Catalyzing and decoloring integrated method for synthesizing environment-friendly plasticizer triethylhexyl (2-propylheptyl) citrate

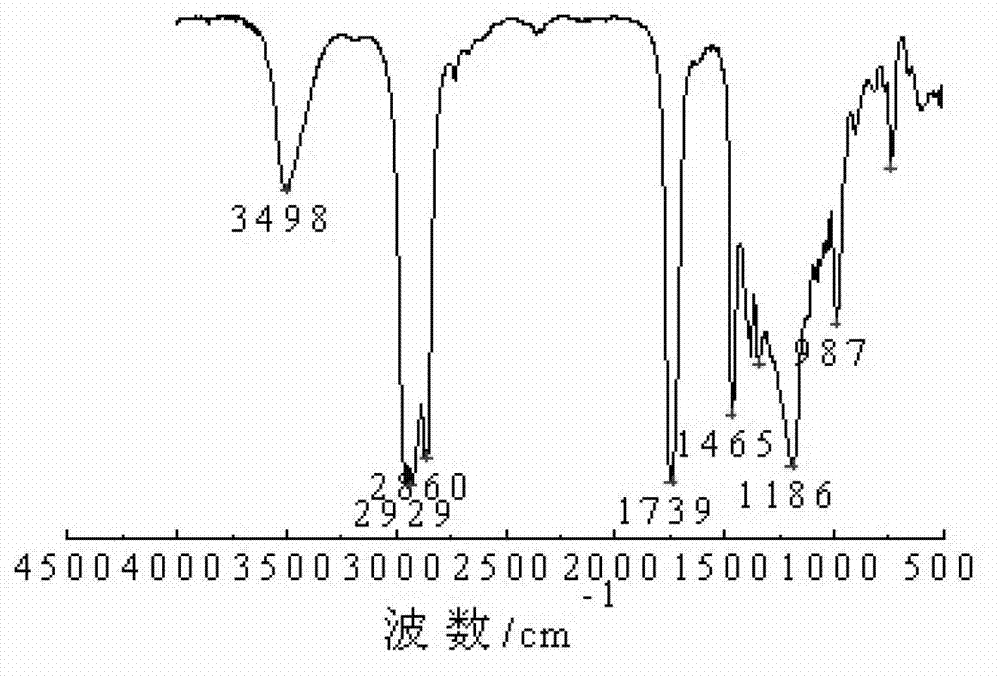

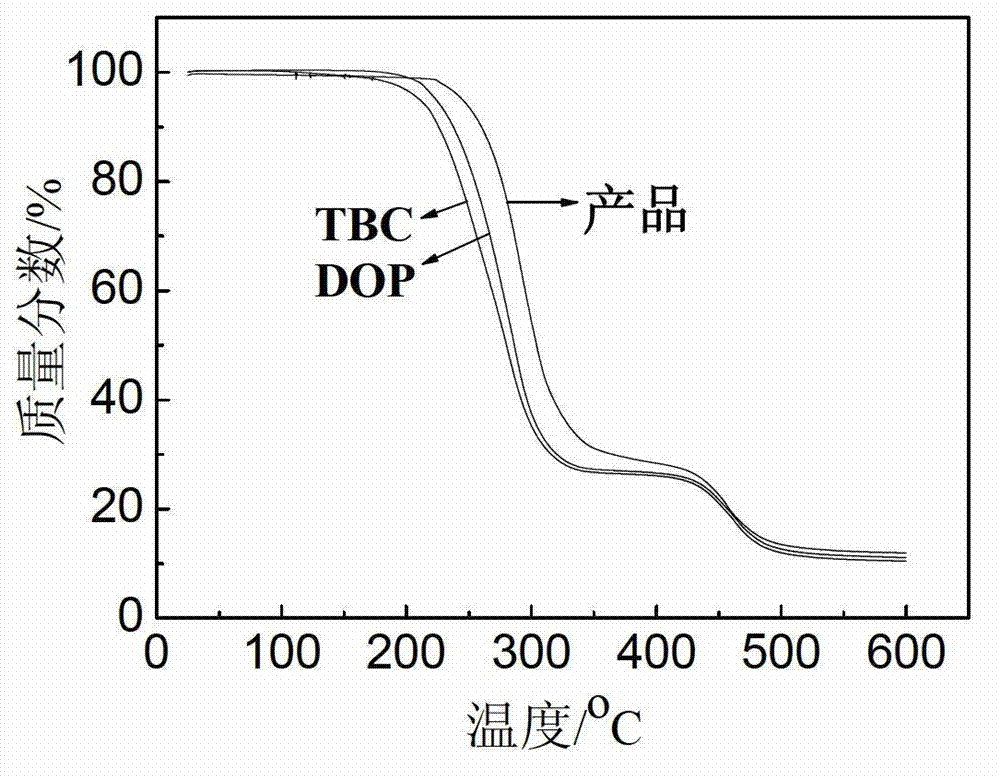

An environmentally friendly plasticizer, citric acid three technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid esters, etc., can solve the problem of deep color of target products, low product yield, and many side reactions And other problems, to achieve the effect of shortening the production cycle, simplifying the operation, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Catalyst immobilized preparation

[0026] Using a high-concentration p-toluenesulfonic acid solution as the active center precursor to immobilize the activated carbon to prepare a heterogeneous catalyst: Weigh 10g of powdered activated carbon, wash it with deionized water until neutral, activate it at 120°C for 2h, and soak it in 70g of activated carbon with a mass fraction of 50 % of p-toluenesulfonic acid aqueous solution, immobilized at room temperature for 35 hours, filtered, and dried to constant weight to obtain p-toluenesulfonic acid immobilized on activated carbon, abbreviated as C-pTSA, as a heterogeneous catalyst.

Embodiment 2

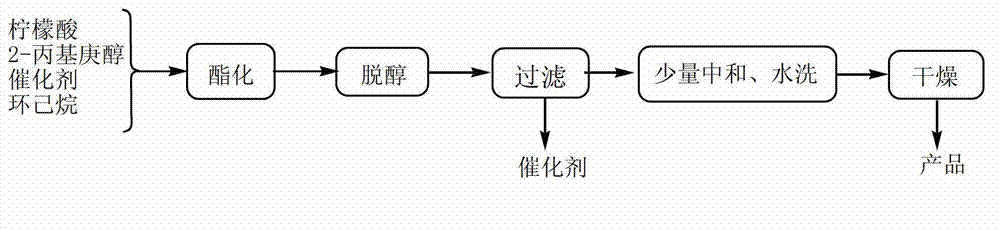

[0027] Embodiment 2 prepares three (2-propyl heptyl) citrates

[0028] Add 4.2kg of citric acid monohydrate, 11.7kg of 2-propylheptanol (the molar ratio of citric acid monohydrate to 2-propylheptanol is 1:3.7), 0.126kg of catalyst, and stir to raise the temperature to 110℃ ~150°C, the reaction time is 4h, and the esterification rate reaches 99.6%; the crude product is dealcoholized by vacuum distillation, the temperature is 140°C~150°C, and the vacuum degree is 0.09MPa. After the alcohol is no longer released, the catalyst is filtered out, and the filtrate is re- Carry out neutralization alkali washing and water washing. Neutralization alkali washing uses 5% sodium bicarbonate and 1% sodium hydroxide aqueous solution at a temperature of 50 ° C ~ 70 ° C. Water washing uses deionized water or distilled water at a temperature of 60 ℃~90℃; and finally dry to obtain the colorless product tris(2-propylheptyl) citrate.

Embodiment 3

[0029] Embodiment 3 prepares three (2-propyl heptyl) citrates

[0030] Add 4.2kg of citric acid monohydrate, 12.6kg of 2-propylheptanol (the molar ratio of citric acid monohydrate to 2-propylheptanol is 1:4.0), and 0.105kg of heterogeneous catalyst in the reaction kettle, stir and heat up to the temperature 110°C~150°C, reaction time 6h, the esterification rate reached 99.7%; the crude product was dealcoholized by vacuum distillation, the temperature was 140°C~150°C, and the vacuum degree was 0.09MPa. After the alcohol was no longer released, the catalyst was filtered out. The filtrate is then subjected to neutralization and alkali washing and water washing. The neutralization and alkali washing uses 5% sodium bicarbonate and 1% sodium hydroxide aqueous solution at a temperature of 50°C to 70°C, and deionized water or distilled water is used for water washing. The temperature is 60°C~90°C; finally, it is dried to obtain the colorless product tris(2-propylheptyl) citrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com