Silk fibroin base integrated osteochondral two-layer bracket, preparation and application thereof

A technology of silk fibroin and protein scaffolds, applied in coatings, prostheses, medical science, etc., can solve the problems of poor osteoinductivity and osteoconductivity, application limitations, etc., and achieve good cell adhesion and good biocompatibility , good bone repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

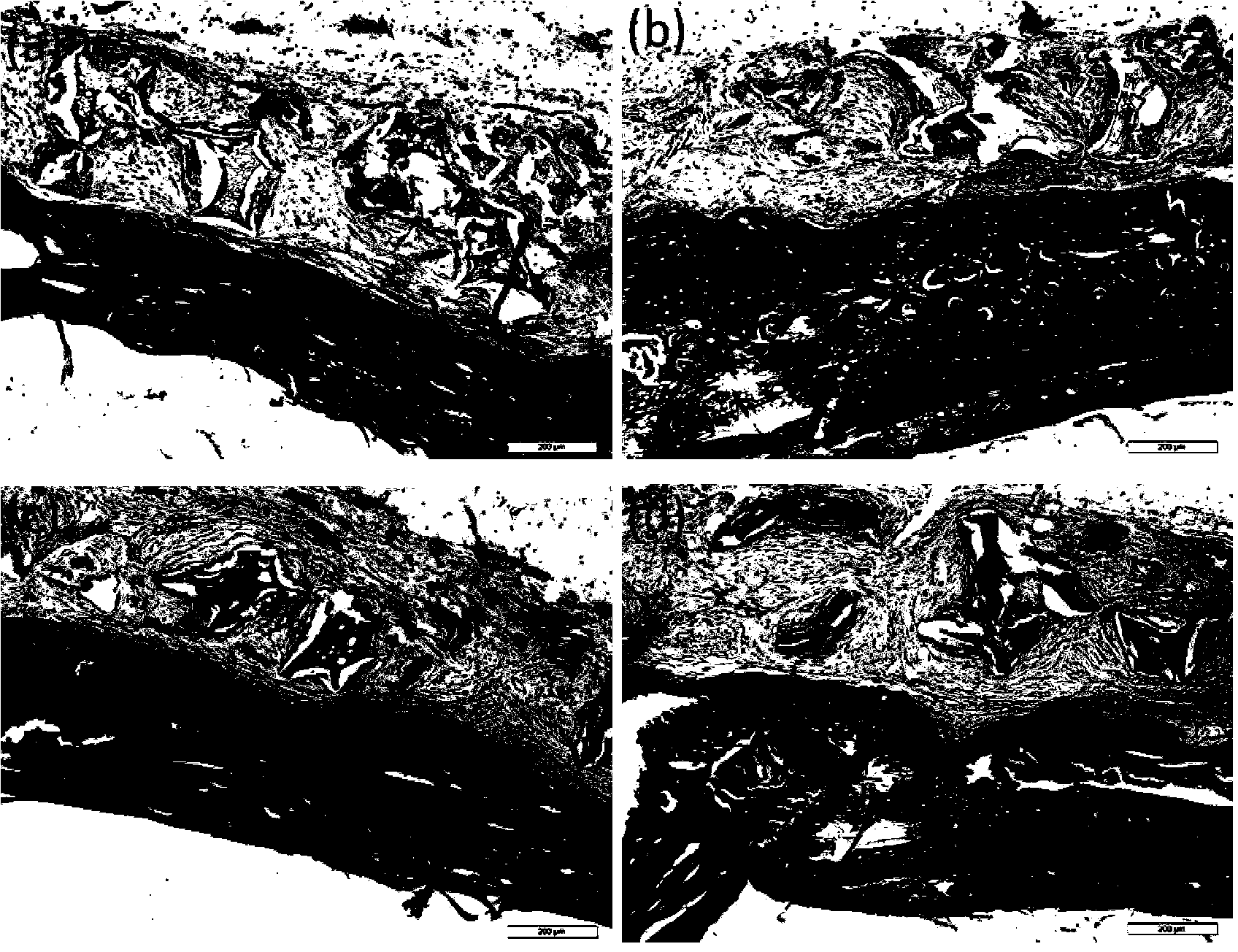

Examples

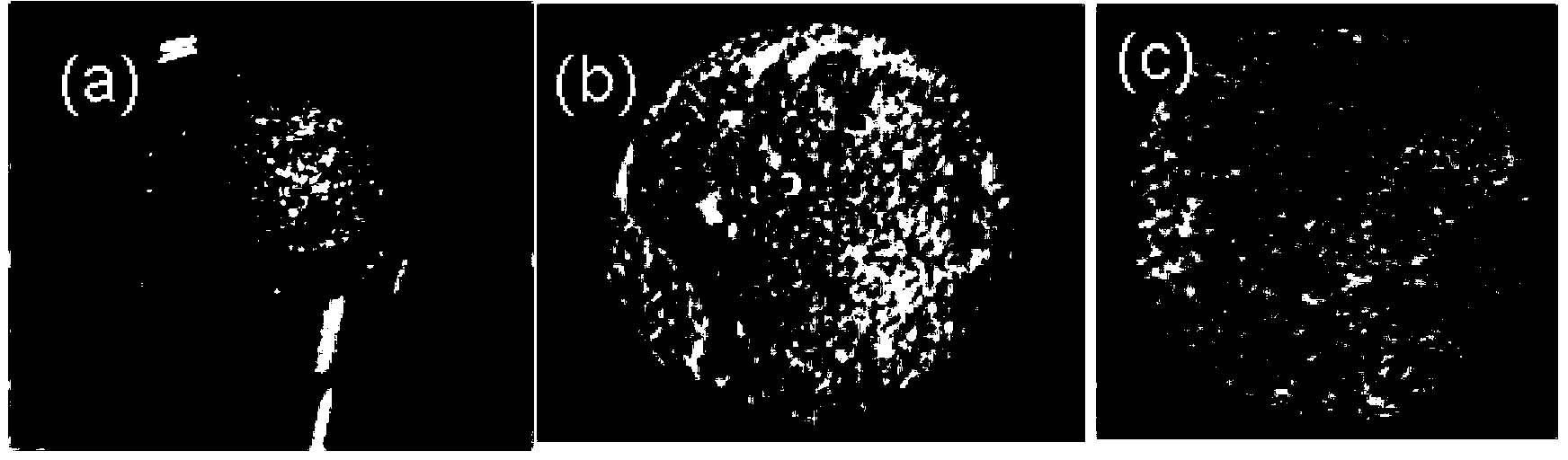

Embodiment 1

[0040] Preparation of silk fibroin solution: a) Degumming: put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 96°C water for 30min, wash with purified water, and repeat the process 3 times, remove the sericin, leave the silk fibroin, and dry the silk fibroin at 50°C to obtain 70g of dried silk fibroin for later use; b) Dissolving: the above-mentioned dried silk fibroin is Dissolve in 9.3M lithium bromide (LiBr) aqueous solution at a volume ratio of 0.2:1, bathe in water at 60°C for 90 minutes until the silk fibroin is fully dissolved, and obtain a mixed solution containing silk fibroin and a small amount of insoluble particles; c) Dialysis: Dilute the mixed solution with Dialyze the regenerated cellulose dialysis bag (molecular weight cut off 4000 Daltons), dialyze 12 times with sterile purified water of 10 times the volume of the mixed solution in 3 days, remove LiBr ions in the solution, and obtain th...

Embodiment 2

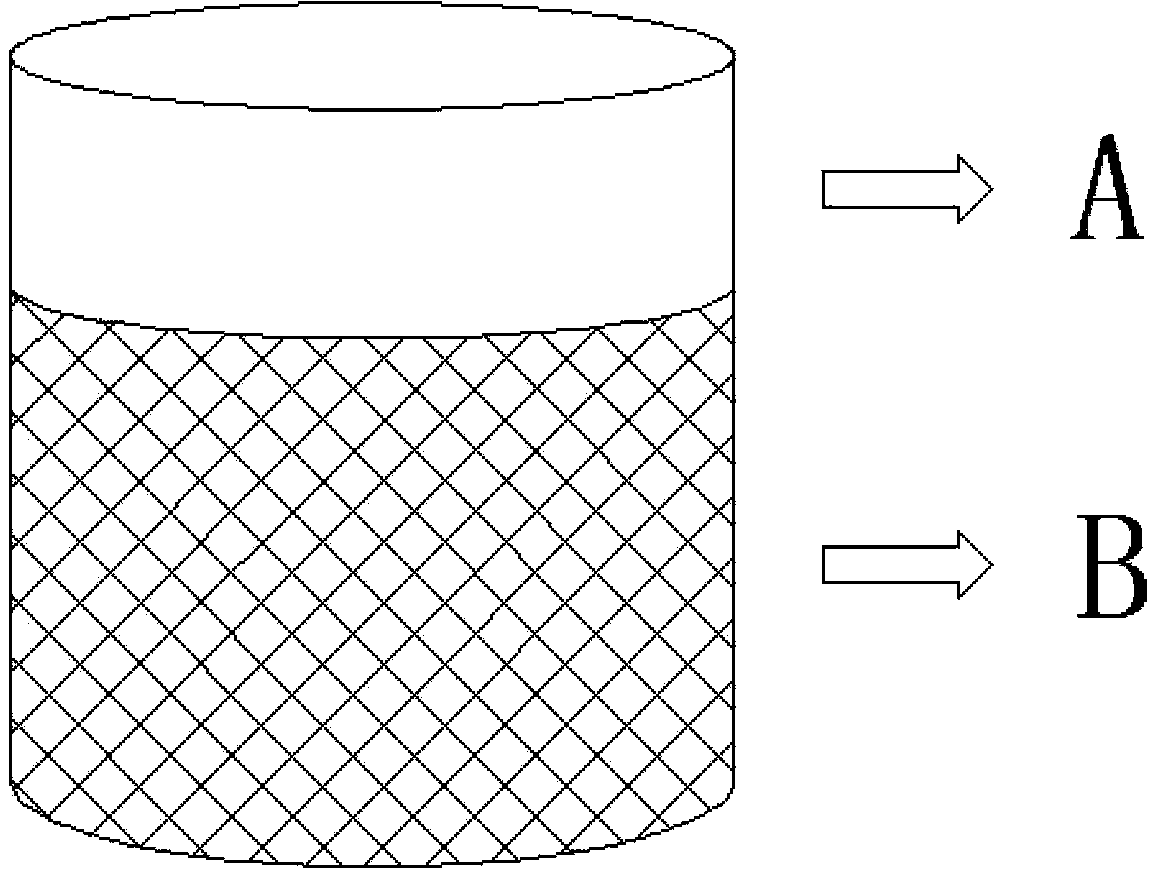

[0041] Example 2: Silk fibroin-based integrated osteochondral double-layer scaffold

[0042] (1) Silk fibroin solution: take 100 mg of silk fibroin after freeze-drying by the method of Example 1, dissolve it in deionized water at 4° C. for 3 days, and prepare 2 ml of a 50 mg / ml silk fibroin solution.

[0043] (2) Mold making: Use 5 1ml disposable volumetric syringes (both outer diameters are 6.5mm), including the barrel of the syringe and the push rod with the piston, as the mold; and the barrel needle of the disposable volumetric syringe The end of the seat is sintered and closed, and the mold cylinder is made of through holes dug on the closed surface. The hole diameter is equivalent to that of sodium chloride particles (ie, 45-50 μm), and the hole distance is 2 mm.

[0044] (3) Material compression: Pour 0.28g (0.2ml) of pre-ground NaCl particles with a particle size of 45-50μm into the mold, and then add 0.2ml of the silk fibroin solution in step (1). Quickly push in the ...

Embodiment 3

[0048] Example 3: Silk fibroin-based integrated osteochondral double-layer scaffold

[0049] (1) Silk fibroin solution: the silk fibroin prepared in Example 1 was dissolved in deionized water at 4° C. for 3 days to prepare 15 ml of a 60 mg / ml silk fibroin solution.

[0050] (2) Mold making: Use four 10ml disposable volumetric syringes (outside diameter of 16.5mm), including the cylinder of the syringe and the push rod with the piston, as the mold; and the needle seat of the cylinder of the disposable volumetric syringe This end is sintered closed and the said mold cylinder is made by digging through holes on the closed surface, the hole diameter is equivalent to that of sodium chloride particles (150-200 μm), and the hole distance is 3mm.

[0051] (3) Material compression: Pour 2.8g (2ml) of pre-ground NaCl particles with a particle size of 150-200μm into each mold, and then add 3ml of the silk fibroin solution prepared in step (1) at a rate of 3cm / Push in the solution at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com