Special cotton fertilizer produced by using biochemical fulvic acid through melt granulation and production method of special fertilizer

A technology of fulvic acid cotton and special fertilizer, which is applied in the direction of application, fertilization device, fertilizer mixture, etc., to achieve the effect of large buds, high bud-setting rate, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

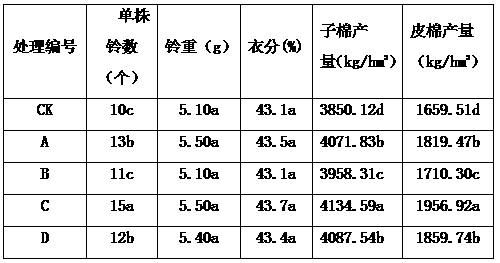

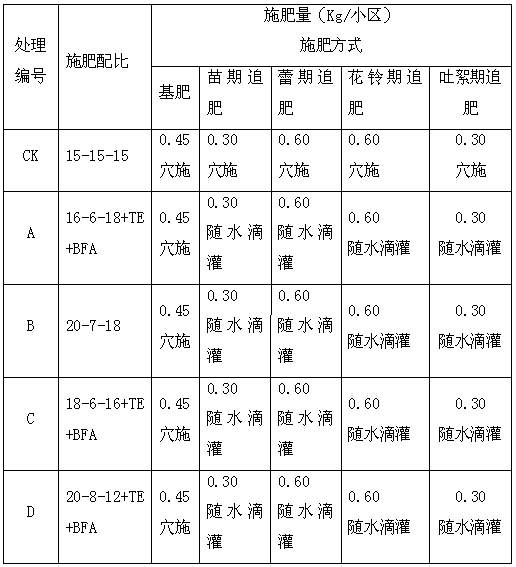

Examples

Embodiment 1

[0074] Raw materials: 500 parts of ammonium phosphate, 50 parts of potassium chloride, 50 parts of monoammonium phosphate, 290 parts of potassium sulfate, 60 parts of biochemical fulvic acid, 15 parts of EDTA chelated iron, 10 parts of EDTA chelated zinc, EDTA chelated manganese 8 parts, 16.6 parts of borax, and 0.4 parts of ammonium heptamolybdate.

[0075] The production method is as follows: Step 1: Melt 500 parts of ammonium nitrate at high temperature (160°C-170°C), put it into the buffer tank, pressurize it through the delivery pump, and pump it into the top mixer.

[0076] Step 2: Mix 50 parts of potassium chloride, 50 parts of monoammonium phosphate, 290 parts of potassium sulfate, 60 parts of biochemical fulvic acid, 15 parts of EDTA chelated iron, 10 parts of EDTA chelated zinc, 8 parts of EDTA chelated manganese, 15 parts 1 part of borax and 2 parts of ammonium heptamolybdate, after being metered, sent to the mixer and mixed evenly, sent to the top silo by bucket el...

Embodiment 2

[0080] Raw materials: 600 parts of ammonium phosphorus nitrate, 150 parts of potassium chloride, 80 parts of monoammonium phosphate, and 170 parts of potassium sulfate.

[0081] Production method is the same as implementation example 1.

[0082] The obtained product specification is N-P 2 o 5 -K 2 O(20-7-18), does not contain biochemical fulvic acid and trace elements.

Embodiment 3

[0084] Raw material: 540 parts of ammonium nitrate phosphorus, 100 parts of potassium chloride, 70 parts of monoammonium phosphate, 180 parts of potassium sulfate, 60 parts of biochemical fulvic acid, 15 parts of EDTA chelated iron, 10 parts of EDTA chelated zinc, EDTA chelated manganese 8 parts, 16.6 parts of borax, and 0.4 parts of ammonium heptamolybdate.

[0085] Production method is the same as implementation example 1.

[0086] The obtained product specification is N-P 2 o 5 -K 2 O (18-6-16), containing biochemical fulvic acid and trace elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com