Formation method of groove-shaped semiconductor structure

A semiconductor and trench technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor process uniformity, easy generation of large pressure, deformation of silicon wafers, etc., to achieve low defect density, reduce Stress, Defect Prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

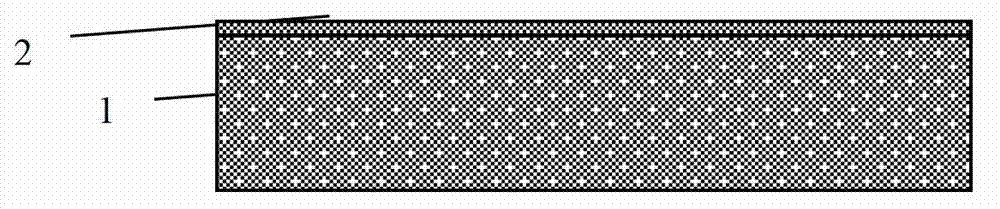

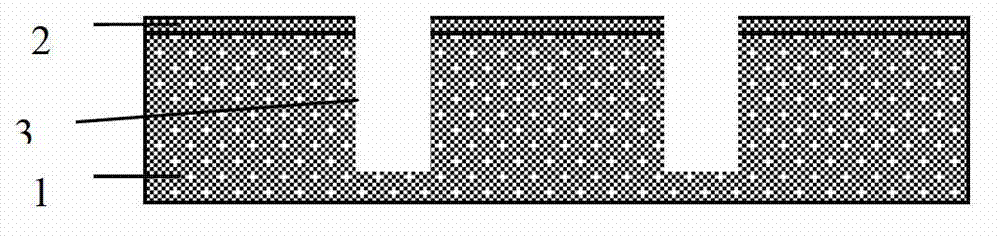

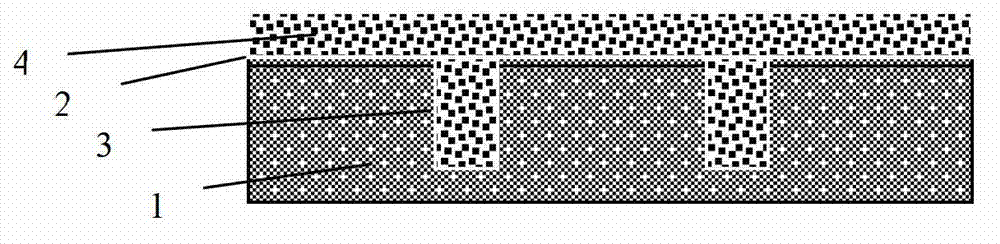

[0032] likeFigure 1A-Figure 1D As shown, the manufacturing process of this embodiment 1 includes the following steps:

[0033] 1) Dielectric layer growth. Dielectric film 2 is grown on silicon substrate or silicon epitaxy 1, and dielectric film 2 is SiO 2 , SiN, SiON at least one (see Figure 1A ), the growth of the dielectric film 2 can be grown by chemical vapor deposition or thermal oxidation, the growth temperature is 300-1300 degrees Celsius, and the growth pressure is 0.01-760 Torr; the thickness of the dielectric film 2 is 0.1-5.0 microns.

[0034] 2) Trench etching. Groove etching adopts anisotropic dry etching, and uses photoresist as a mask to etch a groove 3 in a predetermined area. The width of the groove 3 is 0.1-5.0 microns, and the depth of the groove 3 is 0.1 -10 µm (see Figure 1B ).

[0035] 3) C-containing polysilicon or amorphous silicon 4 filling. Fill the entire trench 3 with C-doped polysilicon or amorphous silicon (i.e. C-containing polysilicon or...

Embodiment 2

[0039] like Figure 2A-Figure 2D Shown, the manufacturing process of embodiment 2 comprises the following steps:

[0040] 1) Dielectric layer growth. Dielectric film 2 is grown on silicon substrate or silicon epitaxy 1, and dielectric film 2 is SiO 2 , SiN, SiON at least one (see Figure 2A ), the growth of the dielectric film 2 can be grown by chemical vapor deposition or thermal oxidation, the growth temperature is 300-1300 degrees Celsius, and the growth pressure is 0.01-760 Torr; the thickness of the dielectric film 2 is 0.1-5.0 microns.

[0041] 2) Trench etching. Groove etching adopts anisotropic dry etching, and uses photoresist as a mask to etch a groove 3 in a predetermined area. The width of the groove 3 is 0.1-5.0 microns, and the depth of the groove 3 is 0.1 -10 µm (see Figure 2B ).

[0042] 3) Polycrystalline SiC or amorphous SiC filling. Fill the entire trench 3 with SiC-doped polycrystalline SiC or amorphous SiC 5 (see Figure 2C ). Polycrystalline SiC...

Embodiment 3

[0046] like Figure 3A-Figure 3D Shown, the manufacturing process of embodiment 3 comprises the following steps:

[0047] 1) Trench etching. Groove etching adopts anisotropic dry etching, and uses photoresist as a mask to etch a groove 3 in a predetermined area on the silicon substrate or silicon epitaxy 1, and the width of the groove 3 is 0.1-5.0 microns , the depth of groove 3 is 0.1-10 microns (see Figure 3A ).

[0048] 2) Thermal oxide film growth on all silicon wafers. At a temperature of 700-1300 degrees Celsius, in O 2 , or H 2 O and O 2 Under the atmosphere, thermally oxidize the sidewall and top of trench 3 to form silicon oxide 6 of 0.01-0.5 microns (see Figure 3B ).

[0049] 3) C-containing polysilicon or amorphous silicon filling. Fill the entire trench with C-doped polysilicon or amorphous silicon (i.e. C-containing polysilicon or amorphous silicon4) (see Figure 3C ). C-containing polysilicon or amorphous silicon 4 adopts the method of chemical vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com