Ag4Bi2O5-doped MnO2 catalyst and preparation method for oxygen electrode

A technology of catalyst and oxygen electrode, which is applied in the field of preparation of oxygen reduction catalyst and oxygen electrode, can solve problems such as rapid decline and deterioration of catalyst chemical performance, and achieve the effects of improving discharge life, increasing catalytic active points, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

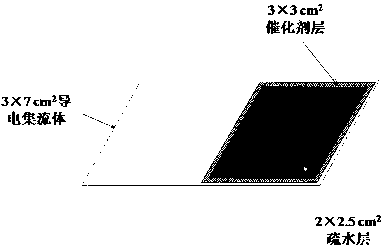

[0038] (1) MnO doped with 15% silver bismuthate by weight 2 0.9 g (wherein 0.125 g of silver bismuthate), 0.6 g of activated carbon, and 0.3 g of expanded graphite were stirred in a stirrer at a speed of 200 rpm for 20 minutes, then 4 ml of ethanol was added for dispersion, and finally 0.34 g of mass fraction was added dropwise Be 60% PTFE emulsion (the quality equivalent to pure PTFE is 0.2 g), continue to keep the original speed and stir evenly to obtain the slurry for subsequent use.

[0039] Weigh 1 g of the above slurry and apply it evenly on 5 pieces with an area of 3×7 cm 2 One end of nickel foam with a thickness of 1 mm, so that the coating effective area of the catalyst is 3 × 3 cm 2 , the nickel foam increased by about 0.2 g, and the nickel foam coated with the catalytic layer was dried in a drying oven at 60 °C for 3 h to obtain the catalyst layer.

[0040] (2) Weigh 0.2 g of camphor, 0.1 g of acetylene black and 1 ml of ethanol into a stirrer, stir at ...

Embodiment 2

[0043] Pure MnO 2 0.9 g or MnO doped with 10% by weight silver bismuthate 2 0.9g (wherein 0.09g of silver bismuthate), 0.6g of activated carbon and 0.3g of expanded graphite were stirred for 30 minutes at a speed of 150 rpm in a stirrer, then 4ml of ethanol was added for dispersion, and finally 0.34g of mass fraction was added dropwise 60% PTFE emulsion (mass equivalent to pure PTFE is 0.2 g), continue to maintain the original speed for stirring to obtain a slurry, take 1.5 g of the slurry and apply it evenly on 10 pieces with an area of 3 × 7 cm 2 One end of nickel foam with a thickness of 1 mm makes the coating effective area of the catalyst 3×3 cm 2 , the weight of each piece of nickel foam increased by 0.15 g, and the nickel foam coated with the catalytic layer was dried in a 40 °C drying oven for 4 h to obtain a catalyst layer. The formula of the hydrophobic layer was the same as that of Example 1 to obtain an oxygen electrode.

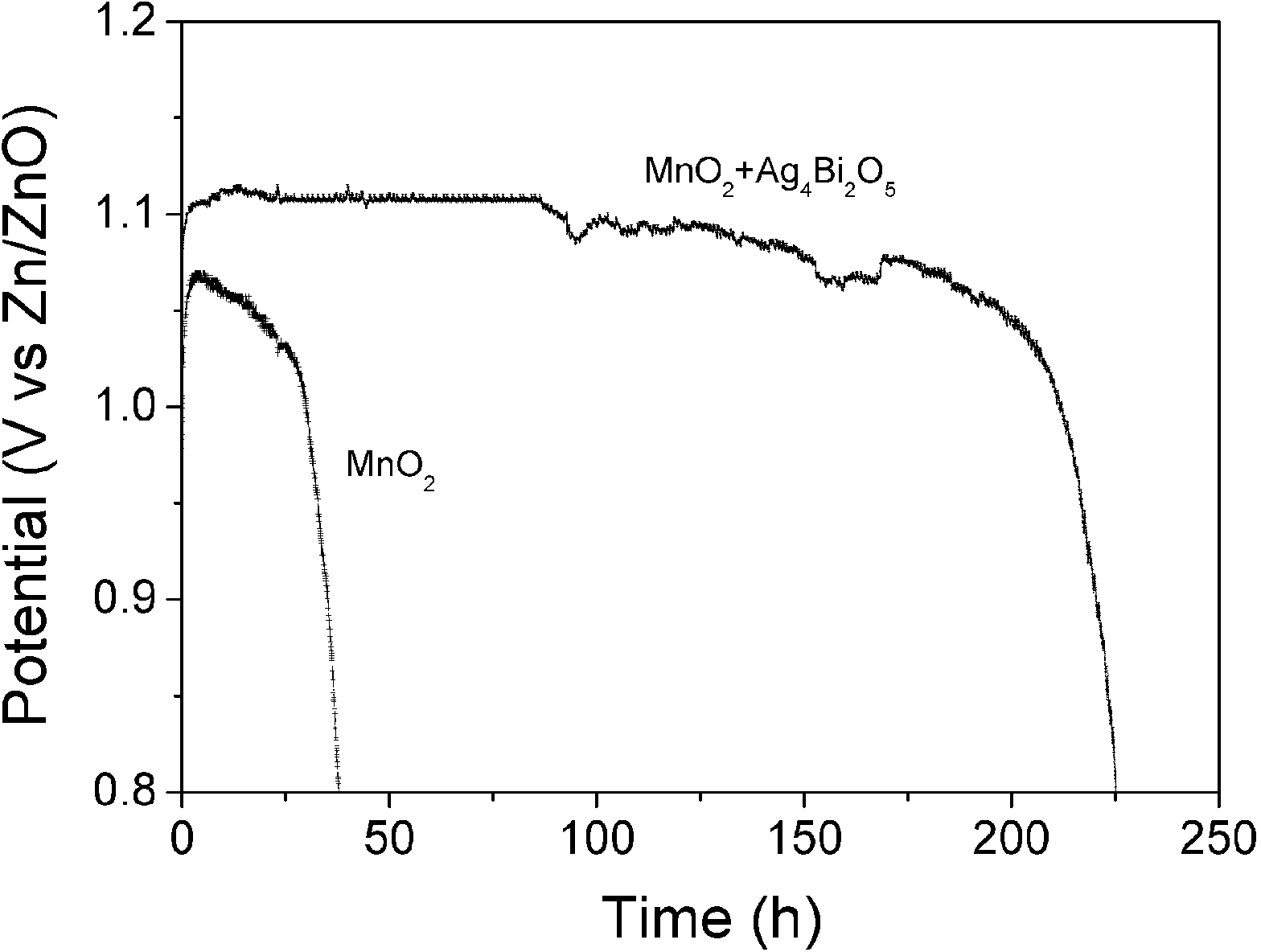

[0044] image 3 shows pure MnO2 a...

Embodiment 3

[0046] 0.6 g MnO doped with 10% silver bismuthate 2 (or pure MnO 2 ), 0.6 g of activated carbon and 0.6 g of expanded graphite were stirred in a stirrer at a speed of 200 rpm for 20 minutes, then 4 ml of ethanol was added for dispersion, and finally 0.34 g of PTFE emulsion with a mass fraction of 60% (equivalent to pure The quality of PTFE is 0.2 g), continue to keep the original speed and stir evenly, obtain the slurry for subsequent use. Apply the above slurry evenly on 10 pieces with an area of 3×7 cm 2 One end of nickel foam with a thickness of 1 mm, so that the coating effective area of the catalyst is 3 × 3 cm 2 , so that the nickel foam increased to about 0.2 g, and the nickel foam coated with the catalytic layer was dried in a drying oven at 80 °C for 2 h to obtain a catalyst layer. The formula of the hydrophobic layer was the same as that of Example 1 to obtain an oxygen electrode.

[0047] Attached by the cathodic polarization curve Figure 4 It can be seen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com