Internal-heating continuous type biochar equipment

A complete set of equipment and biochar technology, which is applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of poor feeding of biomass raw materials, insufficient carbonization, and recycle of combustible gas, so as to facilitate the carbonization reaction, The effect of reducing operating costs and preventing gas ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

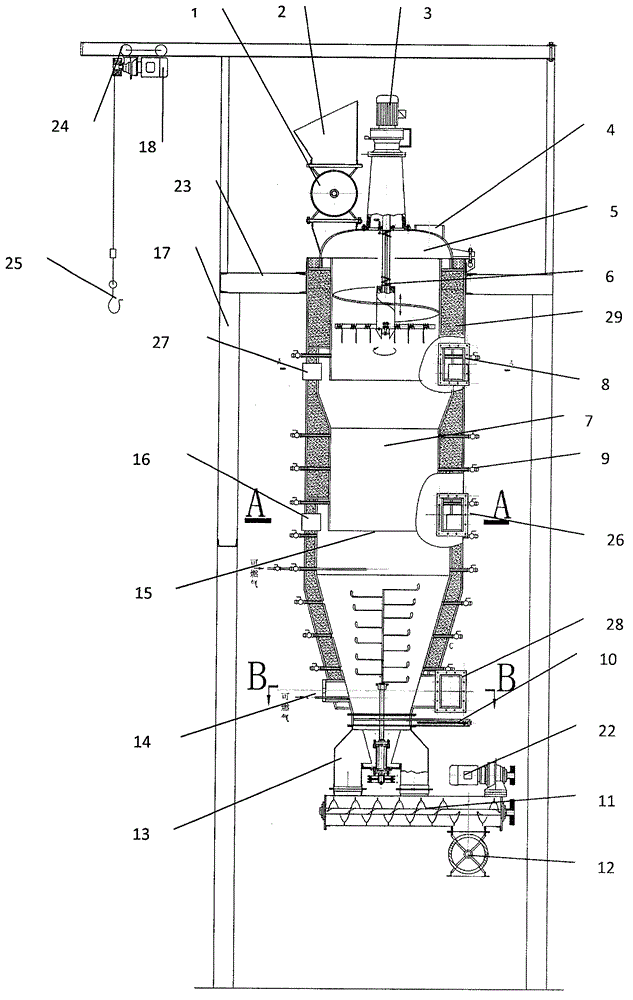

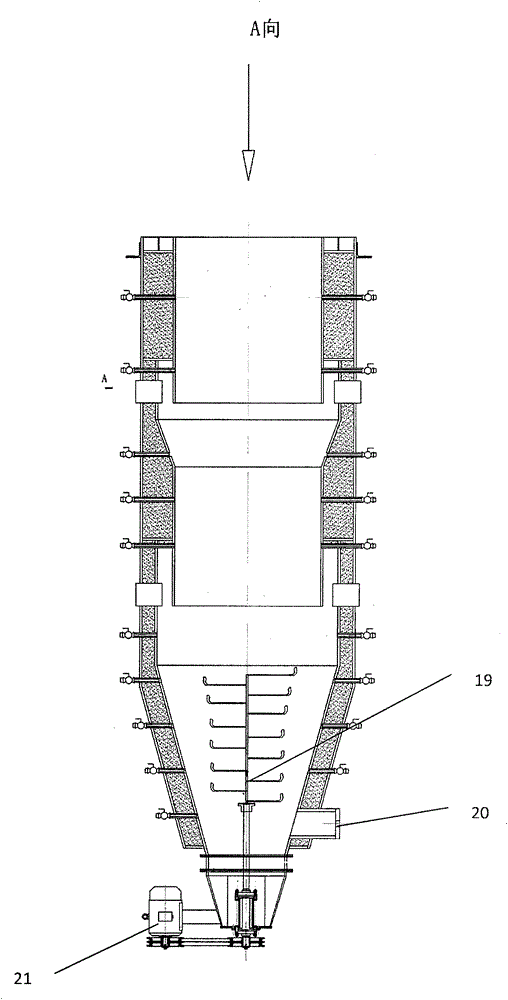

[0038] Embodiment: Adopt biomass briquette fuel to produce biochar

[0039] The internal heating continuous biochar complete set of equipment of the present invention is used to produce biochar, and the raw material is biomass briquette fuel with a diameter of 8mm and a length of about 20-30mm. After drying, the biomass briquette fuel weighs about 1 ton and is lifted to the top of the operation platform by a crane through a hook, then introduced into the feeding hopper, and fed into the feeding air locker. When the material is full of the hopper, slowly open the feeding air lock The material is conveyed into the carbonization furnace body through an active compactor, and is gradually compacted during the conveying process. Because the biomass carries a small amount of air, the resistance rod is ignited at this time, and part of the biomass is ignited in the furnace to increase the temperature in the furnace. The air volume is controlled through the air inlet and outlet, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com