Synthetic method of polyaniline/carbon fiber composite material with nano-ordered structure

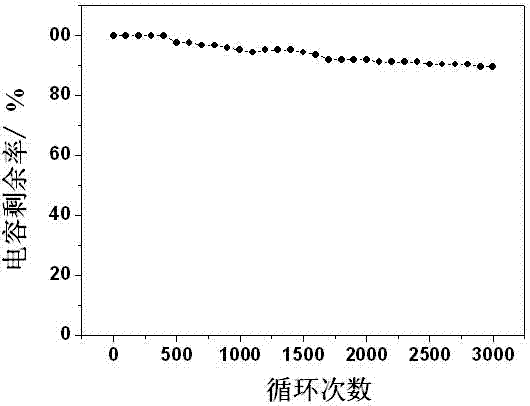

A technology of ordered structure and synthesis method, which is applied in the synthesis field of polyaniline/carbon fiber composite materials with nano-ordered structure, can solve the problems of composite material performance degradation, environmental hazards, cumbersome template removal process, etc., and achieve uniform size and easy operation , the effect of excellent electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

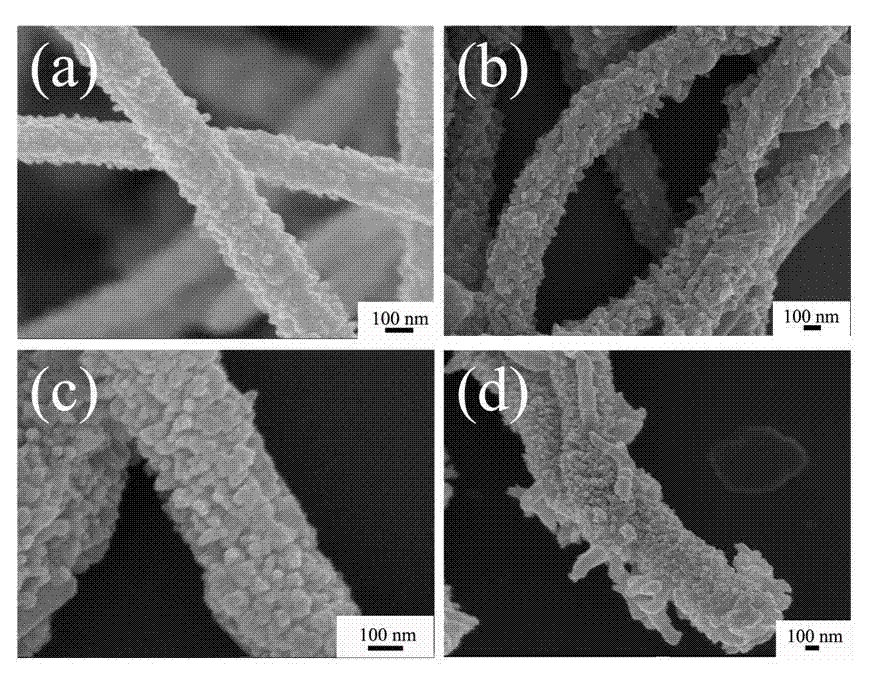

[0021] Examples 1-10 (the influence of the concentration of aniline on the nanometer size of polyaniline)

[0022] At room temperature, ultrasonically disperse 3 mg of CFs in 7 ml of 1mol / L HClO 4 System 1 was obtained in the solution. After the CFs were dispersed uniformly by ultrasonic, ANI was added, and the ultrasonic dispersion was continued to obtain System 2. At the same time, APS was ultrasonically dispersed in 3ml HClO with a concentration of 1mol / L at room temperature. 4 System 3 was obtained in the solution; mixed system 2 and system 3 obtained CFs / ANI / APS ternary system, wherein the molar ratio ANI:APS=1:1 was maintained, and the final concentration of carbon fiber was 0.3mg / ml respectively; CFs / ANI / The APS ternary system was quickly transferred to an ice-water bath, mechanically stirred at a constant temperature of 0 °C for 3 h, collected and dried, and a polyaniline / carbon fiber composite material with a nano-ordered structure was obtained.

[0023] Among them,...

Embodiment 11~12

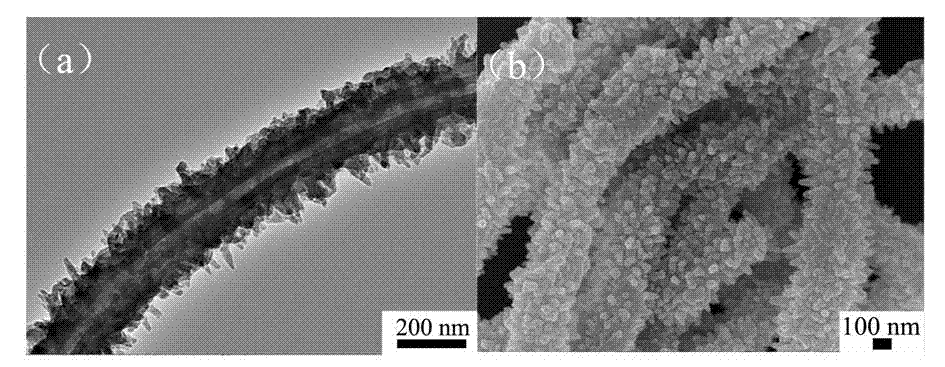

[0026] Embodiments 11-12 (the influence of reaction time on the nanometer size of polyaniline)

[0027] After the CFs / ANI / APS ternary system was transferred to an ice-water bath, the stirring reaction was carried out at 7 h and 14 h respectively, and the others were the same as in Example 2. Figure 4 a~c are the transmission electron microscope comparison diagrams of the polyaniline / carbon fiber composite material with nano-ordered structure prepared in Examples 2, 11, and 12. From the figure, it can be clearly seen that the length of polyaniline changes with the increase of reaction time. long.

Embodiment 13

[0029] CFs dosage is 1mg, ANI dosage is 18.624mg, APS dosage is 22.82mg, HClO 4 The concentration of the solution is 0.5mol / L, keep the CFs / ANI / APS ternary system, the molar ratio ANI:APS=2:1, constant temperature mechanical stirring at -10°C, the others are the same as in Example 2, and a nano-ordered structure is also obtained polyaniline / carbon fiber composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com