Preparation method of crude oil rapid demulsifying agent

A demulsifier and rapid technology, applied in the field of preparation of crude oil rapid demulsifier, can solve the problems of large dosage, slow demulsification speed, and high demulsification temperature, and achieve the effects of being beneficial to environmental protection and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

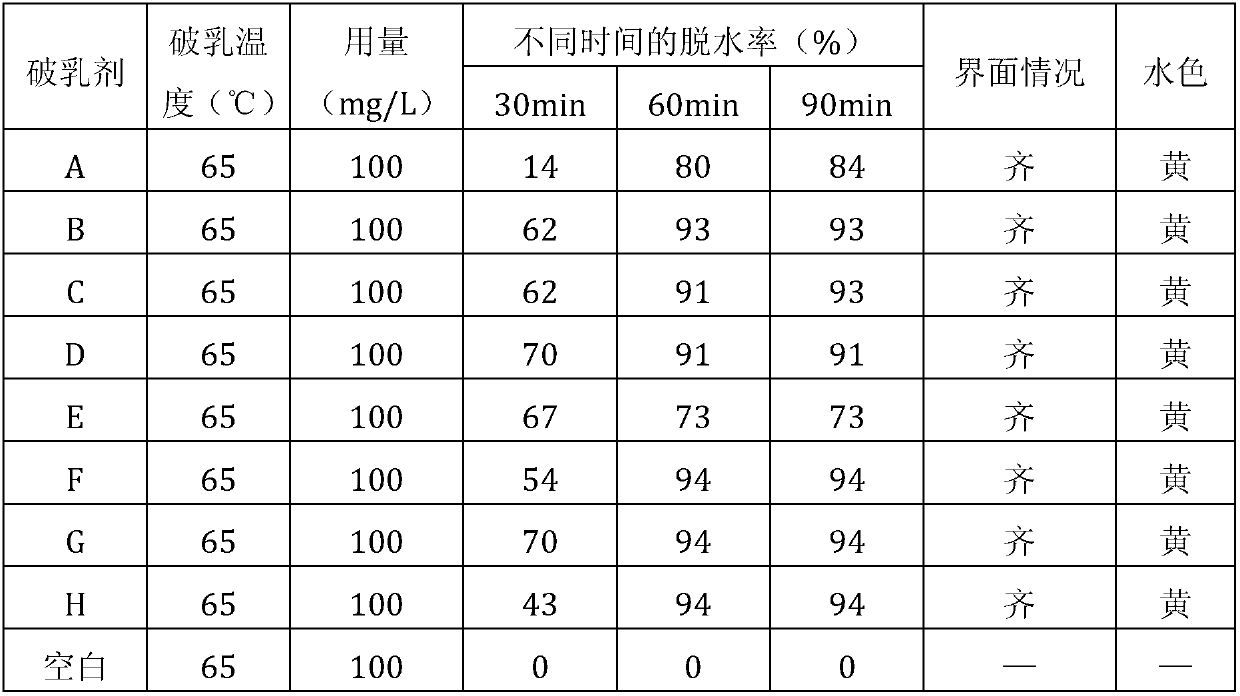

Examples

Embodiment 1

[0027] Embodiment 1. Synthesis of polyether demulsifier A

[0028] (1) Synthesis of initiator phenolamine resin

[0029] Add 25g of bisphenol A and 82.5g of tetraethylenepentamine into a 500ml three-necked bottle, stir and raise the temperature to dissolve the bisphenol A. After the bisphenol A is completely dissolved, cool to 35°C, and dropwise add 37.5g with a mass fraction of 36%. formaldehyde solution, keep the temperature at 30-40°C, and keep it warm for 40 minutes after the dropwise addition is completed. Add 72.5g of xylene and raise the temperature to 100-110°C. Reflux reaction 2h. Slowly raise the temperature and take out the water under the condition of reflux. After all the water is evaporated, then evaporate the xylene to obtain the initiator phenolamine resin.

[0030] (2) Synthesis of polyether demulsifier A

[0031] Add 1g of the starter phenolamine resin and 1g of potassium hydroxide obtained in step (1) into the autoclave, seal the autoclave, start stirrin...

Embodiment 2

[0033] Embodiment 2. Synthesis of cross-linked demulsifier B

[0034] Add 10 g of the polyether demulsifier A prepared in Example 1 into a 25 ml single-necked bottle, and heat up to about 100° C. for vacuum dehydration. After the dehydration is completed, add 0.5 g of methyl ethoxy silicone oil and 0.07 g of oleic acid, and react under reduced pressure for 30 minutes. The reaction is terminated when the material becomes thick and silky. The reaction result is cross-linked demulsifier B.

Embodiment 3

[0035] Embodiment 3. Synthesis of cross-linked demulsifier C

[0036] As described in Example 2, the difference is that the feeding amount of methyl ethoxy silicone oil is changed to 1 g, the feeding amount of oleic acid is changed to 0.13 g, and the reaction result is cross-linked demulsifier C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com