A kind of spray-free metal texture PMMA modified material and preparation method thereof

A metal texture and modified material technology, which is applied in the field of spray-free metal texture PMMA modified materials and its preparation, can solve the problems of poor processing performance, decreased toughness, and poor fluidity, and achieve excellent toughness and processing performance. Texture, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

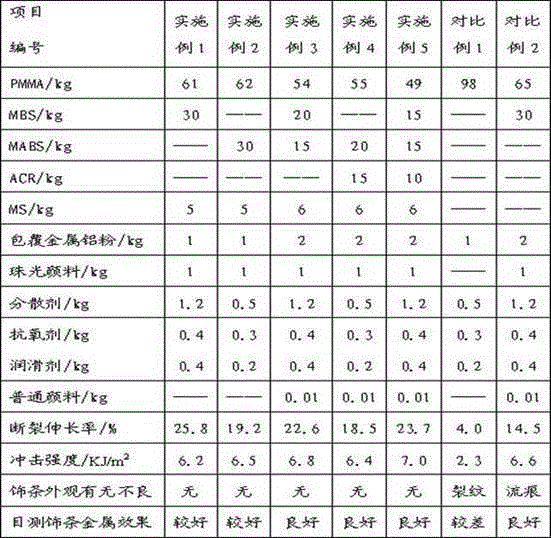

Examples

Embodiment 1

[0032] Add 61kg of PMMA, 30kg of MBS, 5kg of MS, 1kg of coated metal aluminum powder, 1kg of pearlescent pigment, 1.2kg of modified EBS, 0.2kg of antioxidant 1010, 0.2kg of antioxidant 168, and 0.4kg of ZnSt into the high-speed mixer , set the speed at 200r / min, mix for 5 minutes, after mixing evenly, accurately measure and feed with a screw feeder, knead and extrude in a twin-screw extruder, the screw length-to-diameter ratio is 40:1, Set the speed of the main machine to 300r / min, the temperature of the 1st-3rd stage of the extruder is 200°C, the 4th-7th stage is 210°C, and the 8th-10th stage is 220°C. After cooling and pelletizing, the product is obtained.

[0033] Note: the coated metal aluminum powder of this embodiment is SiO 2 Coated aluminum powder, the diameter of the aluminum powder is 60-100 μm, and the ratio of diameter to thickness is 40-80:1; the outer coating material of the pearlescent pigment is nano-sized TiO 2 , the same below.

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is: with PMMA 62kg, MABS 30kg, MS 5kg, coated metal aluminum powder 1kg, pearlescent pigment 1kg, modified EBS 0.5kg, antioxidant 1010 0.3 kg, ZnSt 0.2kg, add In the high-speed mixer, the set speed is 300r / min, and the mixture is mixed for 2 minutes. After the mixing is uniform, the screw feeder is used to accurately measure and feed the materials, and the twin-screw extruder is mixed and extruded. The screw length-to-diameter ratio is 40:1, set the speed of the main engine to 300r / min, the temperature of the 1st-3rd stage of the extruder is 210°C, the 4th-7th stage is 220°C, the 8th-10th stage is 230°C, after cooling and pelletizing, you can get product.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is: PMMA 54kg, MBS 20kg, MABS 15kg, MS 6kg, coated metal aluminum powder 2kg, pearlescent pigment 1kg, modified EBS 1.2kg, antioxidant 1076 0.2 kg, antioxidant Add 0.2kg of agent 245, 0.4kg of ZnSt, and 0.01kg of phthalocyanine blue pigment into a high-speed mixer, set the speed at 200r / min, and mix for 5 minutes. After mixing evenly, use a screw feeder to accurately measure and feed. Mixing and extrusion in a twin-screw extruder, the length-to-diameter ratio of the screw is 40:1, the speed of the main engine is set to 350r / min, the temperature of the 1-3 section of the extruder is 200°C, the 4-7 section is 210°C, 8 The -10 section is 220°C, and after cooling and pelletizing, the product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com