Preparation method of composite antibacterial softening agent

A compound antibacterial and softener technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems that composite fabric finishing agents have not been reported, and achieve the effect of reasonable raw materials and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

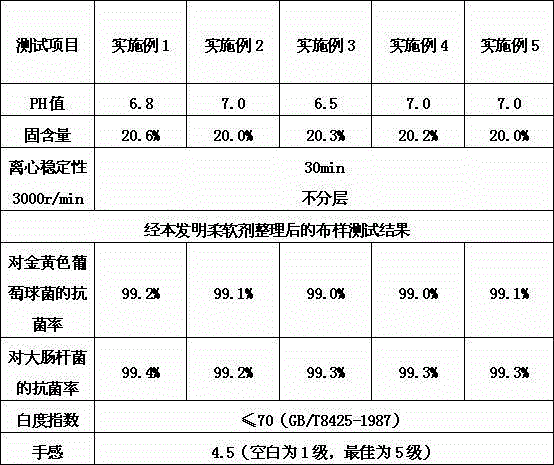

Examples

Embodiment 1

[0016] A) Prepare a mixed emulsion, mix 30 parts by weight of butyl acrylate and acrylic acid amide copolymer emulsion, 15 parts by weight of fatty acid polyoxyethylene ether, and 17 parts by weight of polyvinylpyrrolidone in 300 parts by weight of deionized water, stir evenly, and heat up to 35 ℃, at a speed of 1000r / min, add 200 parts by weight of N-βaminoethyl-γ-aminopropylmethyldimethoxysilane modified silicone oil, stir for 250min, then add 700 parts by weight of deionized water, at 1000r Continue to stir for 60min under the rotating speed of / min to obtain a mixed emulsion;

[0017] B) Prepare the finished compound antibacterial softener, add 2.0 parts by weight of silver nitrate and 0.6 parts by weight of ascorbic acid to the above mixed emulsion, and stir the mixed solution rapidly at 1000r / min for 180min at room temperature and normal pressure to obtain the low-yellowing composite softener of the present invention Antibacterial softener.

Embodiment 2

[0019] A) To prepare a mixed emulsion, mix 26 parts by weight of polymethacrylic acid emulsion, 12 parts by weight of sorbitan fatty acid, 2 parts by weight of xanthan gum, and 10 parts by weight of polyvinylpyrrolidone into 300 parts of deionized water, and stir evenly. Heat up to 30°C, add 50 parts by weight of γ-cyclohexylmethyldimethoxysilane modified silicone oil at 900r / min, stir for 260min, then add 700 parts by weight of deionized water, continue at 950r / min Stir for 55min to obtain a mixed emulsion;

[0020] B) Prepare the finished composite antibacterial softener, add 1.2 parts by weight of silver nitrate and 1.0 parts by weight of tartaric acid to the above mixed emulsion, and stir the mixed solution rapidly at 1100r / min for 190min at room temperature and normal pressure to obtain the low-yellowing composite softener of the present invention Antibacterial softener.

Embodiment 3

[0022] A) To prepare a mixed emulsion, mix 16 parts by weight of butyl acrylate and acrylic acid amide copolymer emulsion, 10 parts by weight of nonylphenol polyoxyethylene ether, and 14 parts by weight of sodium hydroxymethylcellulose into 300 parts of deionized water, and stir evenly. Raise the temperature to 40°C and add 100 parts by weight of N-βaminoethyl-γ-aminopropylmethyldimethoxysilane modified silicone oil, N-βaminoethyl-γ-aminopropyl 72 parts by weight of trimethoxysilane-modified silicone oil, stirred for 240 minutes, then added 700 parts by weight of deionized water, and continued to stir for 58 minutes at a speed of 1000 r / min to obtain a mixed emulsion;

[0023] B) Prepare the finished compound antibacterial softener, add 1.6 parts by weight of silver nitrate and 0.8 parts by weight of tannic acid to the above mixed emulsion, and stir the mixed solution rapidly at 900r / min for 185min at room temperature and normal pressure to obtain the low yellowing of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com