Preparation method of mesoporous-microporous composite molecular sieve

A composite molecular sieve and microporous molecular sieve technology, which is applied in the field of preparation of mesoporous-microporous composite molecular sieves, can solve the problems of inconspicuous mesoporous structure of composite molecular sieves, channel blockage, channel collapse, etc., so as to improve hydrothermal and thermal stability. , The effect of improving the ratio of silicon to aluminum and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

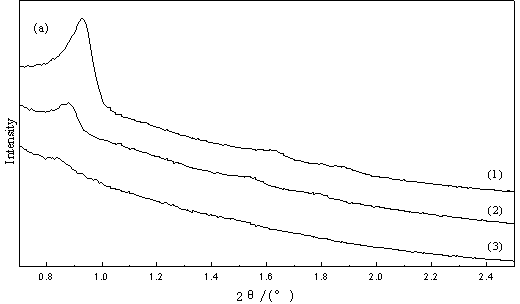

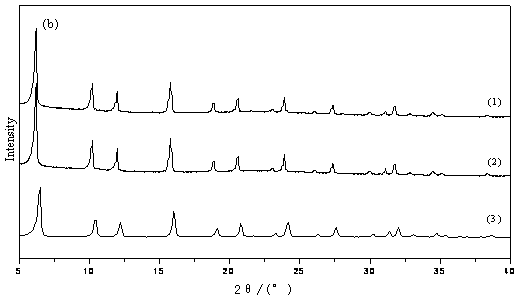

Image

Examples

Embodiment 1

[0027] Preparation of composite molecular sieve F-1:

[0028] (1) Add 200g tetraethyl orthosilicate to the HCl solution with a concentration of 0.28mol / L, and stir at 35°C for about 3 hours until it becomes a transparent solution;

[0029] (2) Dissolve 100g of diethanolamine in water, maintain the pH value at 3, and stir at 40°C for 2 hours to obtain a mixed solution containing cationic surfactant;

[0030] (3) Take 60g molecular sieve Y-1 (specific surface area 794 m 2 / g, pore volume 0.39 mL / g, average pore diameter 1.76nm, relative crystallinity 97%, acid content 0.632 mmol / g) was put into a hydrothermal furnace to react for 2 hours at 550°C and 2MPa pressure, and then taken out;

[0031] (4) Add the solution obtained in step (1) to the mixed solution obtained in step (2), stir at 40°C for 24 hours, then add 53g of molecular sieve Y-1 after hydrothermal treatment in step (3), and heat at 100°C Heat treatment in water for 48 hours, rinse the filter cake with a large amount...

Embodiment 2

[0033] Preparation of composite molecular sieve F-2:

[0034] (1) Add 200g tetraethyl orthosilicate to 0.28 mol / L HCl solution, stir at 35°C for about 3 hours until it becomes a transparent solution;

[0035] (2) Dissolve 50g of diethanolamine in water, maintain the pH value at 3, and stir at 40°C for 2 hours to obtain a mixed solution containing cationic surfactant;

[0036] (3) Take 150g molecular sieve Y-2 (specific surface area 759 m 2 / g, pore volume 0.37 mL / g, average pore diameter 1.85nm, relative crystallinity 96%, acid content 0.573 mmol / g) put into the hydrothermal furnace to react for 2 hours at 550℃ and 2MPa pressure, and then take it out;

[0037] (4) Add the solution obtained in step (1) to the mixed solution obtained in step (2), stir at 40°C for 24 hours, then add 107g of the molecular sieve Y-2 after hydrothermal treatment in step (3) and put it in water at 100°C Heat treatment for 48 hours, wash the filter cake with a large amount of deionized water until n...

Embodiment 3

[0039] Preparation of Composite Molecular Sieve F-3

[0040] (1) Add 200g tetraethyl orthosilicate to 0.30 mol / L nitric acid solution, stir at 35°C for about 3 hours until it becomes a transparent solution;

[0041] (2) Dissolve 50g of ethyleneimine in water, maintain the pH value at 3, and stir at 40°C for 2 hours to obtain a mixed solution containing cationic surfactant;

[0042] (3) Same as embodiment 1;

[0043] (4) Add the solution obtained in step (1) to the mixed solution obtained in step (2), stir at 40°C for 24 hours, then add 250g of the molecular sieve Y-1 after hydrothermal treatment in step (3) and put it in water at 100°C Heat treatment for 48 hours, wash the filter cake with a large amount of deionized water until neutral, dry at 120°C for 6 hours, and then bake at 550°C in an air atmosphere for 7 hours to remove surfactant molecules and obtain a microporous-mesoporous composite molecular sieve F-3, see Table 1 for the physical parameters of the composite mole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com