Preparation method of hydroxyapatite/polylactic acid composite material

A technology of hydroxyapatite and composite materials, which is applied in the field of preparation of hydroxyapatite/polylactic acid composite materials, can solve the problems of insufficient mechanical properties, poor fatigue resistance, and small flexural modulus of hydroxyapatite, and achieve Short cycle time, excellent performance, and the effect of increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

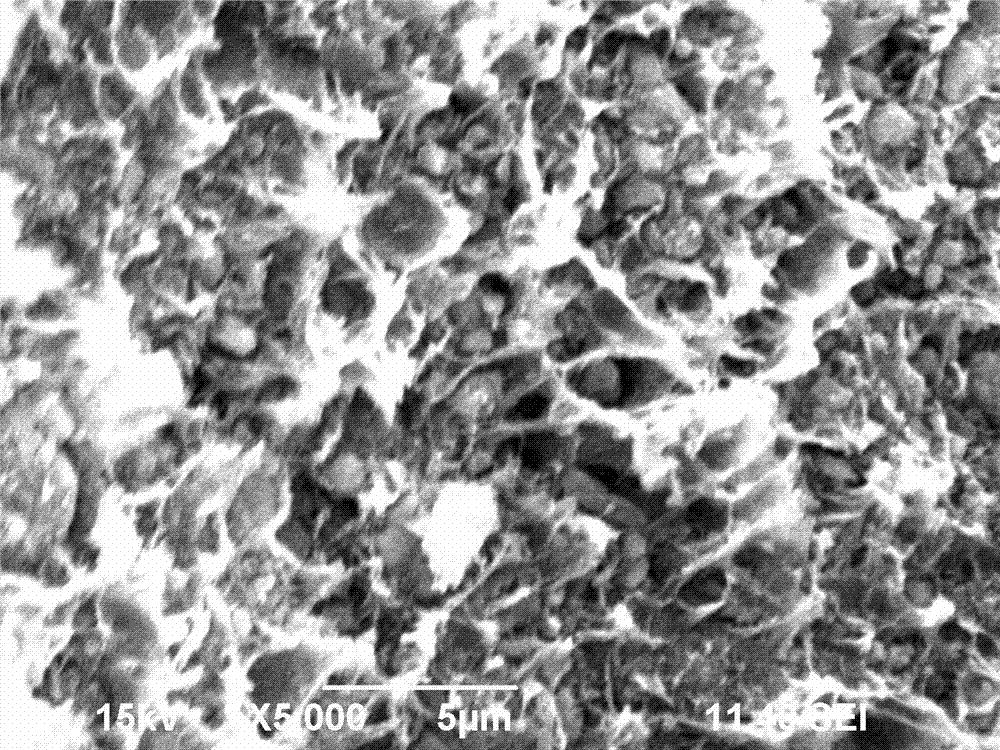

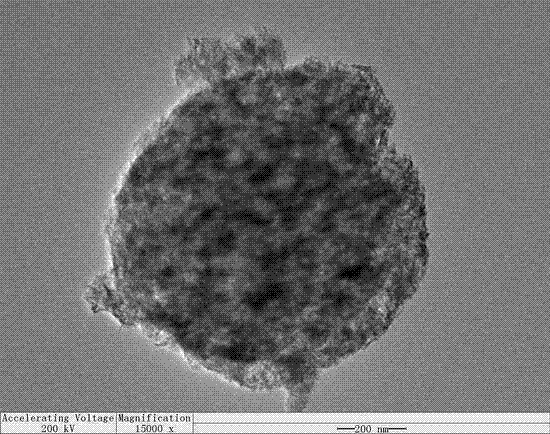

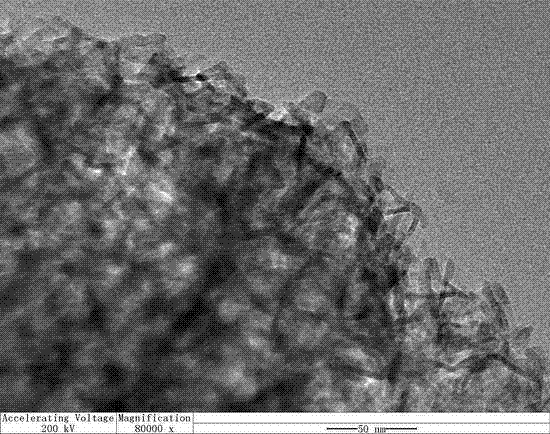

Image

Examples

Embodiment 1

[0019] First, solution configuration, 14 g of calcium nitrate tetrahydrate, 9 g of dipotassium hydrogen phosphate trihydrate, and 4 g of sodium hydroxide were respectively dissolved in 10 ml of primary water to prepare solutions for use. Take 10 ml of dipotassium hydrogen phosphate solution and add it to a 50 ml beaker, then add 3 ml of sodium hydroxide solution into the beaker, mix well and seal it for later use. Add 50 g of polylactic acid, 25 g of dioctyl sodium sulfosuccinate and 5 g of n-propanol to 500 ml of dichloromethane to form a polylactic acid solution, and seal it for later use.

[0020] Secondly, the preparation of calcium nitrate emulsion (referred to as emulsion 1) and the mixed emulsion of dipotassium hydrogen phosphate and sodium hydroxide (referred to as emulsion 2), and the process of preparing hydroxyapatite. Take 6.65 ml of calcium nitrate solution and add it to 75 ml of the previously prepared polylactic acid solution at a uniform rate, and mix evenly to...

Embodiment 2

[0024] First, solution configuration, 14 g of calcium nitrate tetrahydrate, 9 g of dipotassium hydrogen phosphate trihydrate, and 4 g of sodium hydroxide were respectively dissolved in 10 ml of primary water to prepare solutions for use. Take 10 ml of dipotassium hydrogen phosphate solution and add it to a 50 ml beaker, then add 3 ml of sodium hydroxide solution into the beaker, mix well and seal it for later use. Take 100 g of polylactic acid, 20 g of Tween 80 and 1 g of n-butanol and add them to 1000 ml of chloroform respectively to make a polylactic acid solution, and seal it for later use.

[0025] Secondly, the preparation of calcium nitrate emulsion (referred to as emulsion 1) and the mixed emulsion of dipotassium hydrogen phosphate and sodium hydroxide (referred to as emulsion 2), and the process of preparing hydroxyapatite. Take 6.65 ml of calcium nitrate solution and add it to 75 ml of the previously prepared polylactic acid solution at a uniform rate, and mix evenly ...

Embodiment 3

[0028] First, solution configuration, 14 g of calcium nitrate tetrahydrate, 9 g of dipotassium hydrogen phosphate trihydrate, and 4 g of sodium hydroxide were respectively dissolved in 10 ml of primary water to prepare solutions for use. Take 10 ml of dipotassium hydrogen phosphate solution and add it to a 50 ml beaker, then add 3 ml of sodium hydroxide solution into the beaker, mix well and seal it for later use. Take 55.2 g of polylactic acid, 10.6 g of sorbitan monostearate and 1 g of n-heptanol and add them to 552 ml of tetrahydrofuran respectively to make a polylactic acid solution, seal it for later use.

[0029] Secondly, the preparation of calcium nitrate emulsion (referred to as emulsion 1) and the mixed emulsion of dipotassium hydrogen phosphate and sodium hydroxide (referred to as emulsion 2), and the process of preparing hydroxyapatite. Take 6.65 ml of calcium nitrate solution and add it to 75 ml of the previously prepared polylactic acid solution at a uniform rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com