Method for coating nano metal oxide catalyst precursor on ammonium perchlorate surface

A nano metal, ammonium perchlorate technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to simplify the dispersion process, accurate control, and autocatalytic effects obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

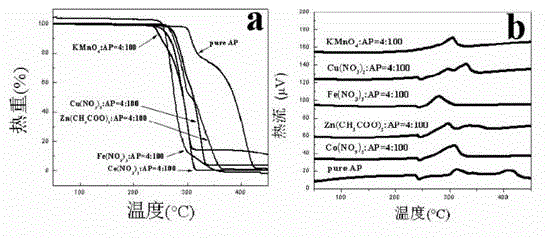

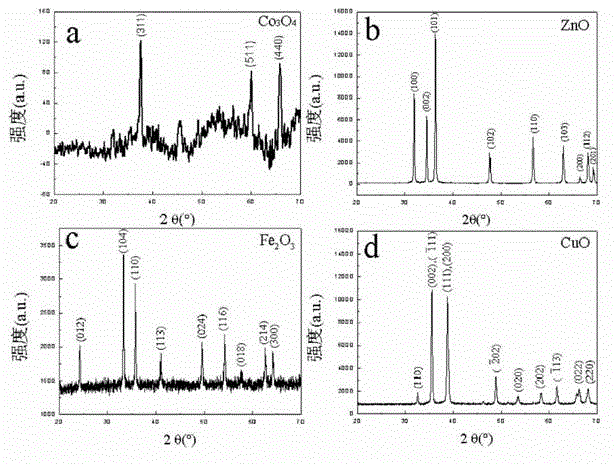

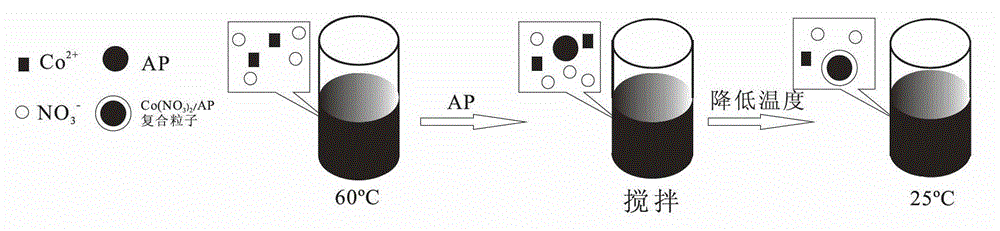

[0028] The preparation method provided by the invention comprises the following steps:

[0029] (1) The prepared mass is m AP The ammonium perchlorate (AP, Ammonium Perchlorate) is used for preparation, m AP is any value; the catalyst precursor (catalyst precursor) chemical formula is M a S b , with a mass of m cp , the relative molecular weight is M cp The chemical formula of the nanometer metal oxide catalyst (metal oxide nanocatalyst) that catalyst precursor thermal decomposition (before AP thermal decomposition) produces is M x o y , the relative molecular weight is M mon , the mass percent of nanometer metal oxide catalyst and AP is r (0.1%sol , with density ρ, at the solvent melting point (T m ) and boiling point (T b ) between two temperature points t 1 and t 2 ,T m 1 2 b (t 1 preferably room temperature), at t 1 At temperature, the solubility of the catalyst precursor in the solvent is m 1 , at t 2 At temperature, the solubility is m 2 , requiring (m 2...

Embodiment 1

[0035] AP / Co(NO 3 ) 2 Composite particles, m AP =2g, r=4%, the catalyst precursor is Co(NO 3 ) 2 , m cp =0.7752g, solvent is ethyl acetate, volume is V sol = 60mL, t 1 =25°C, t 2 = 60°C. The preparation steps are sequentially heating, dissolving, stirring, cooling, filtering and drying.

[0036] The AP used in the composite material is provided by Shanghai Reagent Co., Ltd., with an average particle size of 135 μm, and its morphology is shown in the attached figure 2 (a), (b) shows that the surface of uncoated AP particles is smooth.

[0037] In order to use a scanning electron microscope (FESEM FEI Sirion 200) to observe the coating effect of the obtained powder, its morphology is shown in the attached figure 2 As shown in (c) and (d), most of the surface of AP is coated, and the coating layer is dense and dendritic, with a length of about several microns. In order to analyze the elemental composition of the obtained powder, EDX analysis was performed on the comp...

Embodiment 2

[0042] AP / Co(NO 3 ) 2 Composite particles, m AP =2g, r=0.1%, the catalyst precursor is Co(NO 3 ) 2 , m cp =0.4924g, solvent is ethyl acetate, volume is V sol = 60mL, t 1 =25°C, t 2 = 60°C. The preparation steps are sequentially heating, dissolving, stirring, cooling, filtering and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com