Integrated sarciniform radiation preheating hybrid heat recovery device with flue gas chilling function

A heat recovery device and hybrid technology, applied in the manufacture of combustible gas, chemical industry, climate sustainability, etc., can solve the problems of increasing energy consumption of gasification device, increasing equipment investment, occupying large space, etc., and achieving energy recovery and utilization The effect of high efficiency, improved energy utilization, convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

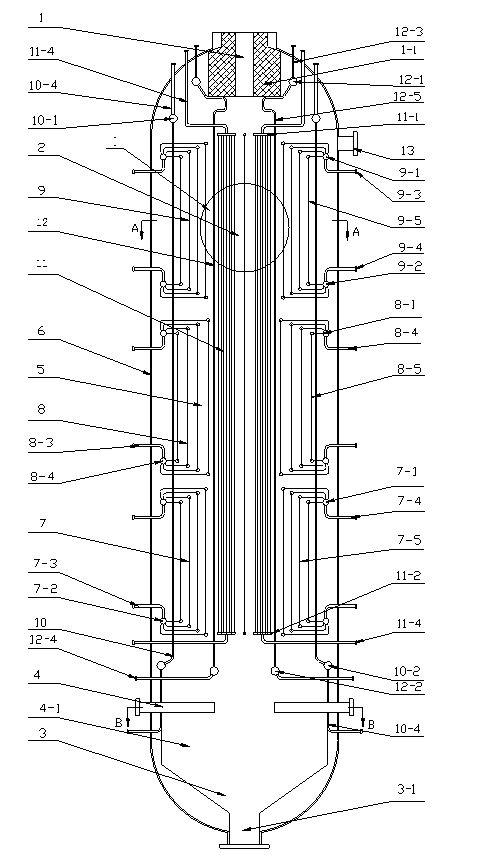

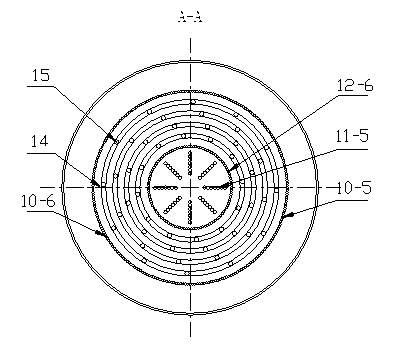

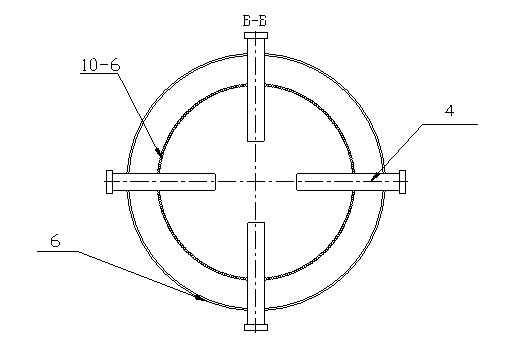

[0032] Such as Figure 1-4 As shown, the integrated beam radiation preheating hybrid heat recovery device with flue gas quenching includes syngas inlet 1, radiation heat exchange component 2, flue gas quenching component 4, slag pool 3, and convective heat transfer component 5 , pressure shell 6, synthesis gas outlet 13.

[0033] The synthesis gas inlet 1 is located at the top of the pressure housing 6, the synthesis gas outlet 13 is located at the upper end of the side wall of the pressure housing 6, the slag pool 3 is arranged at the bottom of the pressure housing 6, and the bottom of the slag pool 3 is connected to the pressure housing 6 The lower slag port 3-1 is formed together; the radiation heat exchange component 2 is fixed on the upper part of the pressure shell 6 to fully exchange heat with the gas with heat; the flue gas quenching component 4 is fixed on the bottom of the slag pool 3 The upper end is located at the lower end of the radiation heat exchange assembly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap