Ferrotitanium oxide nano-tube array photoanode, preparation method and applications thereof

A technology of nanotube array and titanium-iron alloy, which is applied in the field of material chemistry, can solve the problems that the activity of composite photocatalysts cannot be effectively exerted and the high specific surface area is reduced, and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The preparation process and characterization of the titanium-iron alloy oxide nanotube array photoanode, the specific steps are as follows:

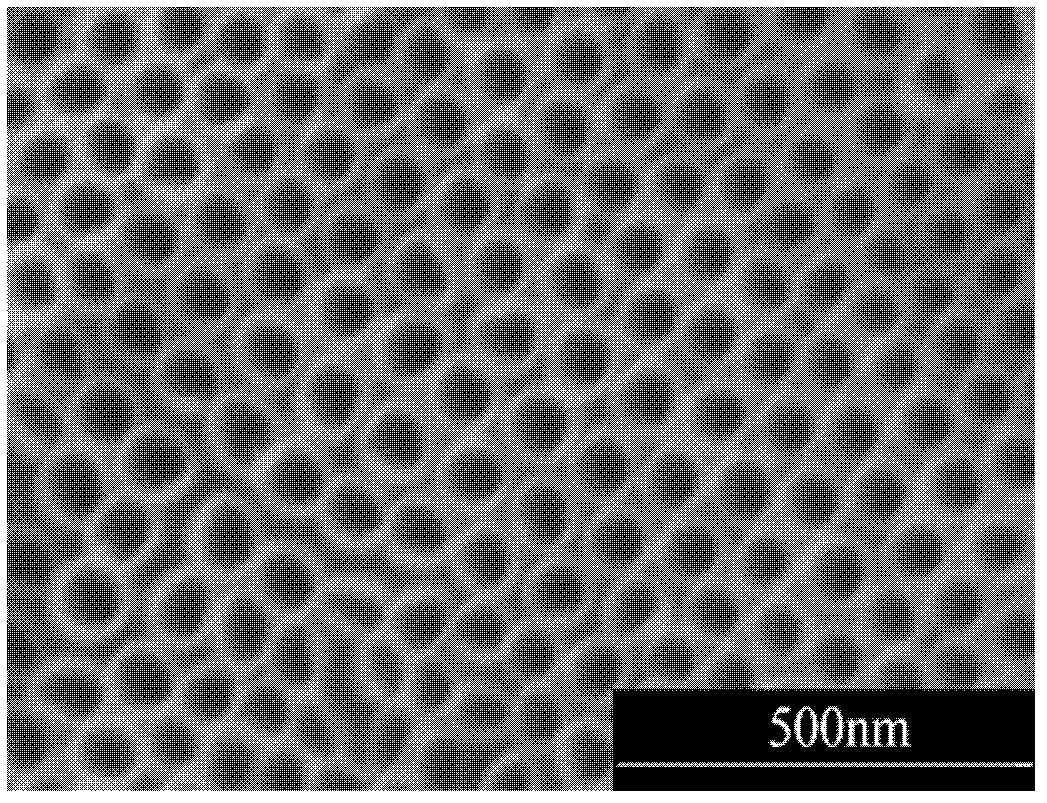

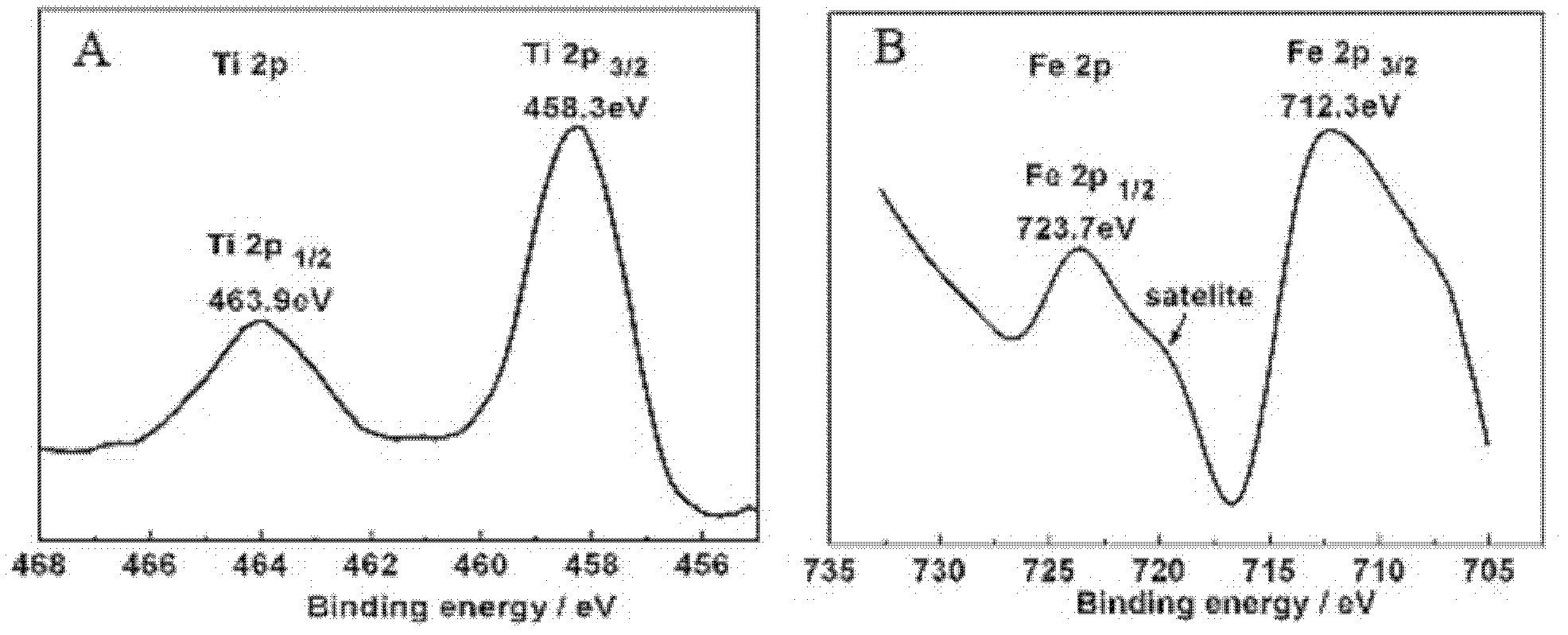

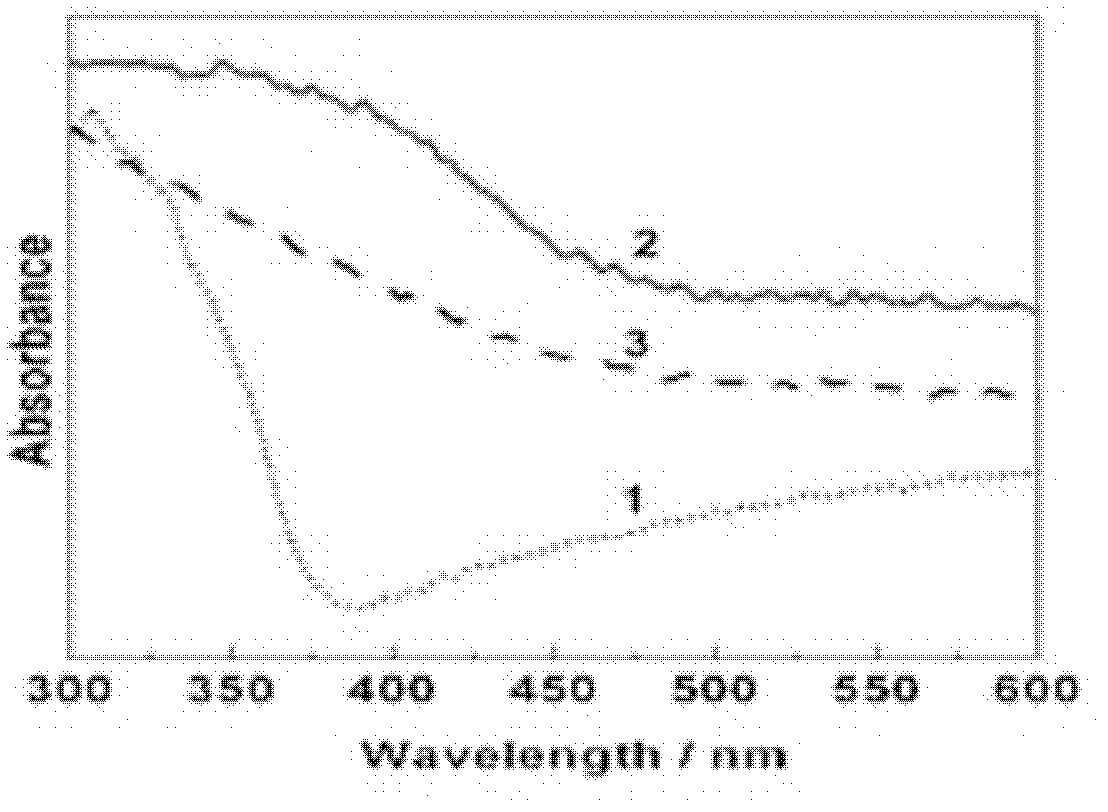

[0028]Mix Ti plate (purity 99.9%) and Fe particles (purity 99.99%) in a certain ratio, and under the protection of argon atmosphere, obtain titanium-iron alloy in a high-temperature argon arc melting furnace, and use a wire cutting machine to cut it into 15× The exact mass percentage of Fe in the alloy was determined to be 6% by inductively coupled plasma-atomic emission spectrometry (Optima 2100, Perkin-Elmer) for a sample with a size of 50×1 mm. After the titanium-iron alloy sheet is polished with 100# and 500# sandpaper in turn, it is polished into a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in distilled water and acetone for 15 minutes. At room temperature, the pretreated titanium-iron alloy sheet is used as the anode, the platinum sheet electrode is used as the counter electrode, and th...

Embodiment 2

[0036] A preparation process of a titanium-iron alloy oxide nanotube array photoanode, the specific steps are as follows:

[0037] Mix Ti plate (purity 99.9%) and Fe particles (purity 99.99%) in a certain ratio, and under the protection of argon atmosphere, obtain titanium-iron alloy in a high-temperature argon arc melting furnace, and use a wire cutting machine to cut it into 15× The exact mass percentage of Fe in the alloy was determined to be 4% by inductively coupled plasma-atomic emission spectrometry (Optima2100, Perkin-Elmer) for a sample with a size of 50×1 mm. After polishing the titanium-iron alloy sheet with 100# and 500# sandpaper in turn, polish it into a mirror surface with metallographic sandpaper, and then ultrasonically clean it in distilled water and acetone for 10 minutes respectively. At room temperature, the pretreated titanium-iron alloy sheet is used as the anode, the platinum sheet electrode is used as the counter electrode, the electrode distance is 1c...

Embodiment 3

[0041] The preparation process of the titanium-iron alloy oxide nanotube array photoanode, the specific steps are as follows:

[0042] Mix Ti plate (purity 99.9%) and Fe particles (purity 99.99%) in a certain ratio, and under the protection of argon atmosphere, obtain titanium-iron alloy in a high-temperature argon arc melting furnace, and use a wire cutting machine to cut it into 15× The exact mass percentage of Fe in the alloy was determined to be 6% by inductively coupled plasma-atomic emission spectrometry (Optima 2100, Perkin-Elmer) for a sample with a size of 50×1 mm. After the titanium-iron alloy sheet was polished with 100# and 500# sandpaper in turn, it was polished into a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in distilled water and acetone for 20 minutes each. At room temperature, the pretreated titanium-iron alloy sheet is used as the anode, the platinum sheet electrode is used as the counter electrode, the electrode distance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com