Preparation method for trimethylamine oxide

A technology for oxidizing trimethylamine and trimethylamine, which is applied in the direction of organic chemistry, can solve the problems of strong corrosivity of auxiliary hydrochloric acid, incomplete reaction of trimethylamine, complicated separation and purification process, etc., so as to reduce the activation energy of reaction, avoid the loss of raw materials, and improve Effects on Product Yield and Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

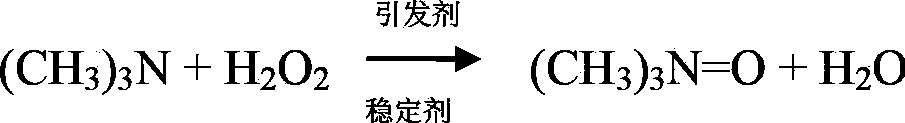

Image

Examples

Embodiment 1

[0061] At room temperature, 165.2 g of an aqueous solution of trimethylamine with a mass fraction of 25.06% was added to the reaction flask, and 51.0 g of an aqueous solution of hydrogen peroxide with a mass fraction of 47.27% was slowly added dropwise under stirring. Water bath control, to avoid excessive temperature rise caused by exothermic reaction, resulting in the decomposition of raw material hydrogen peroxide. Until all the hydrogen peroxide solution is dropped (the molar ratio of trimethylamine to hydrogen oxide is 1:1.01), the electric heating system and the cooling water system are comprehensively controlled, and the temperature is adjusted at 70°C to 75°C for 6 hours, and the reaction is terminated to obtain Oxidize the trimethylamine solution, cool down until the product crystallizes out; let it stand at room temperature to make the crystallization complete. Suction filtration, separation of crystals and mother liquor. Dry the crystals in an oven (40°C-45°C), dis...

Embodiment 2

[0063] At room temperature, 131.2 g of an aqueous solution of trimethylamine with a mass fraction of 30.94% was added to the reaction flask, and 45.0 g of an aqueous solution of hydrogen peroxide with a mass fraction of 53.45% was slowly added dropwise under stirring. Water bath control, to avoid excessive temperature rise due to exothermic reaction, resulting in the decomposition of raw material hydrogen peroxide. After all the hydrogen peroxide solution is dripped (the molar ratio of trimethylamine to hydrogen peroxide is 1:1.03), the electric heating system and the cooling water system are comprehensively controlled and the temperature is adjusted to 70°C to 75°C for 6 hours to obtain oxidation Trimethylamine solution, cool down until the product crystallizes out; let stand to make the crystallization complete. Suction filtration, separation of crystals and mother liquor. Dry the crystals in an oven (45°C-50°C), distill and concentrate the mother liquor under reduced press...

Embodiment 3

[0065] At room temperature, 165.3 g of trimethylamine aqueous solution with a mass fraction of 23.46% was added to the reaction flask, and 67.6 g of a hydrogen peroxide solution with a mass fraction of 41.26% was slowly added dropwise under stirring. During the reaction process, the water bath is controlled until all the hydrogen peroxide solution is dropped (the molar ratio of trimethylamine to hydrogen oxide is 1:1.25), the electric heating system and the cooling water system are comprehensively controlled, and the temperature is adjusted within the range of 65°C to 70°C , reacted for 6 hours to obtain a trimethylamine oxide solution, stirred and cooled until the product crystallized, and stood at room temperature to complete the crystallization. The crystals were separated from the mother liquor. Dry the crystals in an oven (45°C-50°C), concentrate the mother liquor under reduced pressure (temperature 50°C-70°C), separate the crystals from the mother liquor, dry the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com