Preparation and applications of novel alkyl cage silsesquioxane nanometer hybrid

A technology of silsesquioxane and nano-hybrid, which is applied in the directions of organic silicon compounds, medical preparations with inactive ingredients, and pharmaceutical formulations, etc. The problem of unsatisfactory drug dosage, etc., achieves the effect of favorable loading rate, easy product preparation, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

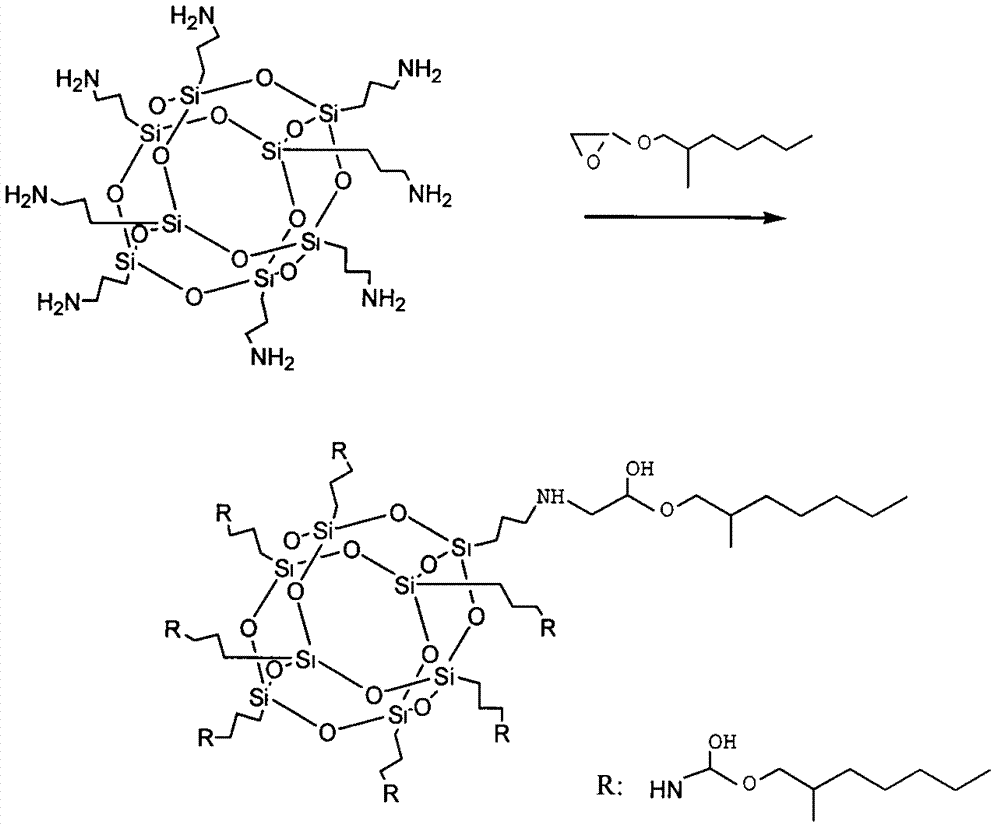

[0017] Embodiment 1 has cage type polysilsesquioxane (POSS-NH 2 ) preparation:

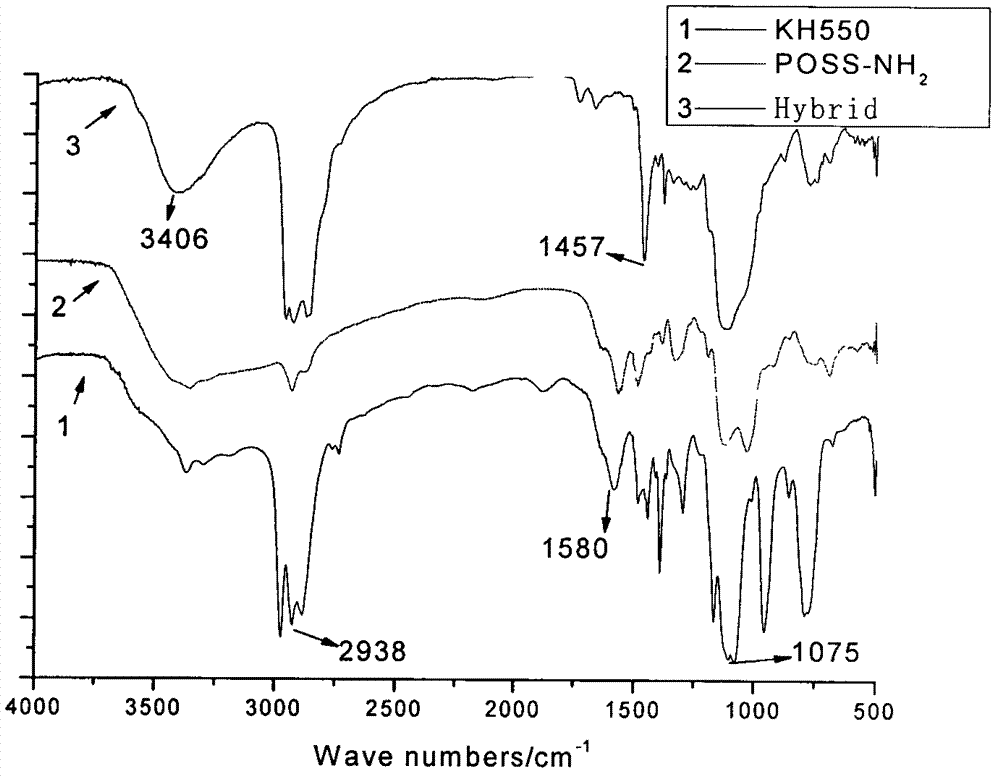

[0018] Put the monomer γ-aminopropyltriethoxysilane, tetraethoxyammonium hydroxide (20%), water, and n-propanol into a 500ml round-bottomed flask in a certain proportion, and magnetically stir the reaction at 50°C After 24 hours, a viscous liquid was obtained. The reaction product was distilled under reduced pressure to remove impurities such as n-propanol and water as much as possible, and extracted with ethanol to remove unreacted monomers, then the product was added to THF, and THF was used as a precipitant to further treat the product , and finally the product was further purified by vacuum drying. The product see diagram 2-1 .

Embodiment 2

[0019] The preparation of embodiment 2 nano-hybrids:

[0020] The POSS-NH obtained above 2 , octyl glycidyl ether, add a certain amount of ethanol, and react at 50°C for 24h. After the reaction, a layered product is obtained, and the lower oily viscous liquid is separated, washed with deionized water and a small amount of ethanol, and dried in vacuum for 24h. A pale yellow transparent viscous liquid was obtained.

Embodiment 3

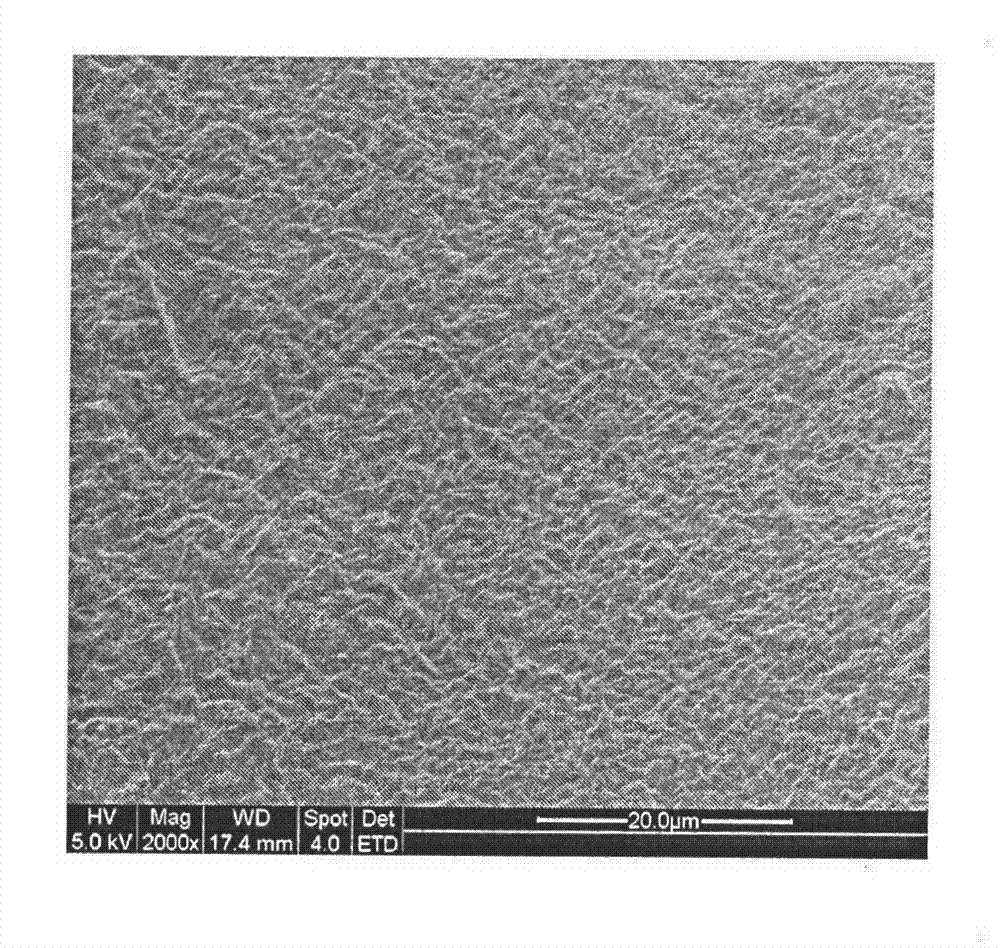

[0021] Example 3 Hybrid hydrogel xerogel sample preparation:

[0022] Prepare six parts with a mass fraction of 1% sodium alginate solution and a mass fraction of 3% calcium chloride solution, and take the mass ratio of the hybrid to sodium alginate as 0:1, 0.2:1, 0.4:1, 0.6:1, The 0.8:1, 1:1 hybrids were dissolved in a small amount of ethanol, and the sodium alginate solution and the hybrid ethanol solution were fully blended under the condition of high-speed mechanical stirring. Then, each group of sodium alginate solutions was dropped into the magnetic In the stirring calcium chloride solution, the gel particles were obtained, aged for 3 hours, filtered, washed and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com