Method for synthesizing sulfur-containing bisphenol compound antioxidant

A technology of phenolic compounds and antioxidants, which is applied in the field of optimizing and synthesizing sulfur-containing bisphenol compound antioxidants, can solve the problems of increased circulation of recovered solvents, decreased volumetric production capacity, and decreased utilization of reactors, and facilitates industrialization The effect of production, reduction of recycling times, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

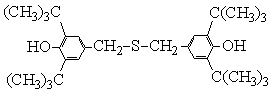

Image

Examples

Embodiment 1

[0030] In the GST-2 type stainless steel autoclave with magnetic stirring, 103g of raw material 2,6-di-tert-butylphenol, 9.78g of crystallization nucleating agent (60~90# 7.72g, polyethylene glycol 2.06g) were sequentially added , 30.0g of paraformaldehyde, 709g of 62% ethanol aqueous solution, 40g of 70% sodium hydrosulfide, after nitrogen replacement, start stirring and heating, fully mix the reaction raw materials in the kettle, when the temperature rises to 50~53°C, stop heating, The heat preservation reaction was carried out for 40 minutes, and the reaction was completed. Cool down to 20~30°C, filter, separate the reaction mother liquor, and collect; the separated solid product is washed with 55~75% ethanol aqueous solution to obtain the white crystal methylene-4426-S antioxidant product, purity: 98.8%, Melting point: 142.0~143.5°C, yield 97.6%.

Embodiment 2

[0032] In the GST-2 type stainless steel autoclave with magnetic stirring, 103g of raw material 2,6-di-tert-butylphenol, 9.78g of crystallization nucleating agent (60~90# 7.72g, polyethylene glycol 2.06g) were sequentially added , 28.5g of paraformaldehyde, 709g of 62% ethanol aqueous solution, 40g of 70% sodium hydrosulfide, after nitrogen replacement, start stirring and heating, fully mix the reaction raw materials in the kettle, when the temperature rises to 50~53°C, stop heating, The heat preservation reaction was carried out for 40 minutes, and the reaction was completed. Cool down to 20~30°C, filter, separate the reaction mother liquor, and collect; the separated solid product is washed with 55~75% ethanol aqueous solution to obtain the white crystal methylene-4426-S antioxidant product, purity: 99.1%, Melting point: 142.6~144.1°C, yield 97.8%.

Embodiment 3

[0034] In the GST-2 type stainless steel autoclave with magnetic stirring, 103g of raw material 2,6-di-tert-butylphenol, 7.21g of crystallization nucleating agent (5.15g of n-hexane, 2.06g of polyethylene glycol) were added successively. Formaldehyde 31.5g, 55% ethanol aqueous solution 618g, 70% sodium hydrosulfide 36g, after nitrogen replacement, start stirring and heating, fully mix the reaction raw materials in the kettle, when the temperature rises to 54~56°C, stop heating, keep warm for 60 minutes, the reaction is over. Cool down to 20~30°C, filter, separate the reaction mother liquor, and collect; the separated solid product is washed with 55~75% ethanol aqueous solution to obtain the white crystal methylene-4426-S antioxidant product, purity: 98.6%, Melting point: 142.5~144.1°C, yield 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com