Impedance type nickel film heatmeter based on laser etching method and manufacturing method thereof

A technology of laser etching method and manufacturing method, which is applied in the field of X-ray detection, can solve problems such as complicated manufacturing process, easily distorted patterns, chemical hazards, etc., and achieve the advantages of overcoming complicated manufacturing process, improving component performance and manufacturing process, and being easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

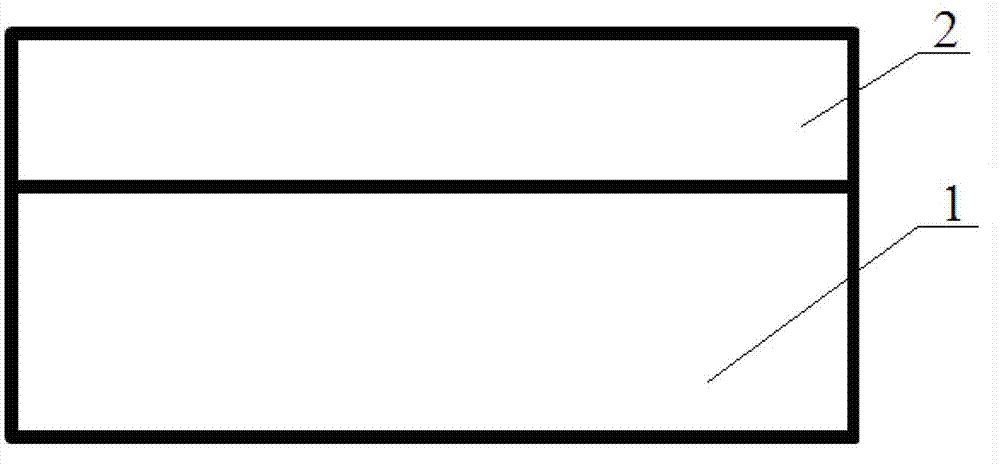

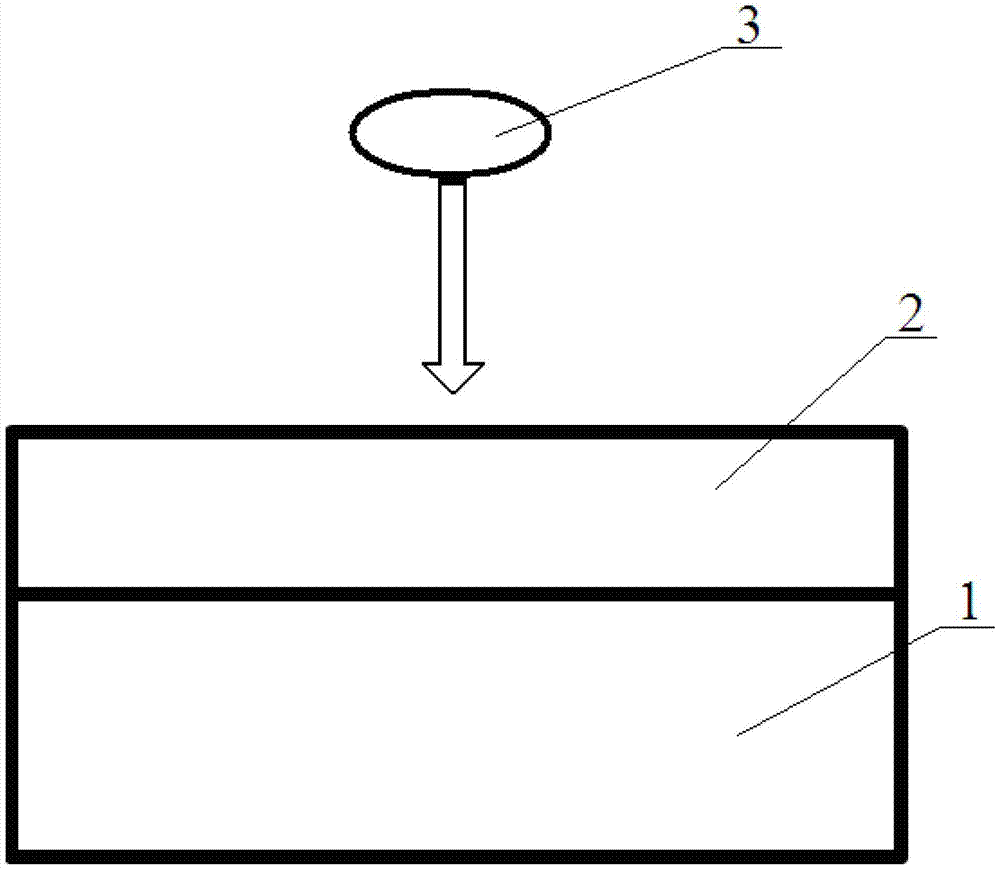

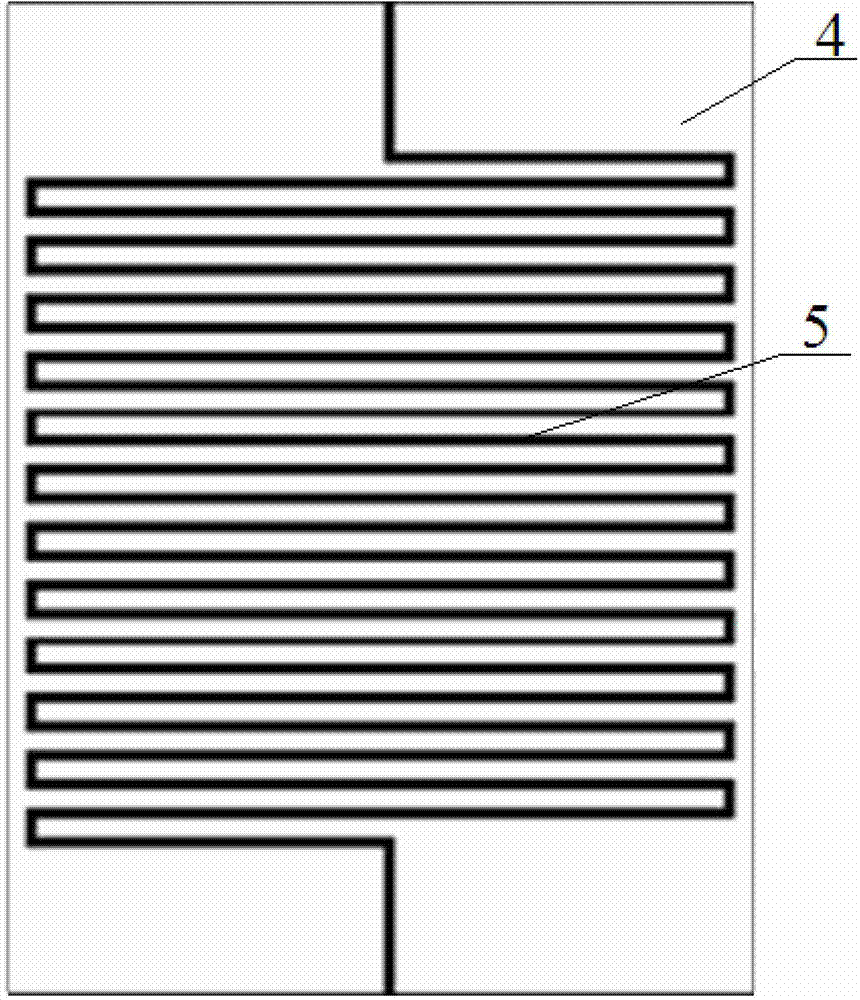

[0038] First, clean the base quartz glass, including the following steps: ultrasonic cleaning with organic cleaning solution for 8-12 minutes, ultrasonic cleaning with deionized water for 3-8 minutes, ultrasonic cleaning with MOS grade ethanol for 8-12 minutes, and ultrasonic cleaning with deionized water for 8-12 minutes. 12 minutes, blow dry with dry pure nitrogen. The organic cleaning solution is detergent, and the resistivity of deionized water is ≤18MΩ. The root mean square roughness of the substrate surface is greater than 0nm and less than 0.5nm.

[0039] Then nickel single-layer film is plated on the substrate quartz glass, adopting the DC magnetron sputtering method, comprising the following steps: before plating nickel single-layer film, the background vacuum degree of the sputtering chamber is lower than 2×10 -4 Pascal; the distance from the target to the substrate is 8 cm; the working mode of the sputtering target gun is constant power sputtering, and the sputteri...

Embodiment 2

[0045] First, the quartz glass of the substrate 1 is cleaned, including the following steps: ultrasonic cleaning with organic cleaning solution for 8-12 minutes, ultrasonic cleaning with deionized water for 3-8 minutes, ultrasonic cleaning with MOS grade ethanol for 8-12 minutes, and ultrasonic cleaning with deionized water for 8 minutes. -12 minutes, blow dry with dry pure nitrogen. The organic cleaning solution is detergent, and the resistivity of deionized water is ≤18MΩ. The root mean square roughness of the substrate surface is greater than 0nm and less than 0.5nm.

[0046] Then nickel single-layer film is plated on the substrate quartz glass, adopting the DC magnetron sputtering method, comprising the following steps: before plating nickel single-layer film, the background vacuum degree of the sputtering chamber is lower than 2×10 -4 Pascal; the distance from the target to the substrate is 8 cm; the working mode of the sputtering target gun is constant power sputtering,...

Embodiment 3

[0051] First, the quartz glass of the substrate 1 is cleaned, including the following steps: ultrasonic cleaning with organic cleaning solution for 8-12 minutes, ultrasonic cleaning with deionized water for 3-8 minutes, ultrasonic cleaning with MOS grade ethanol for 8-12 minutes, and ultrasonic cleaning with deionized water for 8 minutes. -12 minutes, blow dry with dry pure nitrogen. The organic cleaning solution is detergent, and the resistivity of deionized water is ≤18MΩ. The root mean square roughness of the substrate surface is greater than 0nm and less than 0.5nm.

[0052] Then nickel single-layer film is plated on the substrate quartz glass, adopting the DC magnetron sputtering method, comprising the following steps: before plating nickel single-layer film, the background vacuum degree of the sputtering chamber is lower than 2×10 -4 Pascal; the distance from the target to the substrate is 8 cm; the working mode of the sputtering target gun is constant power sputtering,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com