Photocatalyst as well as preparation method and application method thereof

A photocatalyst and nanofiber technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of easy recombination of photogenerated electrons and holes, insufficient specific surface area, etc. Separation, improving optoelectronic properties, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, CdS-ZnS / TiO of the present invention 2 Preparation of nanofibers

[0028] (1) Under magnetic stirring, add 1.5g tetraisopropyl titanate, 3mL ethanol and 3mL acetic acid to a 10mL beaker, stir magnetically for about 30min, then add PVP solution (0.45g PVP dissolved in 3mL ethanol), and continue stirring for 1h .Get TiO 2 Sol;

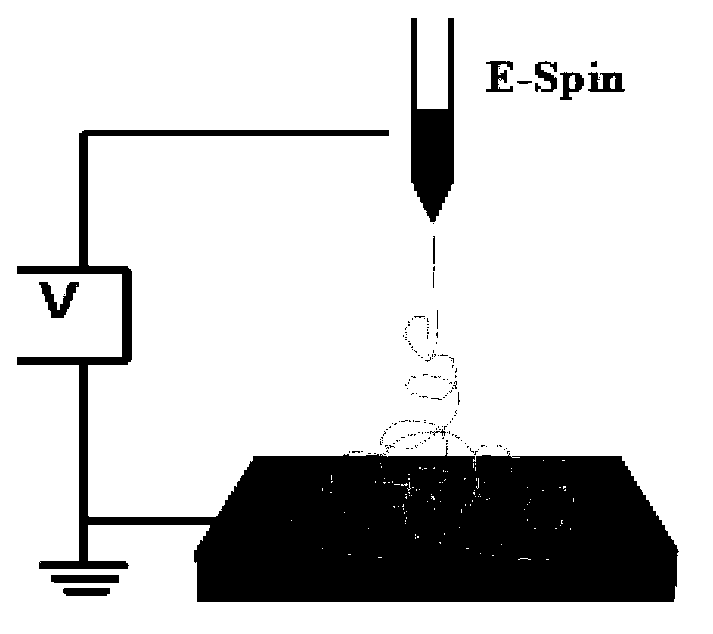

[0029] (2) Add the above sol into the syringe ( figure 1 ), the operating voltage is controlled to be 10kV, the distance between the receiver and the spinning needle is adjusted to be 10cm, and the outflow rate of the solution is 0.5mL / h. The solution in the tube is sprayed out stably, and the collecting plate is made of aluminum foil.

[0030] (3) The spun fibers were dried in a vacuum oven (120°C) for 12h, and then calcined at 450°C for 3h. Then naturally lowered to room temperature, TiO 2 Nanofibers.

[0031] (4) CdS-ZnS / TiO 2 Preparation of nanofibers

[0032] ① Put TiO 2 The nanofibers were impregnated with 0.2mol / L Zn(N...

Embodiment 2

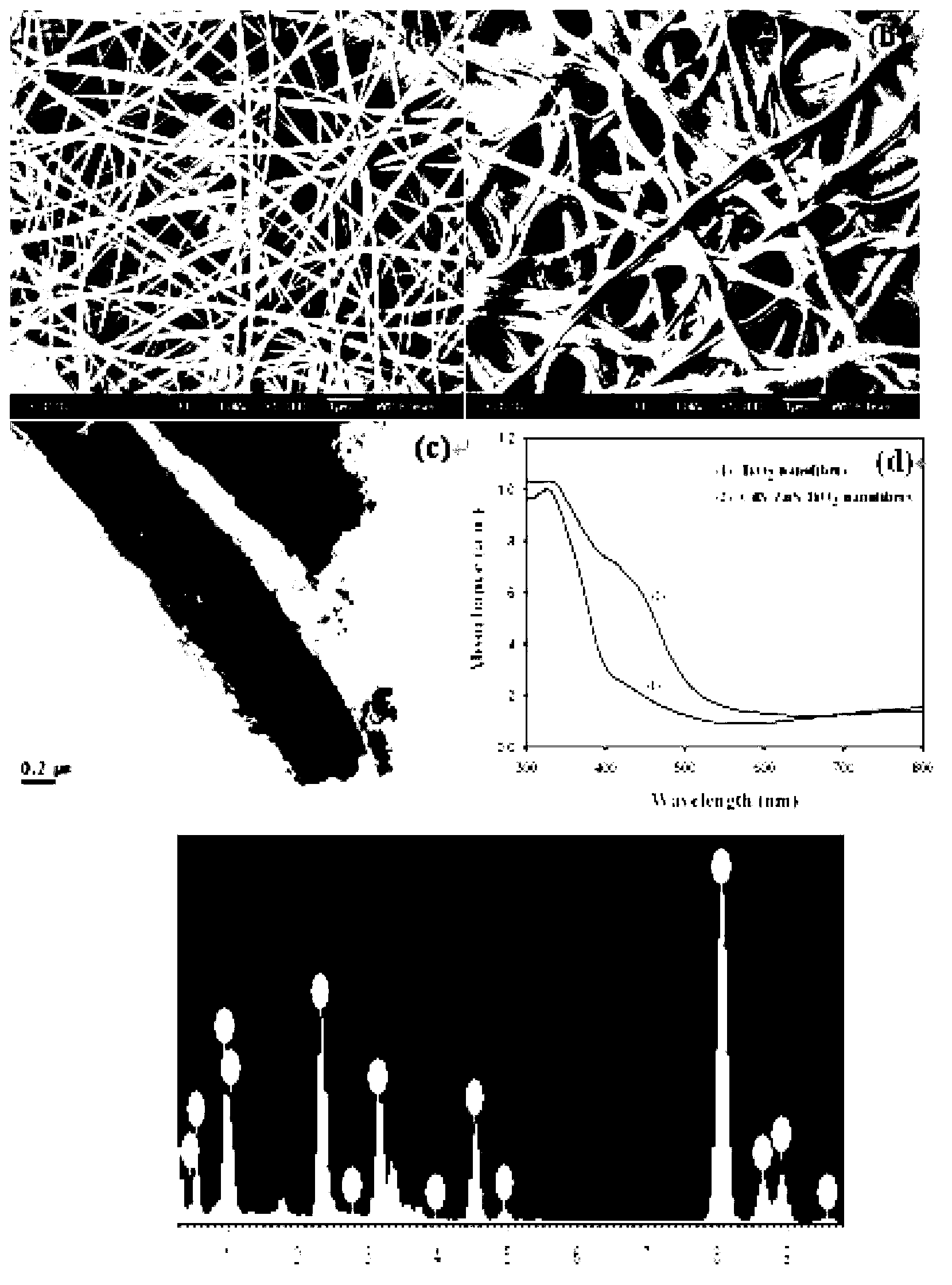

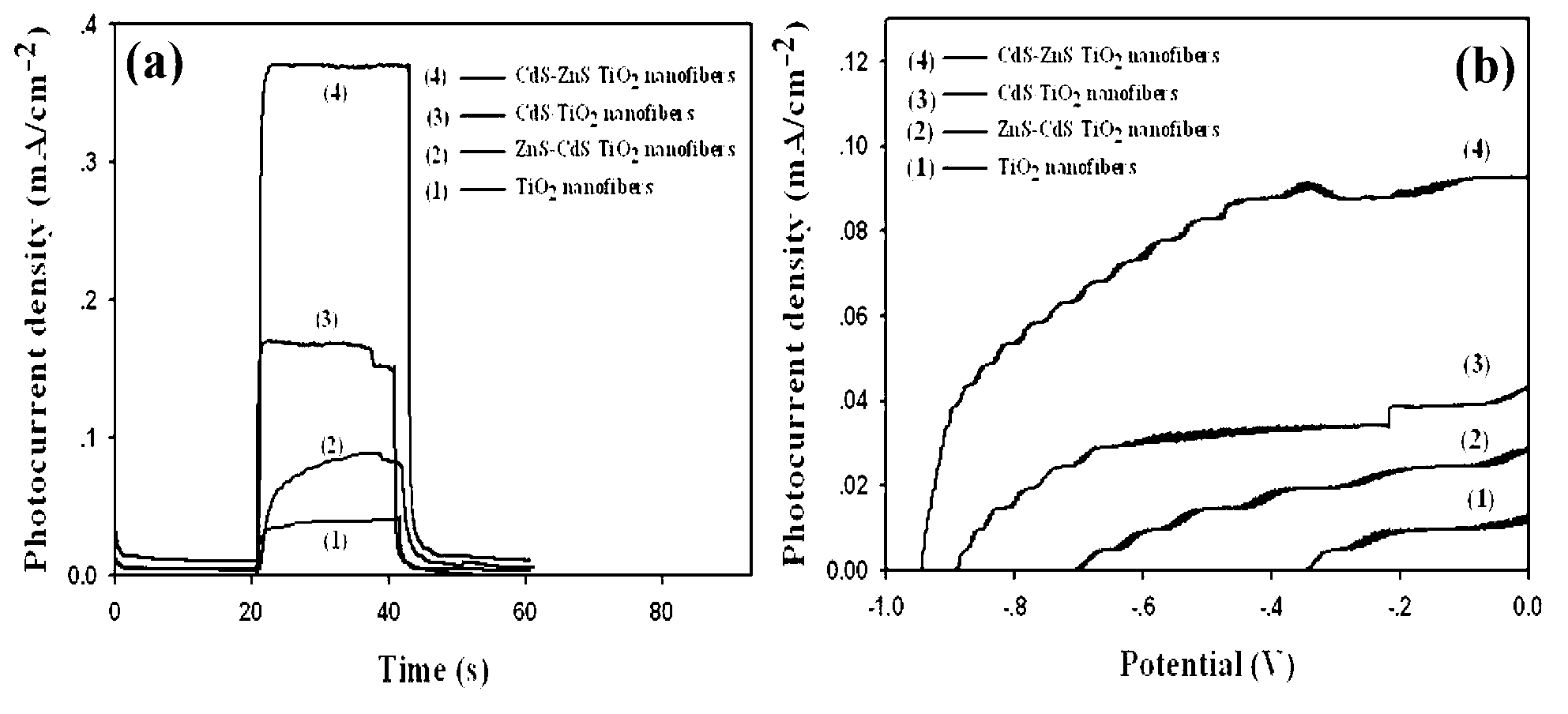

[0035] TiO 2 Nanofibers, CdS / TiO 2 Nanofiber, ZnS-CdS / TiO 2 Nanofiber, CdS-ZnS / TiO 2 Nanofibers were tested for optoelectronic properties.

[0036] Implementation steps:

[0037] (1) CdS-ZnS / TiO fixed on ITO glass 2 Nanofibers are placed in 50mL KOH solution with a concentration of 1mol / L;

[0038] (2) Use a Xe lamp with a light source of 500W (100mW / cm 2 ), photoelectrochemical tests were carried out on it under visible light;

[0039] (3) The photoelectrochemical performance test was carried out on a standard three-electrode system electrochemical workstation (CHI600D, Shanghai Chenhua), in which the Pt electrode was used as the counter electrode, the saturated calomel electrode (SCE) was used as the reference electrode, and the CdS-ZnS / TiO 2 Nanofibers are working electrodes. The electrolyte is 0.1mol / L KOH.

[0040] (4) Control experiment on TiO 2 Nanofibers, CdS / TiO 2 Nanofiber, ZnS-CdS / TiO 2 On the nanofiber, the steps are the same as above.

[0041] image...

Embodiment 3

[0044] CdS-ZnS / TiO 2 Nanofiber Photocatalytic Degradation of Methylene Blue

[0045] The present invention adopts CdS / TiO 2 Nanofibers, CdS-ZnS / TiO 2 Nanofibers degrade 5mg / L methylene blue wastewater respectively.

[0046] Implementation steps:

[0047] (1) CdS-ZnS / TiO fixed on ITO glass 2 Nanofibers (the size of ITO glass is 1cm×4cm, the effective area is 1cm×3cm, a total of 3 pieces) were put into 50mL of methylene blue wastewater with a concentration of 5mg / L;

[0048] (2) Use a Xe lamp with a light source of 500W (100mW / cm 2 ), photocatalytic degradation of it under visible light;

[0049] (3) After regular sampling, use a UV-Vis spectrophotometer to monitor the change of methylene blue in the solution;

[0050] (4) Control experiment in CdS / TiO 2 On the nanofiber, the steps are the same as above, and the cycle is 3 times.

[0051] Figure 4 is CdS / TiO 2 Nanofibers and CdS-ZnS / TiO 2 Experimental diagram of three cycles of degradation of methylene blue solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com