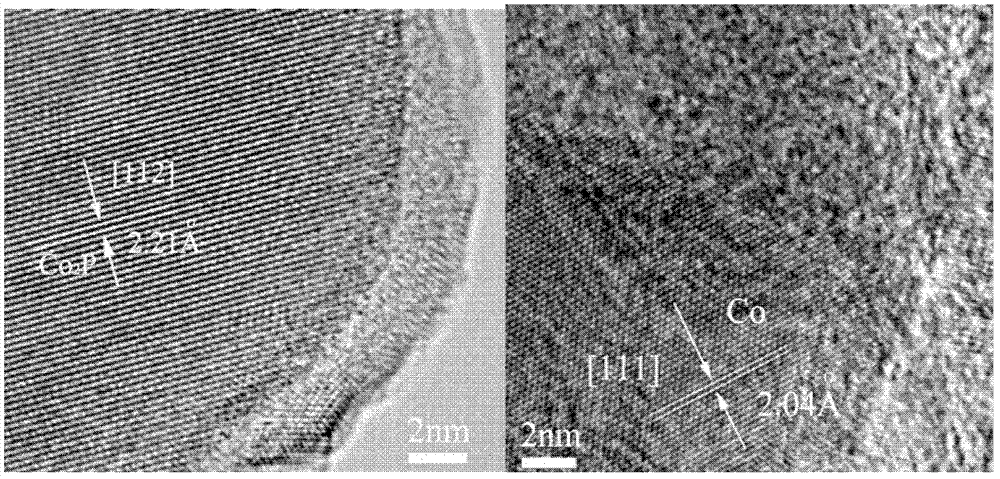

Cobalt phosphide catalyst for preparing 3-pentanone and propanal from hydrogen, carbon monoxide and ethylene

A carbon monoxide and catalyst technology, applied in the direction of carbon monoxide reaction preparation, physical/chemical process catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The catalyst of Example 1 is 15% Co-0.66% P / coconut shell carbon (Co / P=12 molar ratio). Weigh 10.0 grams of coconut shell charcoal (20-40 mesh, BET specific surface area: 1135m 2 / g, the average pore size is 21nm), the configuration 8ml contains 7.80 grams of Co(NO 3 ) 2 .6H 2 O and 0.3 g (NH 4 ) 2 HPO 4 aqueous solution, drop about 2ml of concentrated HNO 3 , heat to dissolve, impregnate the coconut shell charcoal carrier with this aqueous solution, dry in a water bath at 60°C, and dry in an oven at 80°C for 8 hours. At this time, the weight of the dried sample was about 18.45 grams. The prepared product is the precursor of the 15%Co-0.66%P / coconut shell carbon catalyst.

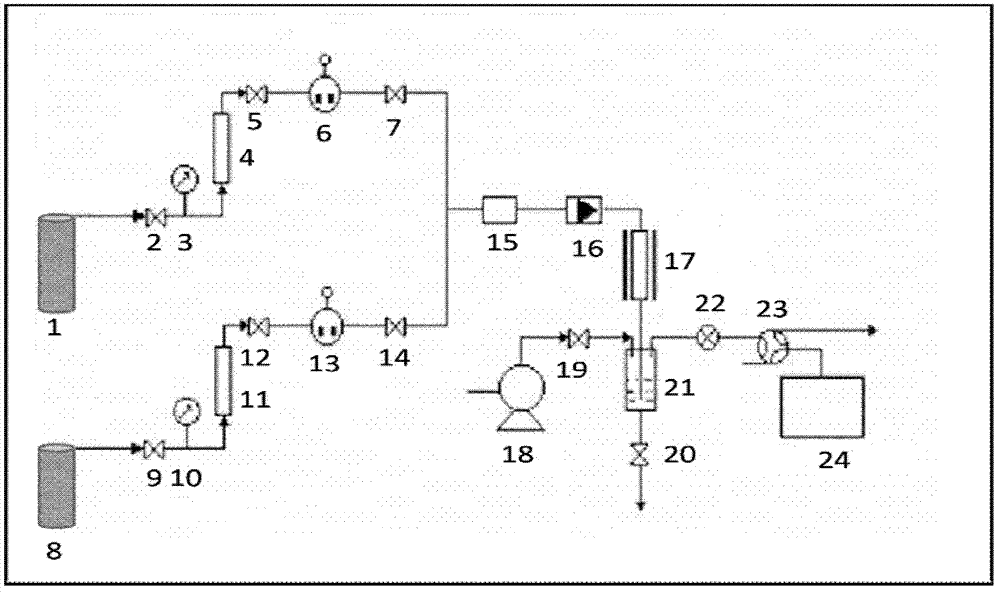

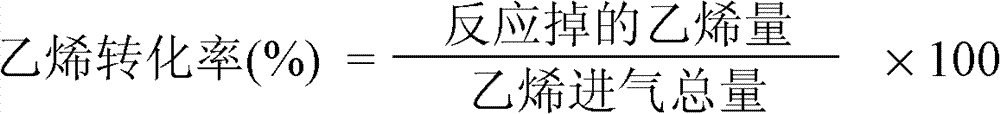

[0023] Before the precursor of the above-mentioned catalyst is used, take 5ml (3.4 grams) of the above-mentioned catalyst and place it in the inner diameter of φ10, and the length is the middle section of a stainless steel reactor of 30 cm, and both ends are filled with 20-40 mesh quartz sand...

Embodiment 2

[0025] The catalyzer of embodiment 2 is 15%Co-0.66%P / almond kernel charcoal (Co / P=12 molar ratio). In addition to using apricot charcoal (BET specific surface area: 1070m 2 / g, the average pore diameter is 25nm), and all the other preparation steps are the same as in Example 1.

Embodiment 3

[0027] The catalyst of Example 3 is 15% Co-0.66% P / carbon nanotube (Co / P=12 molar ratio). In addition to the use of carbon nanotubes (BET specific surface area: 254m 2 / g, the average pore diameter is 7.5nm), and all the other preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com