Preparation method of jet fuel

A technology of jet fuel and hydrogen, which is applied in the field of preparation of jet fuel, can solve the problems of low yield of jet fuel, affecting the color of jet fuel, etc., and achieve the effect of stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

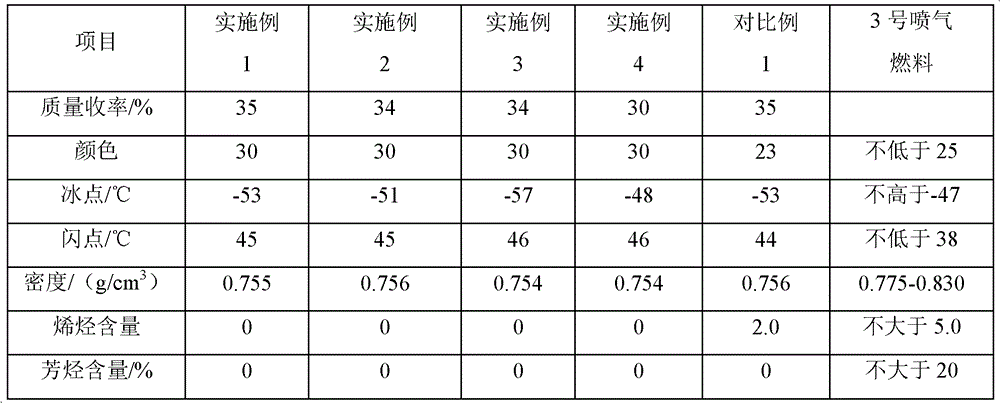

Examples

preparation Embodiment 1

[0044] Prepare the hydroisomerization catalyst according to the method for preparing the catalyst in Example 6 of CN1382526A: Weigh the catalyst C1 prepared in Example 1 in 40g of CN1382526A and 22g of solid alumina sol (the alumina content is 60% by weight, Zhejiang Province Alunite Comprehensive Produced by the research institute) mixed and extruded into a trilobal bar with a circumscribed circle diameter of 1.8 mm, dried at 120° C., calcined at 550° C. for 4 hours, and then filled with Pt (NH 3 ) 4 Cl 2 ·H 2 O aqueous solution 53.2g impregnation, 120 DEG C of oven dry, at 450 DEG C, flow is the hydrogen reduction of 800 milliliters / minute 4 hours, obtains catalyst A (containing crystallinity in A is the SAPO-11 molecular sieve 75% by weight of 77%, with element The platinum content is 0.3% by weight, and the rest is alumina).

preparation Embodiment 2

[0046] Prepare catalyst according to the method for embodiment 6 among CN1382526A, just replace the reference agent C1 prepared by embodiment 1 among CN1382526A with the reference agent B1 prepared in CN1382526A comparative example 1 to obtain catalyst B (containing crystallinity in B is 67% SAPO -11 molecular sieve 75% by weight, elemental platinum content 0.3% by weight, the balance is alumina).

Embodiment 1

[0048] (1) Under hydrodeoxygenation conditions, palm oil (sulfurizing agent dimethyl disulfide content is 0.02% by weight), H 2 Contact with hydrodeoxygenation catalyst RN-10, hydrodeoxygenation conditions include: pressure 5.0MPa, temperature 320°C, volume space velocity 1.0h -1 , the volume ratio of hydrogen to oil is 1000:1 (Nm 3 / m 3 );

[0049] (2) Under hydroisomerization conditions, the C13-C20 normal paraffins obtained after dehydration of the product after the aforementioned hydrodeoxygenation, H 2 Contact with hydroisomerization catalyst A, the hydroisomerization conditions include: pressure 5.0MPa, temperature 330°C, volume space velocity 1.0h -1 , the volume ratio of hydrogen to oil is 500:1 (Nm 3 / m 3 ).

[0050] (3) Under hydrorefining conditions, the product after the aforementioned hydroisomerization, H 2 Contact with hydrofinishing RLF-10W, hydrofinishing conditions include: temperature 150°C, pressure 5.0MPa, volumetric space velocity 2.0h -1 , the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com