Method for cold-spraying preparation of ZrO2-CeO2 ceramic coating

A ceramic coating and cold spraying technology, which is applied in the direction of pressure inorganic powder coating, etc., can solve difficult problems such as coating structure and morphology, coating cracking and damage, and degradation of matrix mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 powder sol-gel coating process

[0052] Weigh Ce(NO3)2.6H2O and polyethylene glycol 400 at a molar ratio of 1:2; put the polyethylene glycol into a beaker, put it in a constant temperature water bath at 80°C, and fully dissolve the cerium nitrate into the mixture by stirring. Polyethylene glycol 400; keep stirring until a transparent colloid is formed; in order to control the Zr: Ce in the coating powder to be 10:1 molar ratio, weigh a quantitative amount of ZrO 2 Mixed into the gelatin formed in the above steps for continuous stirring to form a well-mixed gel;

[0053] Clean the gel with absolute ethanol at room temperature and filter; put the rubber cake in a muffle furnace and bake at 500°C for 1.5 hours to obtain CeO 2 Coated ZrO 2 Powder; cooled to room temperature and then milled in a corundum jar to obtain a yellow powder.

Embodiment 2

[0054] Embodiment 2 The whole process of coating preparation

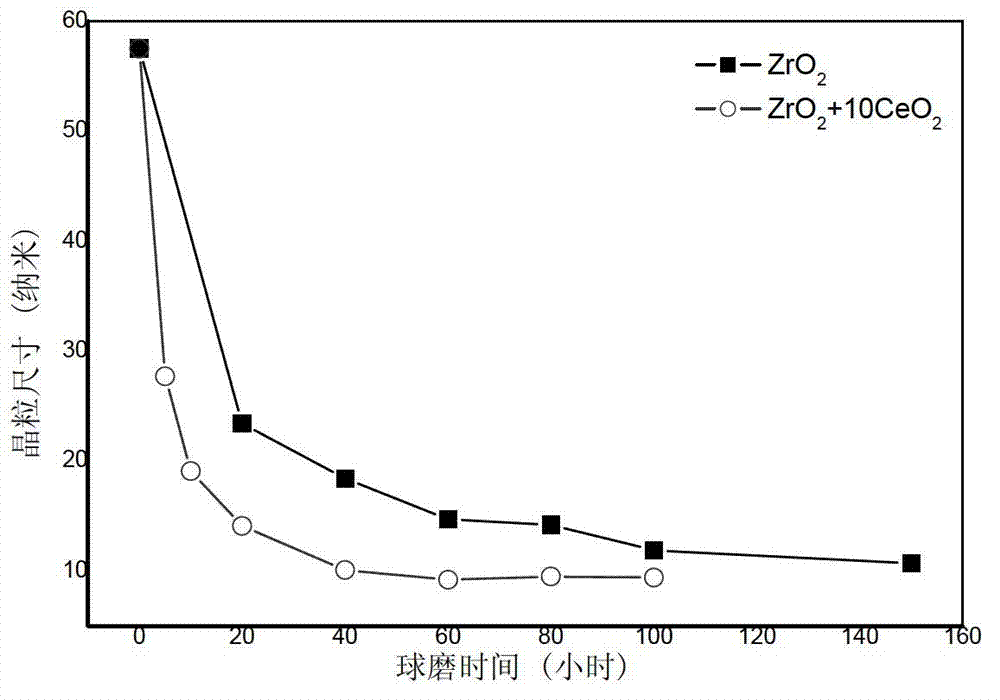

[0055] (1) Powder ball milling treatment

[0056] Grinding balls: 30 large (10mm) + 60 medium (8mm) + 90 small (5mm) balls

[0057] Powder: 10mol.%CeO 2 +ZrO 2 Powder 20g (initial ZrO 2 Powder coated CeO by sol-gel process 2 )

[0058] The ball milling speed was 200r / min, and after ball milling for 20 hours, the XRD detection powder grain size was 11nm, and the amorphous component content was 16%.

[0059] Spray granulation: temperature 225°C, sphericity 85%, particle size D90=18μm.

[0060] (2) Cold spray deposition process

[0061] Working gas: Nitrogen (N 2 ), gas temperature: 550°C, pressure: 29 atmospheres (calculated powder particle velocity is 639m / s), powder feeding speed: 14g / min, powder preheating temperature: 350°C, spraying distance: 30mm, spray gun sweeping speed : 100mm / s, two sprays.

[0062]Obtained coating: deposition efficiency 45%; porosity 1.1%; thickness 38 μm, tensile bonding strengt...

Embodiment 3

[0064] (1) Powder ball milling treatment

[0065] Grinding balls: 30 large (10mm) + 60 medium (8mm) + 90 small (5mm) balls;

[0066] Powder: 10mol.%CeO 2 +ZrO 2 Powder 20g (initial ZrO 2 Powder coated CeO by sol-gel process 2 );

[0067] The ball milling speed was 180r / min, and after 20 hours of ball milling, the XRD detection powder grain size was 11nm, and the amorphous component content was 16%.

[0068] Spray granulation: air inlet temperature 225°C, sphericity 85%, particle size D90=18μm.

[0069] (2) Cold spray deposition process

[0070] Working gas: helium (He), gas temperature: 350°C, pressure: 15 atmospheres (calculated powder particle velocity is 781m / s), powder feeding speed: 10g / min, powder preheating temperature: 300°C, spraying Distance: 30mm, spray gun sweeping speed: 150mm / s, two sprays.

[0071] Obtained coating: deposition efficiency 60%, porosity 0.9%, thickness 40μm, bonding strength 54MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com