High-efficiency simple synthetic method for delta-chlorobutyl ester

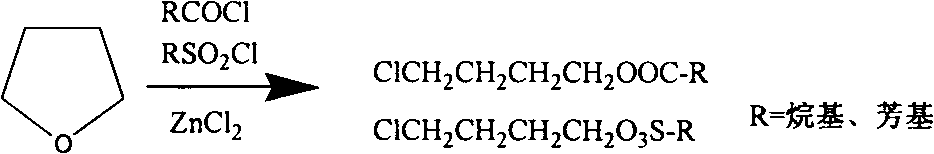

A technology of chlorobutyl ester and synthesis method, which is applied in the field of preparation of δ-chlorobutyl ester, and can solve the problems of cumbersome handling, waste of tetrahydrofuran, unfavorable industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the preparation of 4-chlorobutanol ethyl ester

[0014] Add 1 gram of anhydrous zinc chloride and 78.5 grams of acetyl chloride to a 250 ml three-necked bottle, add 72 grams of tetrahydrofuran dropwise under stirring, cool in an ice bath to keep the temperature below 30 degrees, keep warm for 1 hour after dropping, and distill under reduced pressure with a water pump to obtain 145 g of ethyl 4-chlorobutanol, yield 96%, purity 99.5%.

Embodiment 2

[0015] Embodiment 2: the preparation of 4-chlorobutanol chloroacetate

[0016] Add 1 gram of anhydrous zinc chloride and 113 grams of chloroacetyl chloride to a 250 ml three-necked bottle, add 72 grams of tetrahydrofuran dropwise at room temperature under stirring, keep it stable at 40 degrees during the dropping process, keep warm for 1 hour after the dropping, and reduce Pressure distillation yielded 166.6 g of 4-chlorobutanol chloroacetate with a yield of 90% and a purity of 99.2%.

Embodiment 3

[0017] Embodiment 3: the preparation of 4-chlorobutanol benzoate

[0018] Add 1 gram of anhydrous zinc chloride and 141 grams of benzoyl chloride to a 250 ml three-necked bottle, add 72 grams of tetrahydrofuran dropwise at room temperature under stirring, keep it stable below 40 degrees during the dropping process, keep warm for 2 hours after the dropping, and depressurize Distilled to obtain 200 g of 4-chlorobutanol benzoate with a yield of 94% and a purity of 99.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com