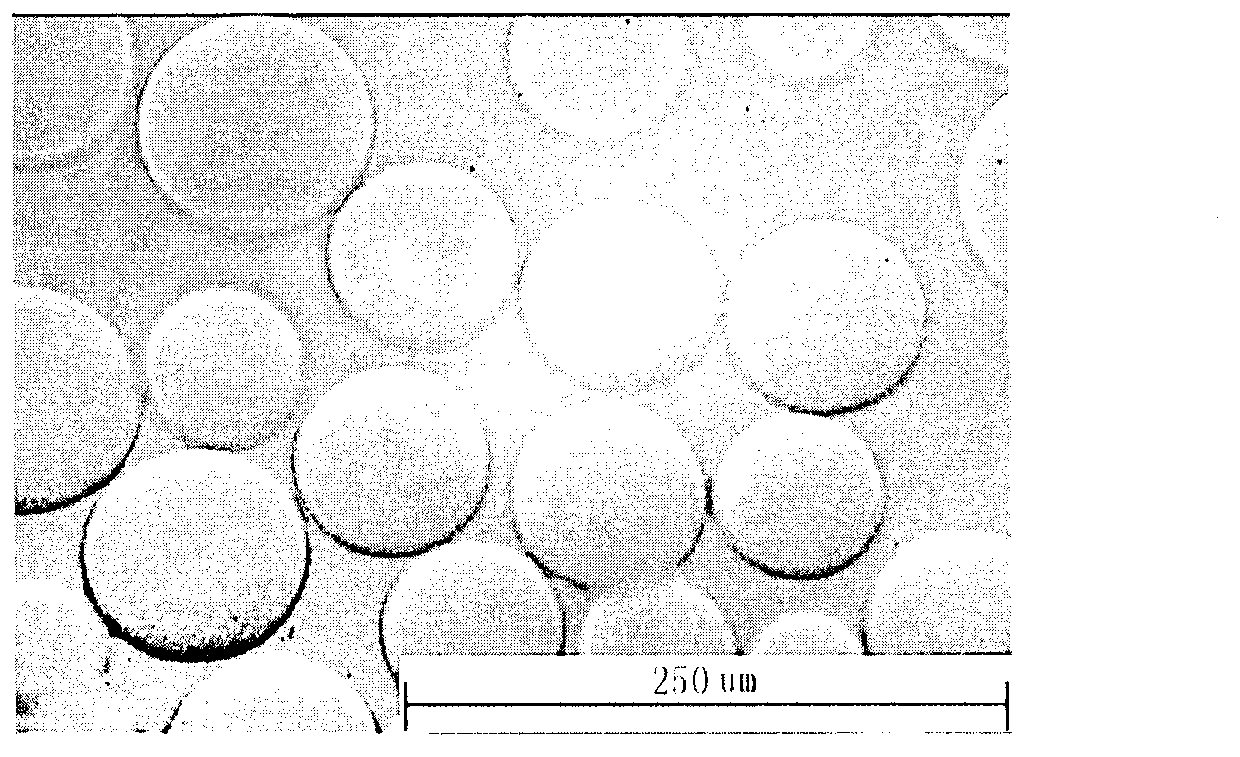

Image

Examples

Embodiment 1

[0019] Take 40g of Sepharose 4B microspheres in a 500mL Erlenmeyer flask with a stopper, add 60mL of 1.0mol / L NaOH solution, let it stand at 30°C for 10min, then add 32mL of dimethyl sulfoxide, 6mL of absolute ethanol and 10mL of pentaerythritol glycidol in sequence Ether was reacted in a water-bath shaker at 30° C. and 170 rpm for 6 h, and washed with 20% ethanol, acetone, and deionized water in sequence.

[0020] Take 40g of cross-linked microspheres in a 500mL Erlenmeyer flask with a stopper, add 60mL, 3.0mol / L NaOH solution, let stand at 30°C for 10min, then add 32mL dimethyl sulfoxide and 10mL epichlorohydrin in turn, put in In a water-bath shaker at 170 rpm, wash with 20% ethanol, acetone, and deionized water at 30° C., 35° C., and 40° C. for 2 hours respectively. After high temperature sterilization, the loss rate is about 1.5%.

[0021] The agarose 4B microspheres after the secondary cross-linking were packed into a column (column inner diameter 1cm, column height 3cm...

Embodiment 2

[0023] Take 40g of Sepharose 4B microspheres in a 500mL Erlenmeyer flask with a stopper, add 60mL of 1.0mol / L NaOH solution, let it stand at 30°C for 10min, then add 34mL of dimethyl sulfoxide, 6mL of absolute ethanol and 8mL of pentaerythritol glycidol in sequence Ether was reacted at 30° C. in a water-bath shaker at 170 rpm for 6 h, and washed with 20% ethanol, acetone, and deionized water in sequence.

[0024] Take 40 g of cross-linked microspheres into a 500 mL Erlenmeyer flask with a stopper, add 60 mL of 3.0 mol / L NaOH solution, let it stand at 30°C for 10 min, then add 34 mL of dimethyl sulfoxide and 8 mL of epichlorohydrin in sequence, and place in In a water-bath shaker at 170 rpm, wash with 20% ethanol, acetone, and deionized water at 30° C., 35° C., and 40° C. for 2 hours respectively. After high temperature sterilization, the loss rate is about 1.6%. The agarose 4B microspheres after the secondary cross-linking were packed into a column (column inner diameter 1cm,...

Embodiment 3

[0026] Take 40g of Sepharose 4B microspheres in a 500mL Erlenmeyer flask with a stopper, add 50mL of 1.0mol / L NaOH solution, let it stand at 30°C for 10min, then add 32mL of dimethyl sulfoxide, 6mL of absolute ethanol and 15mL of pentaerythritol glycidol Ether was reacted at 30° C. in a water-bath shaker at 170 rpm for 5 h, and washed with 20% ethanol, acetone, and deionized water in sequence.

[0027] Take 40 g of once cross-linked microspheres into a 500 mL Erlenmeyer flask with a stopper, add 50 mL of 3.0 mol / L NaOH solution, let it stand at 30°C for 10 min, then add 32 mL of dimethyl sulfoxide and 15 mL of epichlorohydrin in sequence, and place in In a water-bath shaker at 170 rpm, wash with 20% ethanol, acetone, and deionized water at 30° C., 35° C., and 40° C. for 2 hours respectively. After high temperature sterilization, the loss rate is about 1.8%.

[0028] The agarose 4B microspheres after the secondary cross-linking were packed into a column (column inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com