Electrode assembly of low-temperature plasma generator

A low-temperature plasma and electrode assembly technology, applied in the direction of plasma, electrical components, etc., can solve the problems of large space electromagnetic radiation, low energy conversion efficiency, complex processing technology, etc., achieve soft glow discharge, low cost, and suppress electromagnetic radiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

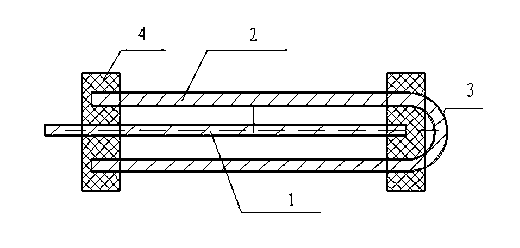

[0015] This embodiment is a low-temperature plasma generator electrode assembly with a linear structure, and its structure is as follows: figure 1 shown.

[0016] In this embodiment, the positive electrode 1 and the negative electrode 2 are both made of ordinary red copper enameled wire, the outer surface of the electrode is covered with a quartz glass sleeve as the insulating medium layer 3, and the clamping insulating bracket 4 is made of polytetrafluoroethylene molded. The low-temperature plasma generator made with this electrode is used in air sterilization and purification equipment, and the effect of one set is far more than four sets of corona plasma generators from Plasma-air Company of the United States, while the cost is only one-fifth of it.

[0017] This embodiment can be widely applied to air sterilization and purification equipment in hospital operating rooms.

Embodiment 2

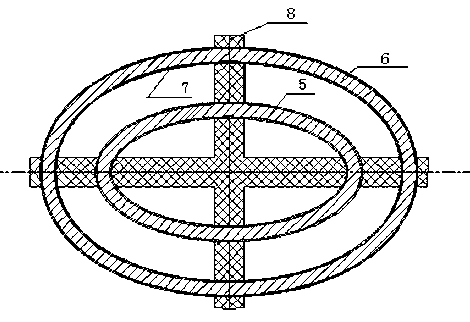

[0019] This embodiment is a low-temperature plasma generator electrode assembly with an elliptical structure, and its structure is as follows: figure 2 shown.

[0020] In this embodiment, the positive electrode 5 and the negative electrode 6 are both made of alloy tungsten wire, the outer surface of the electrode insulating medium layer 7 is made by integral sintering of coated alumina ceramics, and the clamping insulating support 8 is made of alumina ceramics by molding and calcining.

[0021] The low-temperature plasma generator manufactured with the electrode of this embodiment is used in a household fresh-keeping degrader, and its plasma volume density basically meets the product function requirements, while the energy consumption is much lower than that of Chinese patent 201210021690.X.

[0022] The electrode of this embodiment can be applied to a fresh-keeping degrader for keeping vegetables and fruits fresh at home and degrading pesticide residues on the surface.

Embodiment 3

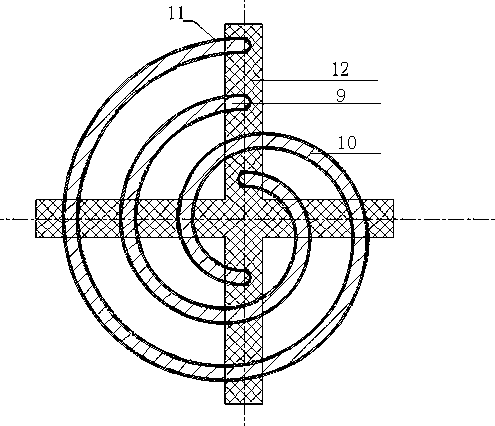

[0024] This embodiment is a low-temperature plasma generator electrode assembly with a spiral structure, and its structure is as follows image 3 shown.

[0025] The positive electrode 9 and the negative electrode 10 of this embodiment are made of stainless steel wire, and the insulating medium layer 11 on the outer surface is a high-purity polytetrafluoroethylene sleeve that is sheathed on the periphery of the electrode, and the clamping insulating support 12 is molded and calcined by alumina ceramics. production. The low-temperature plasma generator made of this electrode is used in the sterilization and fresh-keeping system or the disinfection and purification system, which can produce greater use effect with less energy consumption. According to the test, every 1000m 3 The energy consumption of a day is only about 1 kilowatt-hour, and the treated space is almost free of pathogenic bacteria, harmful gases and particles.

[0026] The spiral electrode given in this example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com