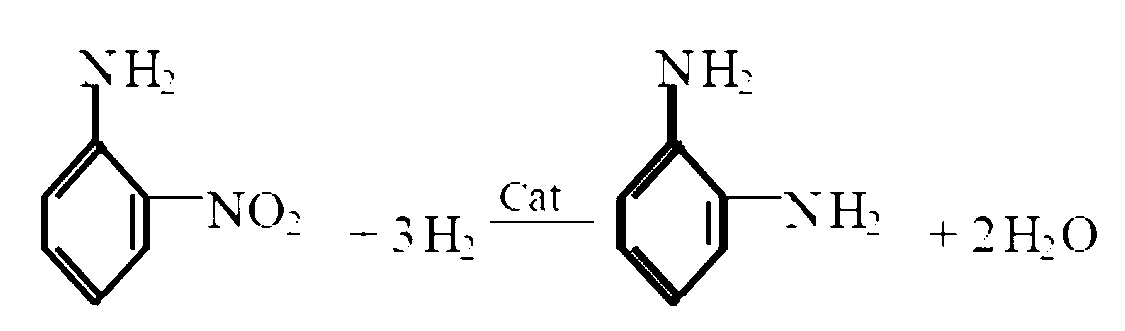

Preparation method of o-phenylenediamine

A technology of o-phenylenediamine and o-nitroaniline, which is applied in the field of preparation of o-phenylenediamine, can solve the problems of reduced safety and cleanliness, increased equipment investment and energy consumption, and increased product post-processing procedures, so as to achieve easy operation , Improve production capacity, save equipment investment and production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

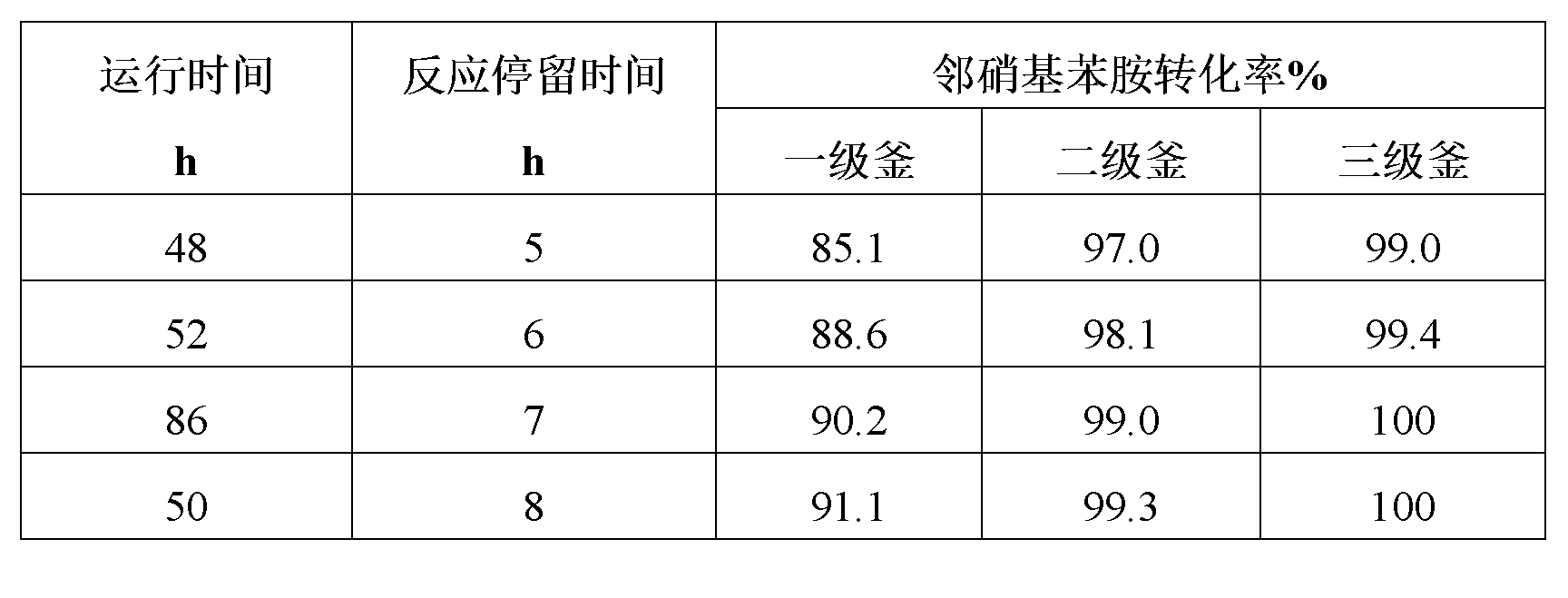

Embodiment 1

[0029] Coconut shell carbon with a particle size of 75 μm was used as the activated carbon carrier, and its specific surface area was 1500 m 2 / g, the ash content is 1.5%, weigh 50g of the above activated carbon, add 1000ml of 10wt% hydrochloric acid to it, heat and boil at 80°C for 4h, filter and wash with deionized water until neutral, filter and dry at 110°C. Add 400ml of 20wt% nitric acid to the dried activated carbon, heat and cook at 60°C for 4 hours, filter and wash with deionized water until neutral, filter, dry at 110°C, add 200ml of deionized water to the filter cake Prepared as charcoal slurry.

[0030] Weigh 1.67g of palladium chloride and 1.33g of chloroplatinic acid hexahydrate and dissolve them in 50ml of 20wt% dilute hydrochloric acid respectively, and mix the above two solutions to obtain 100ml of uniform metal salt mixture. Add it to the carbon slurry and stir at 30°C for 2 hours. At the same time, add 10% sodium carbonate to adjust the pH to 9.5. Continue t...

Embodiment 2

[0032] Apricot shell carbon with a particle size of 75 μm was used as the activated carbon carrier, and its specific surface area was 1200 m 2 / g, the ash content is 2%, weigh 50g of the above activated carbon, add 1000ml of 10wt% hydrochloric acid to it, heat and boil at 80°C for 4h, filter and wash with deionized water until neutral, filter and dry at 110°C. Add 400ml of 20wt% nitric acid to the dried activated carbon, heat and cook at 60°C for 4 hours, filter and wash with deionized water until neutral, filter, dry at 110°C, add 200ml of deionized water to the filter cake Prepared as charcoal slurry.

[0033]Weigh 1.67g of palladium chloride and 1.33g of chloroplatinic acid hexahydrate and dissolve them in 50ml of 20wt% dilute hydrochloric acid respectively, and mix the above two solutions to obtain 100ml of uniform metal salt mixture. Add it to the carbon slurry and stir at 30°C for 2 hours. At the same time, add 10% sodium hydroxide to adjust the pH to 9.6. Continue to s...

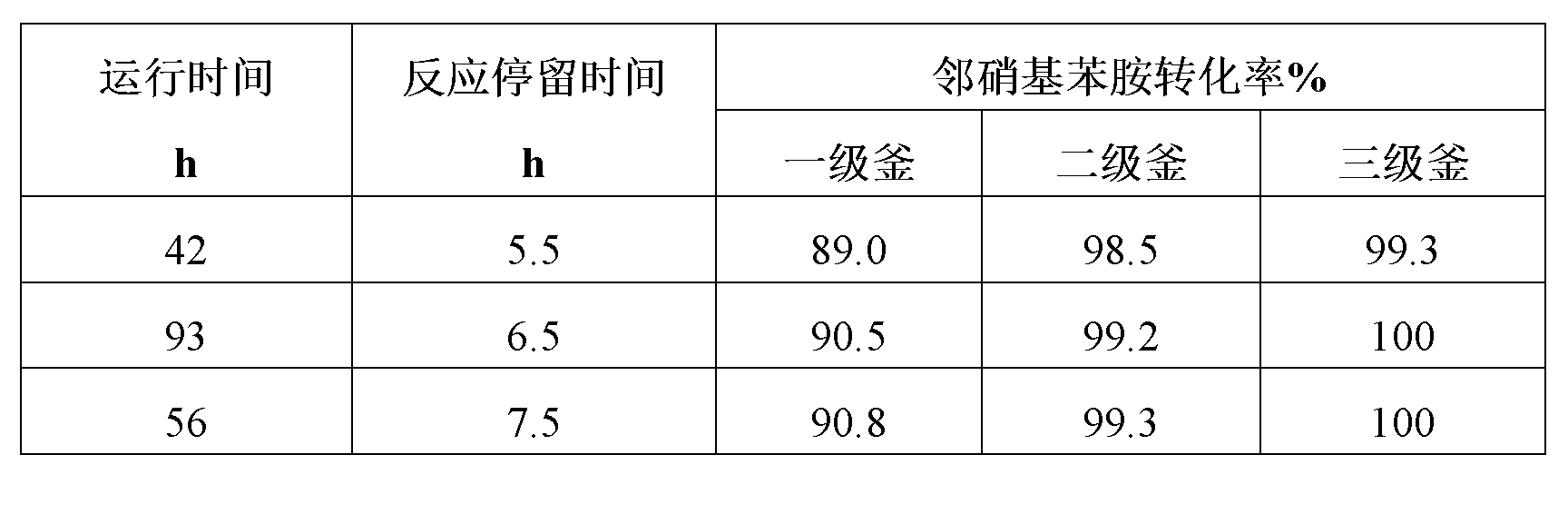

Embodiment 3

[0035] Coconut shell carbon with a particle size of 75 μm was used as the activated carbon carrier, and its specific surface area was 1500 m 2 / g, the ash content is 1.5%, weigh 50g of the above activated carbon, add 1000ml of 10wt% hydrochloric acid to it, heat and boil at 80°C for 4h, filter and wash with deionized water until neutral, filter and dry at 110°C. Add 400ml of 20wt% nitric acid to the dried activated carbon, heat and cook at 60°C for 4h, filter, wash with deionized water until neutral, filter, dry at 110°C, add 200ml of deionized water to make carbon slurry.

[0036] Weigh 2.0g of palladium chloride and 0.8g of chloroplatinic acid hexahydrate and dissolve them in 50ml of 20wt% dilute hydrochloric acid respectively, and mix the above two solutions to obtain 100ml of uniform metal salt mixture. Add it to the carbon slurry and stir at 30°C for 2 hours. At the same time, add 10% sodium carbonate to adjust the pH to 9.5. Continue to keep warm for 4 hours and then pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com