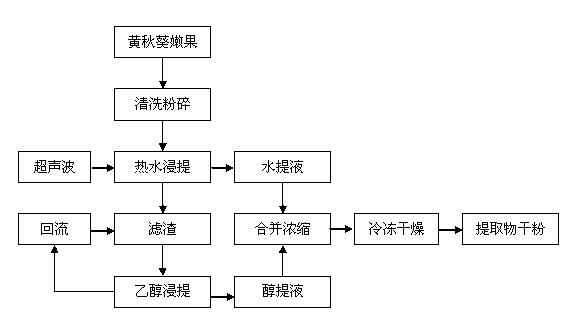

Preparation process of okra extractive dry powder

A preparation process and extract technology, which is applied in the field of preparation of okra extract dry powder, can solve the problems of nutrient loss, limited extraction efficiency, incomplete extraction, etc., achieve convenient transportation and use, save extraction time and solvent consumption, and extract high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking the tender fruit of 100kg okra as an example, the steps are as follows:

[0021] (1) raw material pretreatment, okra tender fruit removes impurities, rinses with clear water, transfers to tissue pulverizer to pulverize;

[0022] (2) Ultrasonic-assisted hot water extraction, the processed raw materials are transferred to the extraction equipment, and pure water is added according to the mass ratio of 1:6, the temperature is 55°C, and the power is 1800W. Ultrasonic-assisted extraction is 3.5h, and the extraction is completed and collected separately Extract and filter residue;

[0023] (3) Alcohol extraction of the filter residue, the filter residue obtained in step (2) is transferred to the extraction equipment, and 95% ethanol solution is added according to the mass ratio of 1:4 for reflux extraction for 3.5 hours, and the extract is fully collected;

[0024] (4) Concentrate in vacuo, combine the water extract and the alcohol extract obtained in the above two st...

Embodiment 2

[0028] Taking the tender fruit of 100kg okra as an example, the steps are as follows:

[0029] (1) raw material pretreatment, okra tender fruit removes impurities, rinses with clear water, transfers to tissue pulverizer to pulverize;

[0030] (2) Ultrasonic-assisted hot water extraction, the processed raw materials are transferred to the extraction equipment, and pure water is added according to the mass ratio of 1:10, the temperature is 60°C, and the power is 2000W, ultrasonic-assisted extraction is 5h, and the extraction is collected and extracted liquid and filter residue;

[0031] (3) Alcohol extraction of the filter residue, the filter residue obtained in step (2) is transferred to the extraction equipment, and 95% ethanol solution is added according to the mass ratio of 1:3 for reflux extraction for 2 hours, and the extract is fully collected;

[0032] (4) Concentrate in vacuo, combine the water extract and the alcohol extract obtained in the above two steps, reclaim th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com