Folding preventing less-layer graphene powder, components of composite material thereof, and application

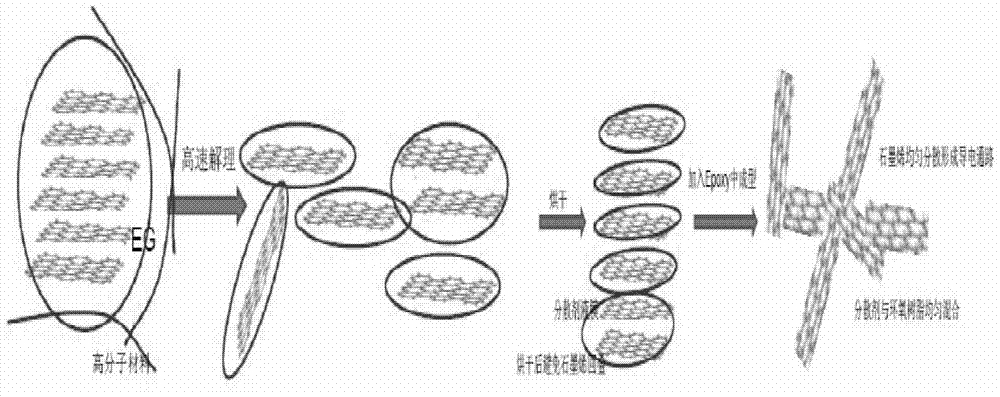

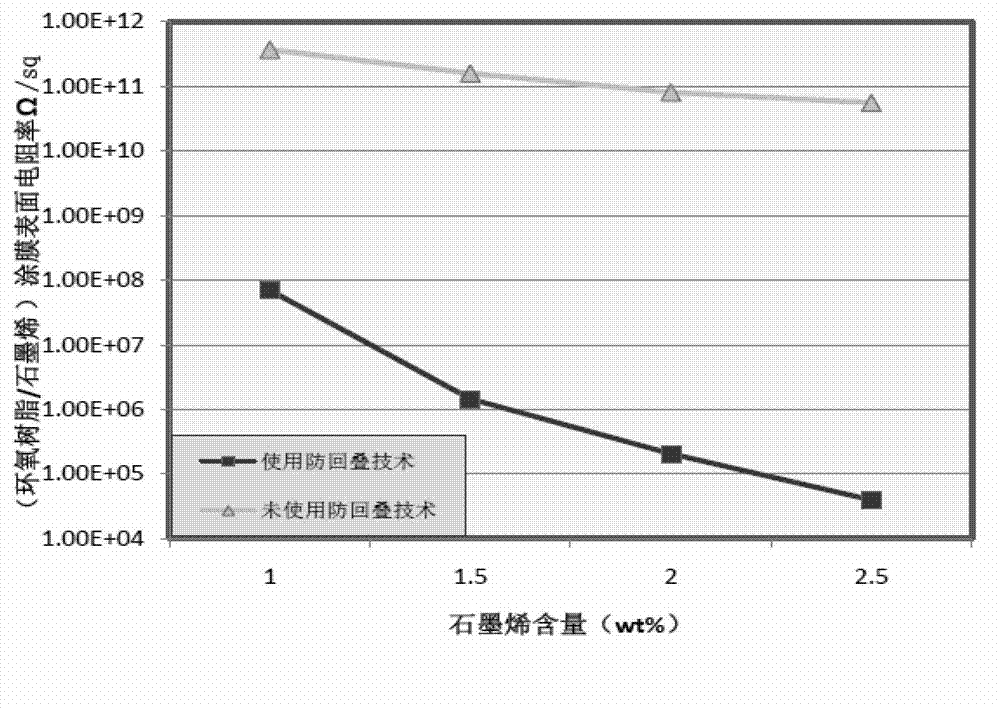

A technology of few-layer graphene and composite materials, which is applied in the direction of graphene, conductive coatings, nano-carbon, etc., can solve problems such as difficult to prevent graphene from secondary folding back, and achieve the goal of avoiding flying dust, reducing cleavage time, and easy peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of anti-backfolding few-layer graphene powder is carried out according to the following steps:

[0032] (1) Take 500g of natural graphite (100mesh) and add it to a mixed solution of 1500g of concentrated sulfuric acid and fuming nitric acid, add 750g of potassium chlorate to the solution at 5°C, and keep stirring for 96 hours. The mixture was filtered with filter paper and the residue was washed with 5wt% hydrochloric acid until no sulfate was detected, and then the residue was washed with deionized water until the pH was 6. The residue was dried in an oven at 70°C for 48 hours to obtain intercalated graphite.

[0033] (2) Put the intercalated graphite prepared in step (1) into a muffle furnace with nitrogen gas, set the temperature at 1050°C, and heat for 2 minutes to obtain expanded graphite;

[0034] (3) Add 90g of polyethylene oxide to 5610g of water in parts by weight, and stir evenly to make a mixed solution;

[0035] (4) adding the ...

Embodiment 2

[0039] A kind of preparation method of anti-backfolding few-layer graphene powder is carried out according to the following steps:

[0040] (1) Take 100g of natural graphite (100mesh) and add it to a mixed solution of 300g of concentrated sulfuric acid and fuming nitric acid, add 150g of potassium chlorate to the solution at 5°C, and keep stirring for 96 hours. The mixture was filtered with filter paper and the residue was washed with 5wt% hydrochloric acid until no sulfate was detected, and then the residue was washed with deionized water until the pH was 7. The residue was dried in an oven at 70°C for 48 hours to obtain intercalated graphite.

[0041] (2) Put the intercalated graphite prepared in step (1) into a muffle furnace with nitrogen gas, set the temperature at 1050°C, and heat for 2 minutes to obtain expanded graphite;

[0042](3) Add 1.5g of polyethylene glycol to 93.5g of water in parts by weight, and stir evenly to make a mixed solution;

[0043] (4) adding the ...

Embodiment 3

[0047] A kind of preparation method of anti-backfolding few-layer graphene powder is carried out according to the following steps:

[0048] (1) Take 70g of natural graphite (100mesh) and add it to a mixed solution of 210g of concentrated sulfuric acid and fuming nitric acid, add 90g of potassium chlorate to the solution at 10°C, and keep stirring for 96 hours. The mixture was filtered with filter paper and the residue was washed with 5wt% hydrochloric acid until no sulfate was detected, and then the residue was washed with deionized water until the pH was 6. The residue was dried in an oven at 70°C for 48 hours to obtain intercalated graphite.

[0049] (2) Put the intercalated graphite prepared in step (1) into a muffle furnace with nitrogen gas, set the temperature at 1050°C, and heat for 2 minutes to obtain expanded graphite;

[0050] (3) Add 10g of polyvinyl alcohol into 519g of water in parts by weight, stir evenly, then add 5g of sodium dodecylsulfonate and 1g of defoame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com