Preparation method of magnetic sepharose gel microspheres

A technology of agarose gel and microspheres, which is applied in the preparation of microspheres, the magnetism of organic materials/organic magnetic materials, microcapsule preparations, etc. It can solve the problems of unsatisfactory magnetic responsiveness, achieve good application prospects, and save raw materials , Strong magnetic response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

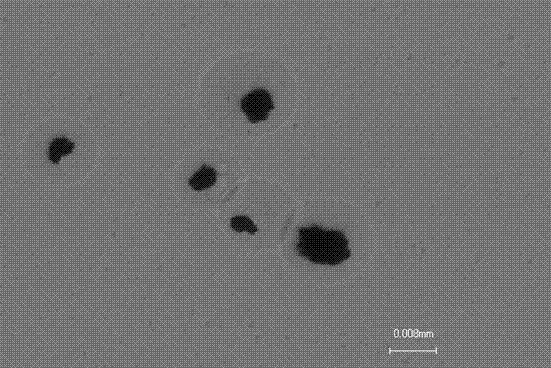

Image

Examples

Embodiment 1

[0023] Preparation of active agent-dispersed iron powder: Accurately weigh 0.015mol sodium citrate (4.41g) in 30ml distilled water to make a solution with a concentration of 0.5M, add 0.01mol iron powder (0.56g) to it, and the average iron powder The particle size is 40nm; heat in a water bath at 80°C and stir vigorously for 2 hours, and the stirring speed is 500rpm / min. The magnetic particles were collected by a magnet, washed five times with distilled water and ethanol, and dried in vacuum at 60°C for 6 hours.

[0024] Preparation of magnetic agarose gel microspheres: Dissolve 3.6g span80 in 90mL liquid paraffin, preheat to 70°C in a 250mL capacity three-neck flask; accurately weigh 0.45g agarose and 45mg active agent dispersed iron powder, add 90mL double-distilled water to make 0.5% agarose solution, repeat ultrasonication and microwave heating to dissolve; transfer the water phase to the oil phase, and mechanically stir at 80°C for 0.5h at a stirring speed of 500rpm / min. ...

Embodiment 2

[0026] Preparation of active agent-dispersed iron powder: Accurately weigh 0.07mol sodium citrate (20.59g) in 260ml distilled water to make a solution with a concentration of 0.27M, add 0.01mol iron powder (0.56g) to it, and the average iron powder The particle size is 50nm; heated in a water bath at 70°C and stirred vigorously for 4 hours, and the stirring speed is 1500rpm / min. The magnetic particles were collected by a magnet, washed five times with distilled water and ethanol, and dried in vacuum at 80°C for 6 hours.

[0027] Preparation of magnetic agarose gel microspheres: Dissolve 3.6g span80 in 337.5mL liquid paraffin, preheat to 80°C in a 2000mL capacity three-necked flask; accurately weigh 0.9g agarose and 180mg active agent dispersed Iron powder, add 22.5mL double-distilled water to make a 4% agarose solution, repeat ultrasonication and microwave heating to dissolve; transfer the water phase to the organic phase, and mechanically stir at 80°C for 1h at a stirring spe...

Embodiment 3

[0030] Preparation of active agent dispersed iron powder: Accurately weigh 0.03mol sodium lauryl sulfate (8.64g) in 120ml distilled water to make a solution with a concentration of 0.25M, add 0.01mol iron powder (0.56g) to it, The average particle size of the iron powder is 2 μm; it is heated in a water bath at 90°C and stirred vigorously for 1 hour, and the stirring speed is 2000 rpm / min. The magnetic particles were collected by a magnet, washed five times with distilled water and ethanol, and dried in vacuum at 40°C for 12 hours.

[0031] Preparation of magnetic agarose gel microspheres: Dissolve 2g span80 in 625mL liquid paraffin, preheat to 80°C in a 1000mL capacity three-neck flask; accurately weigh 1g agarose and 0.5g active agent dispersed iron powder , add 12.5mL double distilled water to make 8% agarose solution, repeat ultrasonication and microwave heating to dissolve; transfer the aqueous phase to the organic phase, and mechanically stir at 90°C for 1h at a stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com