Preparation method of electromagnetic shielding textile

An electromagnetic shielding and fabric technology, applied in the field of shielding fabric preparation, can solve the problems of poor shielding efficiency of electromagnetic shielding fabrics, high price of palladium as the activation center, environmental pollution of chemical plating process, etc., to improve shielding efficiency and increase binding force , Improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

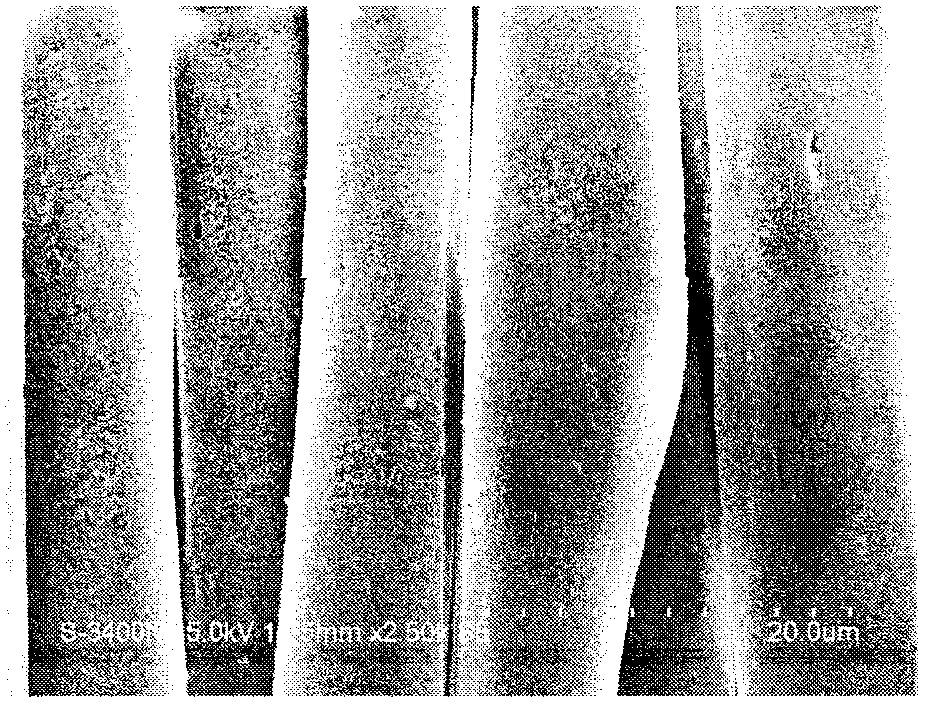

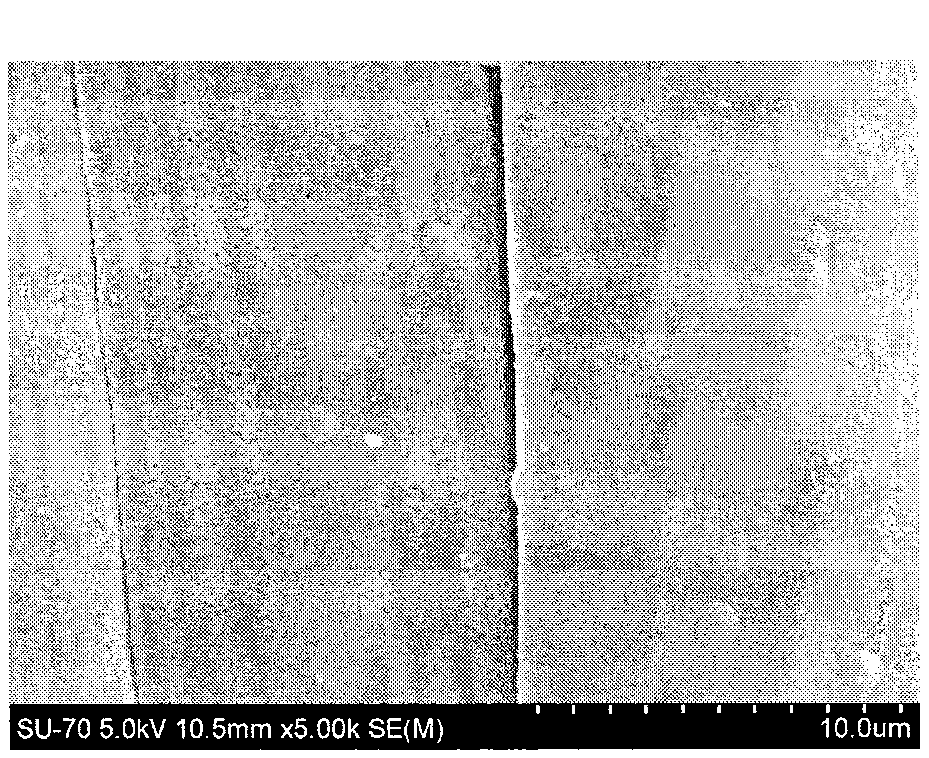

[0055] Use plain weave 260T polyester fabric as the substrate, the thickness is about 90 microns, and the surface density is about 56g / m 2 . A conductive polyester fabric with good shielding performance can be prepared according to the following conditions:

[0056] Cleaning: Wet the fabric with clean water first, and wash it again.

[0057] (1) Degreasing and coarsening: put the fabric into an aqueous sodium hydroxide solution for coarsening and degreasing, the concentration of NaOH in the solution is 40g / L, and the concentration of spandex refining agent CPA-2 is 1ml / L; the temperature is controlled at 80 ℃, take it out after 40 minutes of treatment, and rinse with clean water.

[0058] (2) Hydrogen plasma metallization silver plating: Dried polyester fabric after degreasing and roughening is dipped into a mixture of silver nitrate --- polyvinyl alcohol complex (complexing solution is silver nitrate and polyvinyl alcohol complex PVA complex configuration, in which AgNO 3...

Embodiment 2

[0067] Use plain weave 290T polyester fabric as the base material, the fabric material is 100% polyester, the thickness is about 100 microns, and the surface density is about 65g / m 2 . A conductive polyester fabric with good shielding performance can be prepared according to the following conditions:

[0068] Cleaning: Wet the fabric with clean water first, and wash it again.

[0069] (1) Degreasing and coarsening: the fabric is put into an aqueous sodium hydroxide solution for coarsening and degreasing, the concentration of NaOH in the solution is 50g / L, and the concentration of spandex refining agent CPA-2 is 3ml / L; the temperature is controlled at 90 ℃, take it out after 30 minutes, rinse it with clean water, and the weight loss rate reaches 8.4%.

[0070] (2) Hydrogen plasma metallization silver-plating: Dried polyester fabric after degreasing and roughening is impregnated with silver nitrate --- polyvinyl alcohol complex mixture (the complex solution is silver nitrate a...

Embodiment 3

[0079] Use polyester square cloth as the base material, the weight is 56g / m 2 , the thickness is 0.5mm. Conductive non-woven fabrics with good shielding performance can be prepared according to the following conditions:

[0080] Cleaning: Wet the fabric with clean water first, and wash it again.

[0081] (1) Degreasing and coarsening: the fabric is put into an aqueous solution of sodium hydroxide for coarsening and degreasing treatment. The concentration of NaOH in the solution is NaOH45g / L, and the concentration of spandex refining agent CPA-2 is 2ml / L; the temperature is controlled at 80 ℃, take it out after 40 minutes, and rinse with clean water.

[0082] (2) Hydrogen plasma metallization silver-plating: Dried polyester fabric after degreasing and roughening is impregnated with silver nitrate --- polyvinyl alcohol complex mixture (the complex solution is silver nitrate and PVA complex configuration Formed, where AgNO 3 250g / L for PVA, 250g / L for PVA), then dry the fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com