Thermal stability improved polyformaldehyde resin composition and preparation method thereof

A polyoxymethylene resin, thermal stability technology, applied in the field of resin composition and its preparation, can solve the problems of insufficient notched impact strength, polyoxymethylene is easy to oxidize and discolor at high temperature, and polyoxymethylene mold scale is less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh the following materials by weight percentage:

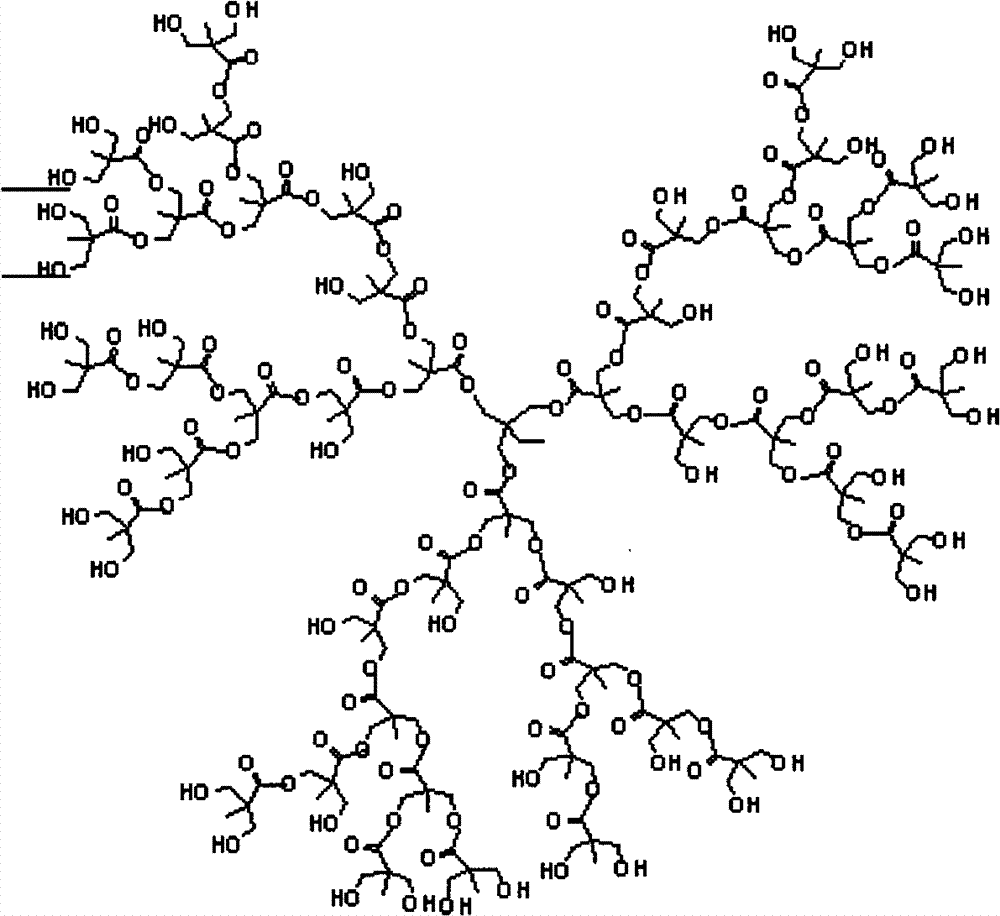

[0043] Polyoxymethylene resin 96%, hyperbranched polyester (see structural formula 1, the bonding group is an ester group, the terminal group is a hydroxyl group, and the number average molecular weight is 5000-6000) 0.6%, N, N'-bis-[3-( 3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine 0.2%, tris(2.4-di-tert-butylphenyl)phosphite 0.1%, magnesium oxide 0.1%, stearin Calcium Acid 3%.

[0044] Dry the polyoxymethylene resin at 80°C for 3 hours, then put it into a high-speed mixer and mix it with the above-mentioned other materials, use a vented co-rotating twin-screw extruder to melt and blend, extrude and granulate, and the screw speed is 280 rpm Minutes, barrel temperature (temperature) is:

[0045] Hopper Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Zone 8, Zone 9

[0046] Room temperature 165 170 175 180 185 185 190 190 190 185

Embodiment 2

[0048] Weigh the following materials by weight percentage:

[0049] Polyoxymethylene resin 91.8%, hyperbranched polyester (see structural formula 1, the bonding group is an ester group, the terminal group is a hydroxyl group, and the number average molecular weight is 9000-10000) 2%, tetrakis [β-(3,5-ditertiary Butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.6%, tris(2.4-di-tert-butylphenyl)phosphite 0.3%, magnesium oxide 0.3%, calcium stearate 5%.

[0050] Dry the polyoxymethylene resin at 80°C for 3 hours, then put it into a high-speed mixer and mix it with the above-mentioned other materials, use a vented co-rotating twin-screw extruder to melt and blend, extrude and granulate, and the screw speed is 210 rpm minute, the barrel temperature (°C) is:

[0051] Hopper Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 Machine head

[0052] Room temperature 160 165 170 170 175 175 180 180 180 175

Embodiment 3

[0054]Weigh the following materials by weight percentage:

[0055] Polyoxymethylene resin 94.2%, hyperbranched polyester (see structural formula 1, the bonding group is an ester group, the terminal group is a hydroxyl group, and the number average molecular weight is 7000-8000) 1%, β-(3,5-di-tert-butyl 0.4% stearyl-4-hydroxyphenyl) propionate, 0.2% tris(2.4-di-tert-butylphenyl) phosphite, 0.2% magnesium hydroxide, 4% magnesium stearate.

[0056] Dry the polyoxymethylene resin at 80°C for 3 hours, then add the above-mentioned other materials into a high-speed mixer and mix them, use a vented co-rotating twin-screw extruder to melt and blend, extrude and granulate, and the screw speed is 250 rpm minute, the barrel temperature (°C) is:

[0057] Hopper Zone 1, Zone 2, Zone 3, Zone 4, Zone 5, Zone 6, Zone 7, Zone 8, Zone 9

[0058] Room temperature 160 170 170 175 180 180 185 185 185 180

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com