Severe alkalized soil conditioner and processing method thereof

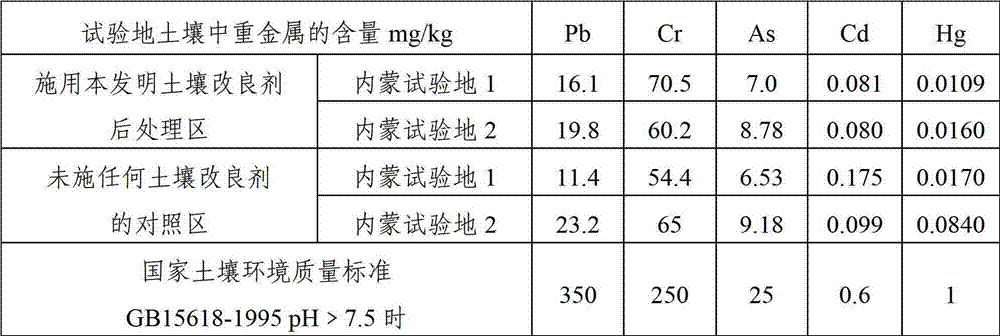

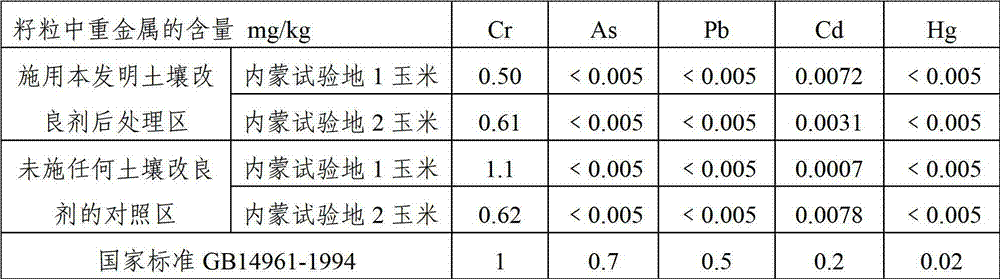

A soil conditioner and processing method technology, applied in the field of soil improvement, can solve the problems of excess heavy metals and harmful trace elements, high cost of soil improvement for farmers, and unsatisfactory effects, so as to overcome the imbalance of nutrient elements, improve soil fertility, and improve physical properties. effect of traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Improver: 92g of desulfurized gypsum, 1g of straw, 3g of furfural slag, 3g of biomass coke, 3g of weathered coal, 0.05g of urea, and 0.01g of microbial fertilizer.

[0057] 2. Processing method:

[0058] (1) Separately crush the straw and microbial fertilizer with a pulverizer, and pass through a 60-mesh sieve;

[0059] (2) Add the crushed straw, microbial fertilizer and the above-mentioned other raw materials into a mixer and mix them evenly, and then add them into a disc granulator for granulation to obtain a granular heavily alkalized soil conditioner.

[0060] 3. Improvement process (application of soil conditioner):

[0061] (1) The improved land shall be rough leveled first to remove the obvious concave and convex areas on the land;

[0062] (2) Carry out laser leveling, so that the slope of the farming block is 0.05%;

[0063] (3) The above-mentioned improvers are mixed and evenly applied to the soil surface (the depth of application is 25cm in the depth of...

Embodiment 2

[0067] 1. Improver: 88g of desulfurized gypsum, 3g of straw, 1g of furfural slag, 5g of biomass coke, 1g of weathered coal, 0.1g of urea, and 0.05g of microbial fertilizer.

[0068] 2. Processing method:

[0069] (1) Separately crush the straw and microbial fertilizer with a pulverizer, and pass through a 30-mesh sieve;

[0070] (2) Add the crushed straw, microbial fertilizer and the above-mentioned other raw materials into a mixer and mix them evenly, and then add them into a disc granulator for granulation to obtain a granular heavily alkalized soil conditioner.

[0071] 3. Improvement process (application of soil conditioner):

[0072] (1) The improved land shall be rough leveled first to remove the obvious concave and convex areas on the land;

[0073] (2) Carry out laser leveling, so that the slope of the farming block is 0.05%;

[0074] (3) The above-mentioned improvers are mixed and evenly applied to the soil surface (the depth of application is 24cm of the cultivate...

Embodiment 3

[0078] 1. Improver: 90g of desulfurized gypsum, 2g of straw, 2g of furfural slag, 4g of biomass coke, 2g of weathered coal, 0.08g of urea, and 0.03g of microbial fertilizer.

[0079] 2. Processing method:

[0080] (1) Separately crush the microbial fertilizer and straw with a pulverizer, and pass through a 40-mesh sieve;

[0081] (2) Put the crushed microbial fertilizer, straw and other raw materials mentioned above into a mixer and mix evenly, and then add them into a disc granulator for granulation to obtain a granular heavily alkalized soil conditioner.

[0082] 3. Improvement process (application of soil conditioner):

[0083] (1) The improved land shall be rough leveled first to remove the obvious concave and convex areas on the land;

[0084] (2) Carry out laser leveling, so that the slope of the farming block is 0.05%;

[0085] (3) The above-mentioned improvers are mixed and evenly applied to the soil surface (the depth of application is 22cm of the cultivated layer)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com