Gel type iodine ion adsorbent and preparation method and application thereof

An iodide ion and gel-type technology, which is applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem that the brine iodine resources are not fully developed and utilized, the selectivity of the adsorbent is not high, and the adsorbent Regeneration is difficult and other problems, to achieve the effect of simple and efficient elution regeneration, unlimited iodine content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

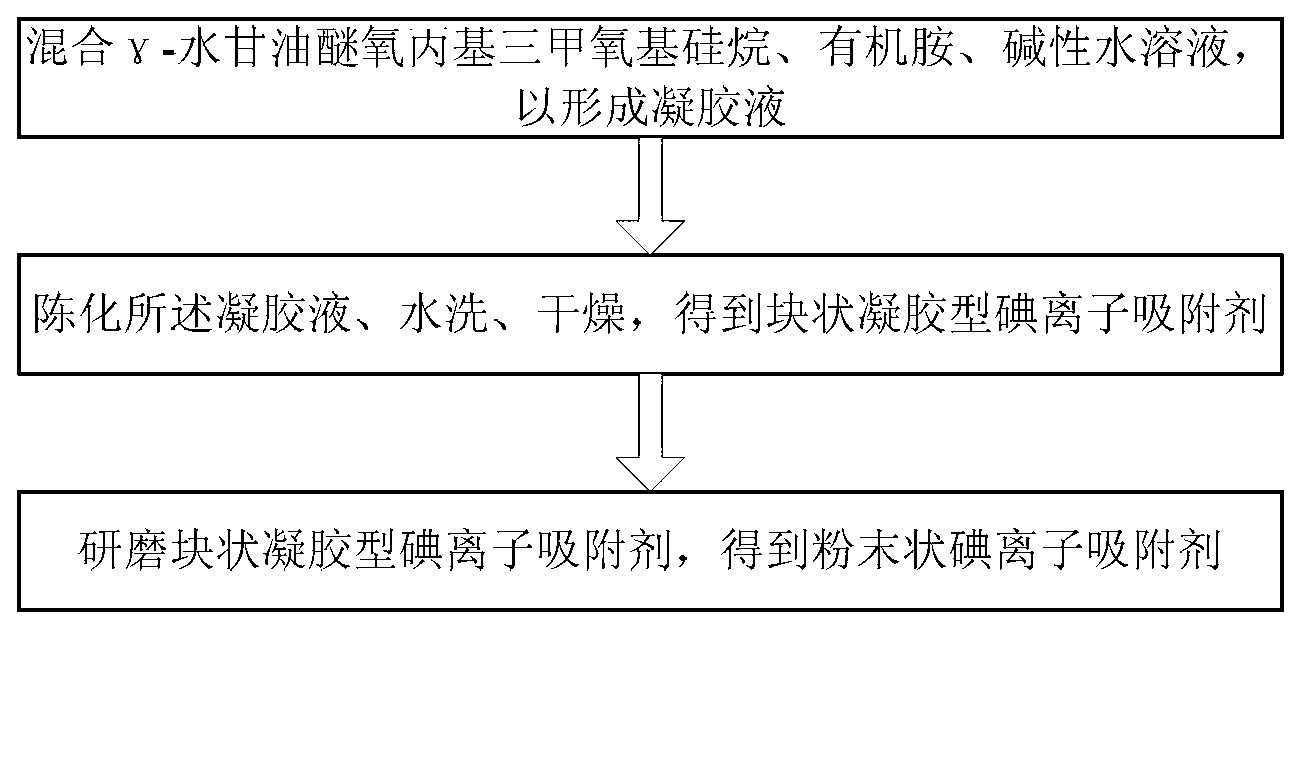

[0025] figure 1 A flow chart of a method for preparing a gel-type iodide ion adsorbent according to an embodiment of the present invention is shown. It can be seen from the figure that the preparation method mainly includes two steps: first, γ-glycidyl etheroxypropyltrimethoxysilane is mixed with organic amine and alkaline aqueous solution to form a gel solution. Afterwards, the gel liquid is aged, washed with water, and dried to obtain a block-shaped gel-type iodide ion adsorbent.

[0026] The gamma-glycidyl etheroxypropyl trimethoxysilane has simple gel forming conditions, and can form a mixed gel with uniform structure and stable properties meeting the requirements of the present invention with organic amines.

[0027] Organic amines can provide the main functional groups for the adsorption of iodide ions. Therefore, any organic amine containing amine group, imine group or tertiary amino group can be used in the present invention, common industrial organic amine includes ...

Embodiment 1

[0042] γ-glycidyl etheroxypropyltrimethoxysilane, C 8-10 Trialkylamine (N235) and 0.02mol / L sodium hydroxide aqueous solution were mixed according to the volume ratio of 1:1:1, and the stirring was continued for 0.5 hours to form a uniform gel; the resulting gel was aged for 24 hours, washed with water, Dry at 40°C for 24 hours to obtain block gel.

[0043] Grind and sieve, take an adsorbent with a particle size of 20-60 mesh, use the adsorbent to adsorb iodide ions in an acidic solution (pH=2) containing iodide ions, and the adsorption capacity is 427mg / g.

[0044] With 0.01mol / L Na 2 CO 3 The aqueous solution is eluted according to the solid-to-liquid ratio of 1g:0.1L, and the elution rate is 100%. After elution, it is washed to neutrality before adsorption, and the re-adsorption capacity of iodide ion is 427mg / g.

[0045] When 1mol / L NaCl coexists in the adsorption solution (molar ratio Cl - / I - =500), the adsorption capacity of iodine is 224mg / g.

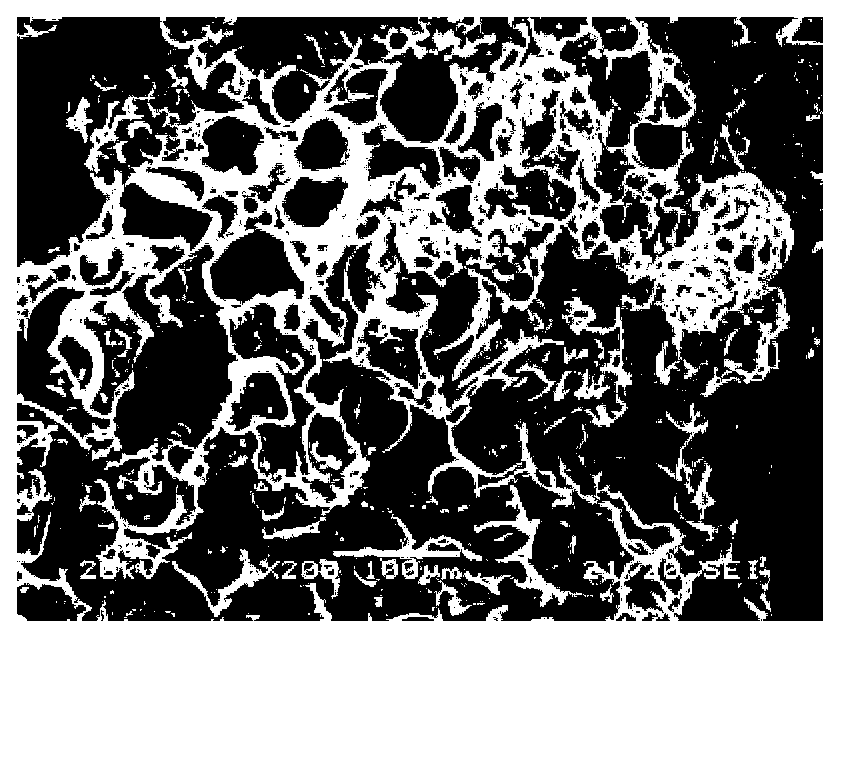

[0046] figure 2...

Embodiment 2

[0048] Mix γ-glycidyl etheroxypropyltrimethoxysilane, trioctylamine (N204), and 10mol / L ammonia solution in a volume ratio of 1:0.1:5, and keep stirring for 1 hour to form a uniform gel liquid; The resulting gel solution was aged for 5 hours, washed with water, and dried at 90° C. for 6 hours to obtain a block gel.

[0049] After grinding and sieving, the adsorbent is used to adsorb iodide ions in an acidic solution (pH=2), and the adsorption capacity is 352 mg / g.

[0050] With 0.005mol / L K 2 CO 3 The aqueous solution is eluted according to the solid-to-liquid ratio of 1g: 1L, and the elution rate is 100%. After elution, it is washed with water until it is neutral and then adsorbed. The re-adsorption capacity of iodide ion is 350mg / g.

[0051] When 1mol / L NaCl coexists in the adsorption solution (molar ratio Cl - / I - =500), the adsorption capacity of iodine is 190mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com