Method for preparing ATO-based PTC (positive temperature coefficient) material

A raw material, press-forming technology, applied in the field of preparation of ATO-based PTC materials, can solve problems such as hidden safety hazards, and achieve the effects of reduced energy consumption, less environmental disturbance, and reduced heat treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

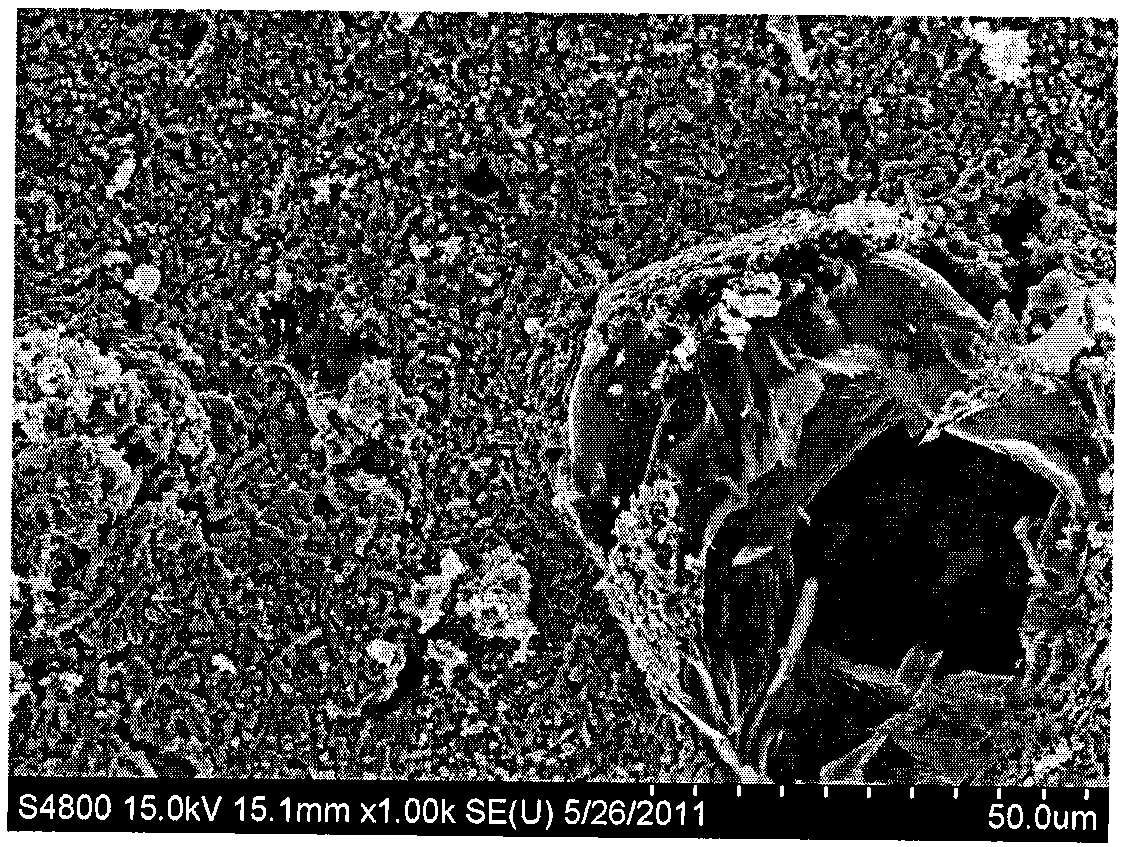

[0020] Using diammonium hydrogen phosphate and stannous oxide as raw materials, P 2 o 5 The molar ratio to Sn is 0.3, the raw materials are mixed evenly and then heat-treated at 900°C for 15 minutes, and then water quenched to pulverize the obtained glass slag to obtain PS glass powder. Take by weighing 1 gram of PS glass powder, 5 gram of stannous oxalate, 0.2 gram of stannous chloride, 0.5 gram of antimony trioxide, 0.1 gram of cerium dioxide, mix the above-mentioned raw materials, press molding, and then Heat treatment at 600 degrees for 2 hours to obtain product a, the scanning electron microscope photo of product a is shown in Figure 1a , powder X-ray diffraction pattern see Figure 2a , The resistance-temperature curve 3a of the product.

Embodiment 2

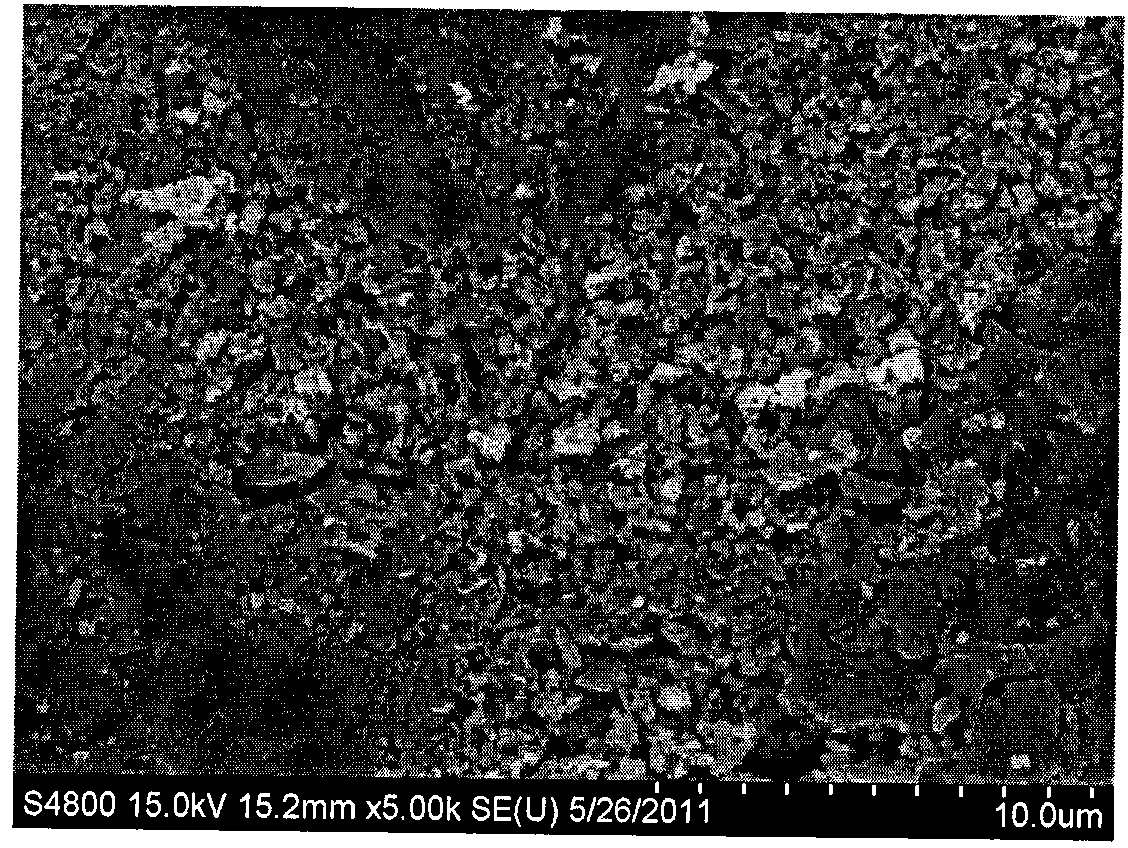

[0022] Using diammonium hydrogen phosphate and stannous chloride as raw materials, P 2 o 5 The molar ratio to Sn is 0.4, the raw materials are mixed uniformly and then heat-treated at 600°C for 15 minutes, and then water quenched to pulverize the obtained glass slag to obtain PS glass powder. Weigh 1.5 grams of PS glass powder, 5 grams of tin dioxide, 0.5 grams of antimony trioxide, and 0.3 grams of ceria, mix the above raw materials, press and shape, and then heat treat at 500 degrees for 2 hours to obtain the product b, the scanning electron micrograph of product b is shown in Figure 1b , powder X-ray diffraction pattern see Figure 2b , The resistance-temperature curve 3b of the product.

Embodiment 3

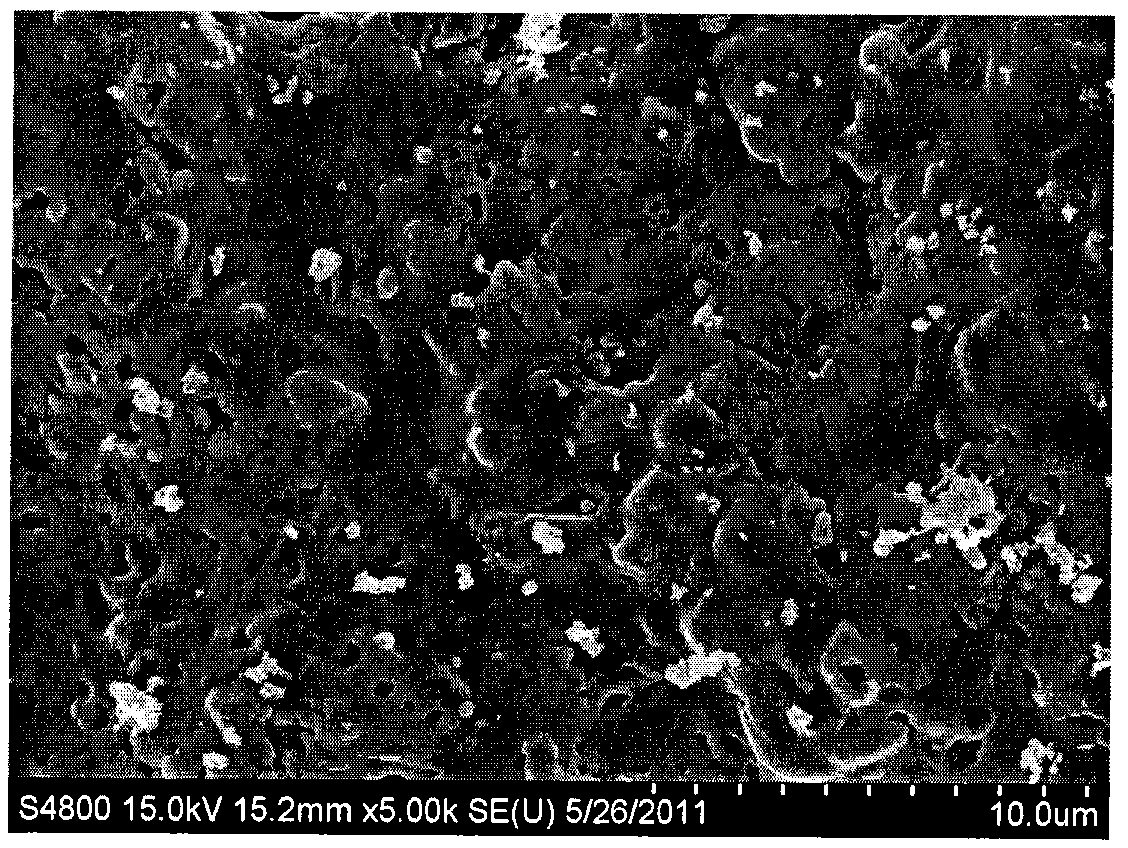

[0024] Using diammonium hydrogen phosphate and stannous oxide as raw materials, P 2 o 5 The molar ratio to Sn is 0.3, the raw materials are mixed evenly and then heat-treated at 900°C for 15 minutes, and then water quenched to pulverize the obtained glass slag to obtain PS glass powder. Weigh 1.0 grams of PS glass powder, 5 grams of stannous oxalate, 0.4 grams of antimony trioxide, 0.25 grams of cerium oxide, 0.2 grams of cobalt oxide, mix the above raw materials, press and shape, and then heat treat at 500 degrees 2 hours, obtain product c, the scanning electron micrograph of product c sees Figure 1c , powder X-ray diffraction pattern see Figure 2c , The resistance-temperature curve 3c of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com