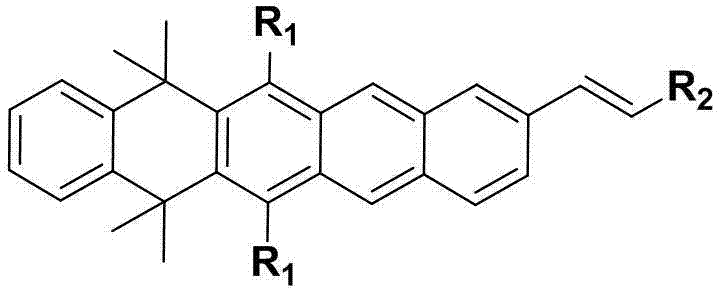

Dihydro-pentacene-olefin organic light-emitting material, preparation method and application of dihydro-pentacene-olefin organic light-emitting material

A technology for luminescent materials and pentaphenylene olefins, which is applied in the preparation of luminescent materials, organic compounds, organic chemistry, etc., can solve the problems of short life and low luminous efficiency, and achieve the effects of improved performance, high luminous efficiency and good application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

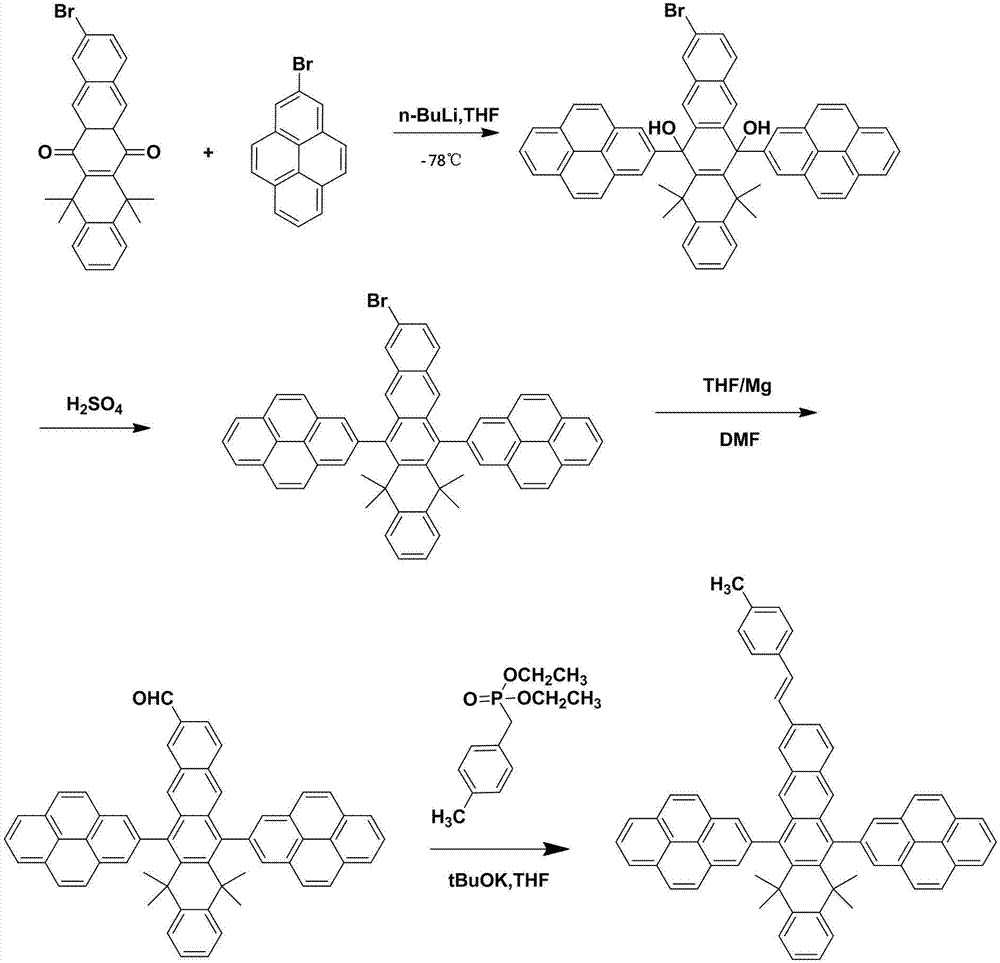

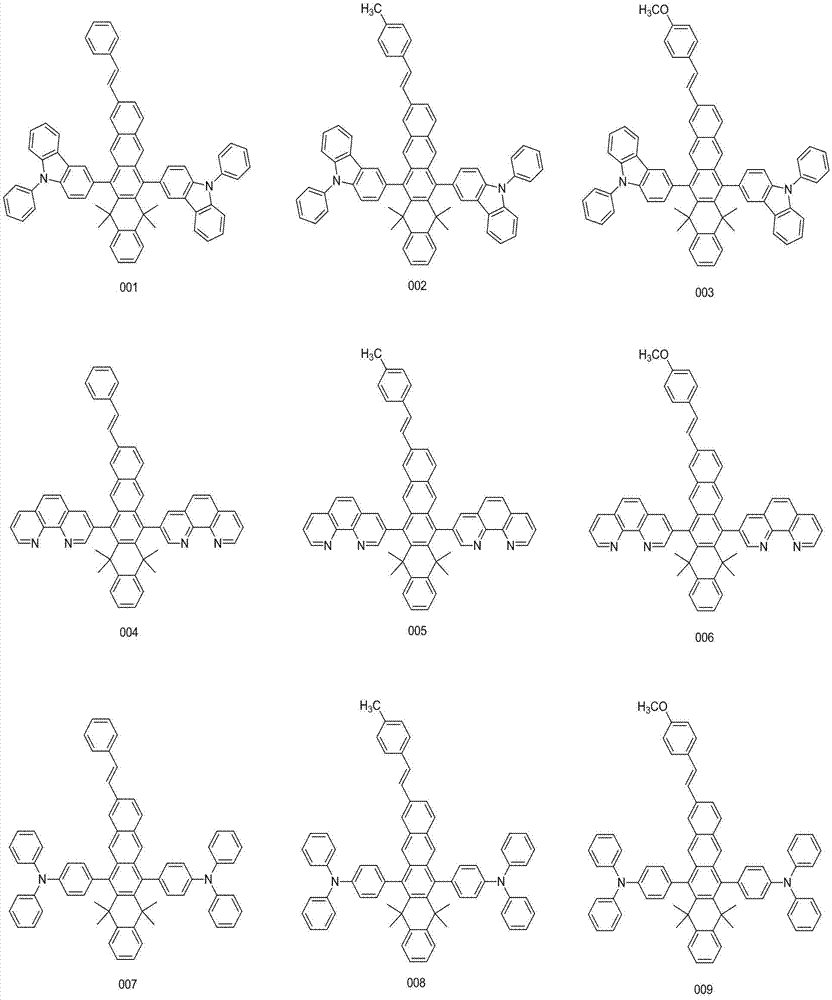

[0033] Example 1: Synthesis of compound 001

[0034] The specific synthesis route is shown in the following structural formula:

[0035]

[0036] (1) Under a nitrogen protection system, weigh 110mmol (49.3g) of 3-bromo-N-phenylcarbazole, add 300ml of freshly steamed tetrahydrofuran solution, and add dropwise n-butyllithium 7.19 at -78℃ g, react for 2 hours, then add dropwise 200ml containing 9-bromo-5,5,14,14-tetramethyl-4a,5,13a,14-dihydropentacene-6,13(4aH,13aH) two 50mmol (22.4g) of ketone in tetrahydrofuran solution, after dripping, under nitrogen protection, react at room temperature for 8 hours, add 100ml of 1M diluted hydrochloric acid, extract 3 times with 100ml of ether, separate, concentrate, use dichloromethane: Petroleum ether=1:3 recrystallized to obtain 41.2g of white intermediate N-phenyl-3-carbazolyl dihydropentacene alcohol derivatives.

[0037] (2) Take N-phenyl-3-carbazolyl dihydropentacene alcohol derivatives, add 300ml of concentrated sulfuric acid, and react a...

Embodiment 2

[0040] Example 2: Synthesis of Compound 004

[0041] The specific synthesis route is shown in the following structural formula:

[0042]

[0043] (1) Under nitrogen protection system, weigh 110mmol (28.5g) of 3-bromo-phenanthroline group, add 300ml of freshly steamed tetrahydrofuran solution, and add 7.19g of n-butyllithium dropwise at -78℃, reaction 6. Hours, then add dropwise 200ml containing 9-bromo-5,5,14,14-tetramethyl-4a,5,13a,14-dihydropentacene-6,13(4aH,13aH)dione 50mmol ( 22.4g) tetrahydrofuran solution, after dripping, under nitrogen protection, react at room temperature for 9 hours, add 100ml 1M dilute hydrochloric acid, extract 3 times with 100ml ether, separate and concentrate, use dichloromethane: petroleum ether = 1:3 recrystallization to obtain 39.4 g of a white intermediate 3-phenanthroline dihydropentacene alcohol derivative.

[0044] (2) Take 3-phenanthroline dihydropentacene alcohol derivatives, add 300ml of concentrated sulfuric acid, react at room temperature ...

Embodiment 3

[0047] Example 3: Synthesis of Compound 007

[0048] The specific synthesis route is shown in the following structural formula:

[0049]

[0050] (1) Under the protection of nitrogen, weigh 110mmol (35.5g) of 4-bromo-triarylamino group, add 300ml of freshly steamed tetrahydrofuran solution, and add 7.19g of n-butyllithium dropwise at -78℃ to react 4 hours, then add dropwise 200ml containing 9-bromo-5,5,14,14-tetramethyl-4a,5,13a,14-dihydropentacene-6,13(4aH,13aH)dione 50mmol ( 22.4g) tetrahydrofuran solution, after dripping, under nitrogen protection, react at room temperature for 9 hours, add 100ml of 1M dilute hydrochloric acid, extract 3 times with 100ml of ether, separate and concentrate, use dichloromethane: petroleum ether = 1:3 recrystallization to obtain 41.6 g of white intermediate triarylaminodihydropentacene alcohol derivatives.

[0051] (2) Take the triarylamine dihydropentacene alcohol derivatives, add 300ml of concentrated sulfuric acid, react at room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com