Silicon-containing organic luminescent material as well as preparation method and application of organic luminescent material

A luminescent material and organic technology, applied in luminescent materials, silicon organic compounds, organic chemistry, etc., can solve the problems that blue light materials cannot meet the needs of industrialization, and achieve the effects of improved luminous efficiency, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

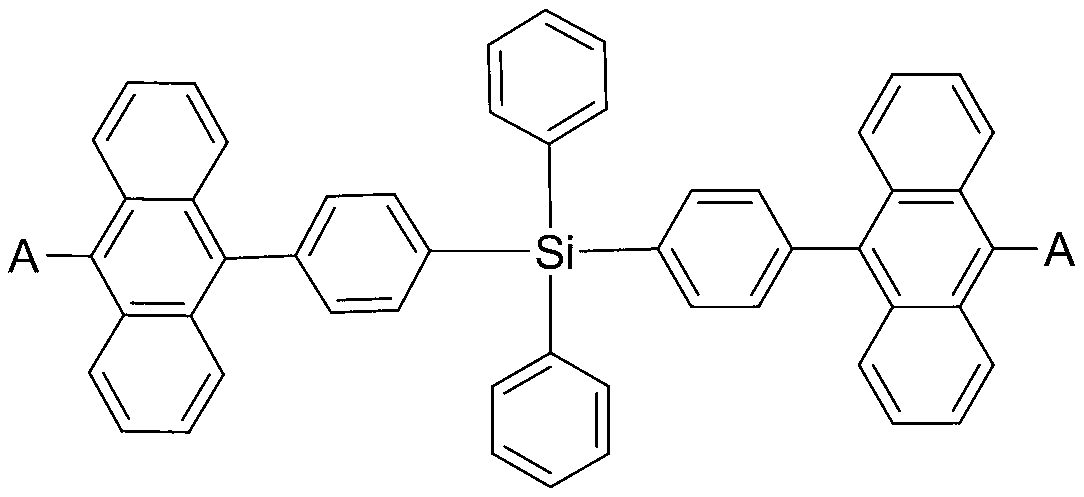

[0032] Add 34.49g of bis(4-bromophenyl)diphenylsilane, 15.67g of (10-(2-naphthyl)-9-anthracenyl)boronic acid, 20g of sodium carbonate, 250ml of tetrahydrofuran and 125ml of water into a three-necked flask, degas , add 0.9g of tetrakis(triphenylphosphine) palladium, raise the temperature to 70°C, reflux for 24 hours, cool to room temperature, after the solid precipitates, filter with suction, wash the filter cake with water, ethanol and ether, and dry to obtain bis( 38.89 g of 4-(10-(2-naphthyl)-9-anthracenyl)phenyl)diphenylsilane, the yield is over 90%, and the HPLC purity is over 98%. Mass spectrum: calculated value 941.24; found value 941.26. Elemental analysis: Calculated value for C: 91.88%; H: 5.14%; Si: 2.98%; Tested value for C: 91.86%; H: 5.12%; Si: 3.04%.

[0033] The specific synthetic route is shown in the following formula:

[0034]

Embodiment 2

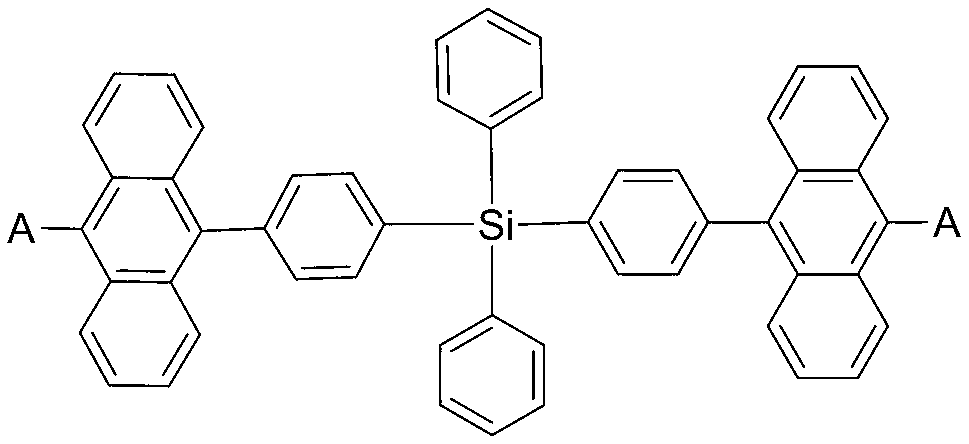

[0036] Mix 34.49g of bis(4-bromophenyl)diphenylsilane, 28.91g of (10-(9,9-dimethyl-2-fluorenyl)9-anthracenyl)boronic acid, 20g of sodium carbonate, 250ml of tetrahydrofuran and water Add 125ml into a three-neck flask, degas, add 0.9g of tetrakis(triphenylphosphine) palladium, heat up to 100°C, reflux for 30 hours, cool to room temperature, after the solid precipitates, filter with suction, and wash the filter cake with water, ethanol and ether After drying, 45.08 g of bis(4-(10-(2-fluorenyl)-9-anthracenyl)phenyl)diphenylsilane was obtained, with a yield of over 90% and an HPLC purity of over 98%. Mass Spectrum: Calculated 1073.44; Found 1073.42. Elemental analysis: calculated value C: 91.75%; H: 5.63%; Si: 2.62%; test value C: 91.76%; H: 5.62%; Si: 2.60%.

[0037] The specific synthetic route is shown in the following formula:

[0038]

Embodiment 3

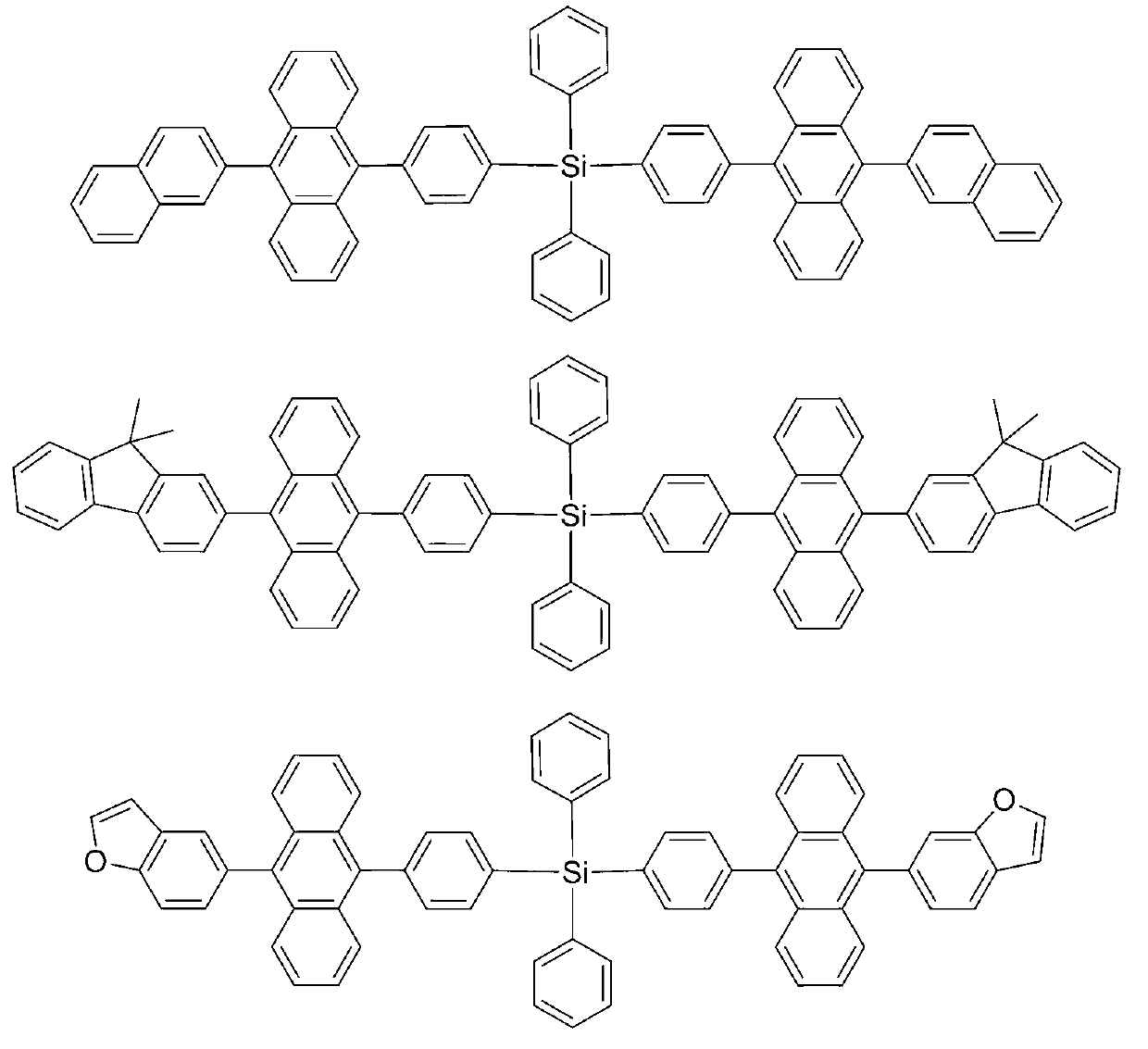

[0040] Add 34.49g of bis(4-bromophenyl)diphenylsilane, 23.59g of (10-(5-benzofuryl)9-anthracenyl)boronic acid, 20g of sodium carbonate, 250ml of tetrahydrofuran and 125ml of water into a three-necked flask, and remove gas, add tetrakis(triphenylphosphine) palladium 0.9g, heat up to 85°C, reflux for 27 hours, cool to room temperature, after the solid precipitates, filter with suction, wash the filter cake with water, ethanol and ether, and dry to obtain bis (4-(10-(2-Benzofuryl)-9-anthracenyl)phenyl)diphenylsilane 38.69g, yield over 90%, HPLC purity over 98%. Mass Spectrum: Calculated 921.16; Asserted 921.18. Elemental analysis: Calcd: C: 88.66%; H: 4.81%; O: 3.47%; Si: 3.05%; Tested: C: 88.64%; H: 4.82%; O: 3.48%;

[0041] The specific synthetic route is shown in the following formula:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com