Method of taking bran as raw materials to prepare high-purity low-poly araboxylan and ferulic acid

An arabinoxylan, high-purity technology, applied in the field of comprehensive utilization of biomass, can solve the problems of affecting the extraction efficiency of active substances, easily destroying functional substances, low product purity, etc., so as to improve the utilization rate of raw materials and improve the functionality of products. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

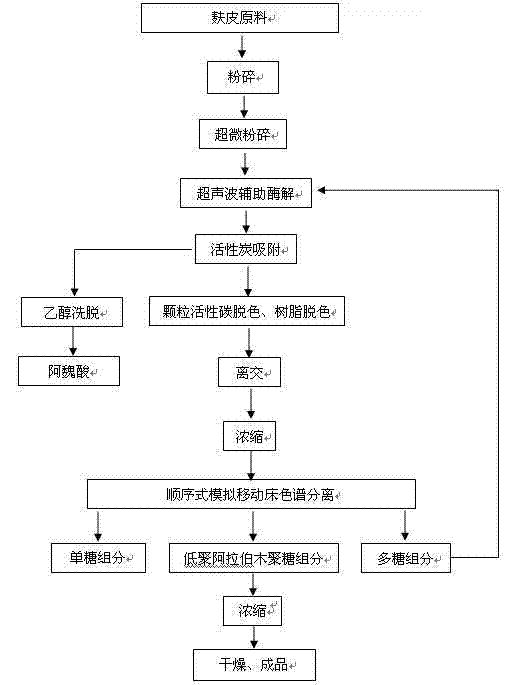

Image

Examples

Embodiment 1

[0025] (1) The bran is dried to a moisture content of less than 5%, firstly pulverized by a pulverizer, then passed through a 40-mesh sieve, and then pulverized by a mechanical ultrafine pulverizer to a size of 280 mesh;

[0026] (2) The superfine bran prepared in step (1) was prepared into a water suspension according to the mass ratio of 1:8, and 0.2 mL of high-temperature amylase was added to boil for 1 hour. After cooling to 60 ° C, the pH was adjusted to 8.5, and alkaline protease was added. Incubate at 50°C for 0.5h, then adjust the pH to 4.2, add glucoamylase to react for 0.5h, centrifuge at 3600 rpm for 20min, discard the supernatant, and wash the filter residue 3 times with hot distilled water;

[0027] (3) The filter residue after washing is prepared into a suspension with deionized water at a mass ratio of 1:6, and the enzyme preparation is added in an amount of 2% (on a dry basis) by adding xylanase and ferulic acid esterase in a mass ratio Composite enzyme prepara...

Embodiment 2

[0034] (1) The bran is dried to a moisture content of less than 5%, firstly crushed by a pulverizer, then passed through a 40-mesh sieve, and then crushed by a ball mill to 300 mesh;

[0035](2) The ultra-fine bran prepared in step (1) was prepared into a water suspension according to the mass ratio of 1:10, and 0.25 mL of high-temperature amylase was added to boil for 1.5 hours. After cooling to 60 ° C, the pH was adjusted to 8.8, and alkaline Incubate the protease at 50°C for 1 hour, then adjust the pH to 4.5, add glucoamylase to react for 0.5 hour, centrifuge at 3600 rpm for 20 minutes, discard the supernatant, and wash the filter residue 3 times with hot distilled water;

[0036] (3) The filter residue after washing was prepared into a suspension with deionized water at a mass ratio of 1:10, and the enzyme preparation was added at a mass ratio of 1.8% (on a dry basis) by adding xylanase and ferulic acid esterase 1:3.5 compound enzyme preparation, at the same time, use ultr...

Embodiment 3

[0043] (1) The bran is dried to a moisture content of less than 5%, firstly crushed by a pulverizer, then passed through a 40-mesh sieve, and pulverized by a jet mill to 300 mesh;

[0044] (2) The superfine bran prepared in step (1) was prepared into a water suspension according to the mass ratio of 1:8, and 0.22 mL of high-temperature amylase was added to boil for 1 hour. After cooling to 60°C, the pH was adjusted to 8.0, and alkaline protease was added. Incubate at 50°C for 0.5 h, then adjust the pH to 4.4, add glucoamylase for 1 h, centrifuge at 3600 rpm for 20 min, discard the supernatant, and wash the filter residue 4 times with hot distilled water;

[0045] (3) The filter residue after washing is prepared into a suspension with deionized water at a mass ratio of 1:9, and the enzyme preparation is added in an amount of 1.5% (on a dry basis) by adding xylanase and ferulic acid esterase in a mass ratio Composite enzyme preparation with a composition of 1:3, while using ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com