Titanium alloy self-lubricating composite film and preparation method thereof

A titanium alloy and composite film technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of unsuitability for industrialized large-scale production, large friction coefficient, complex preparation process, etc., to reduce friction coefficient, Good lubrication and anti-friction performance, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

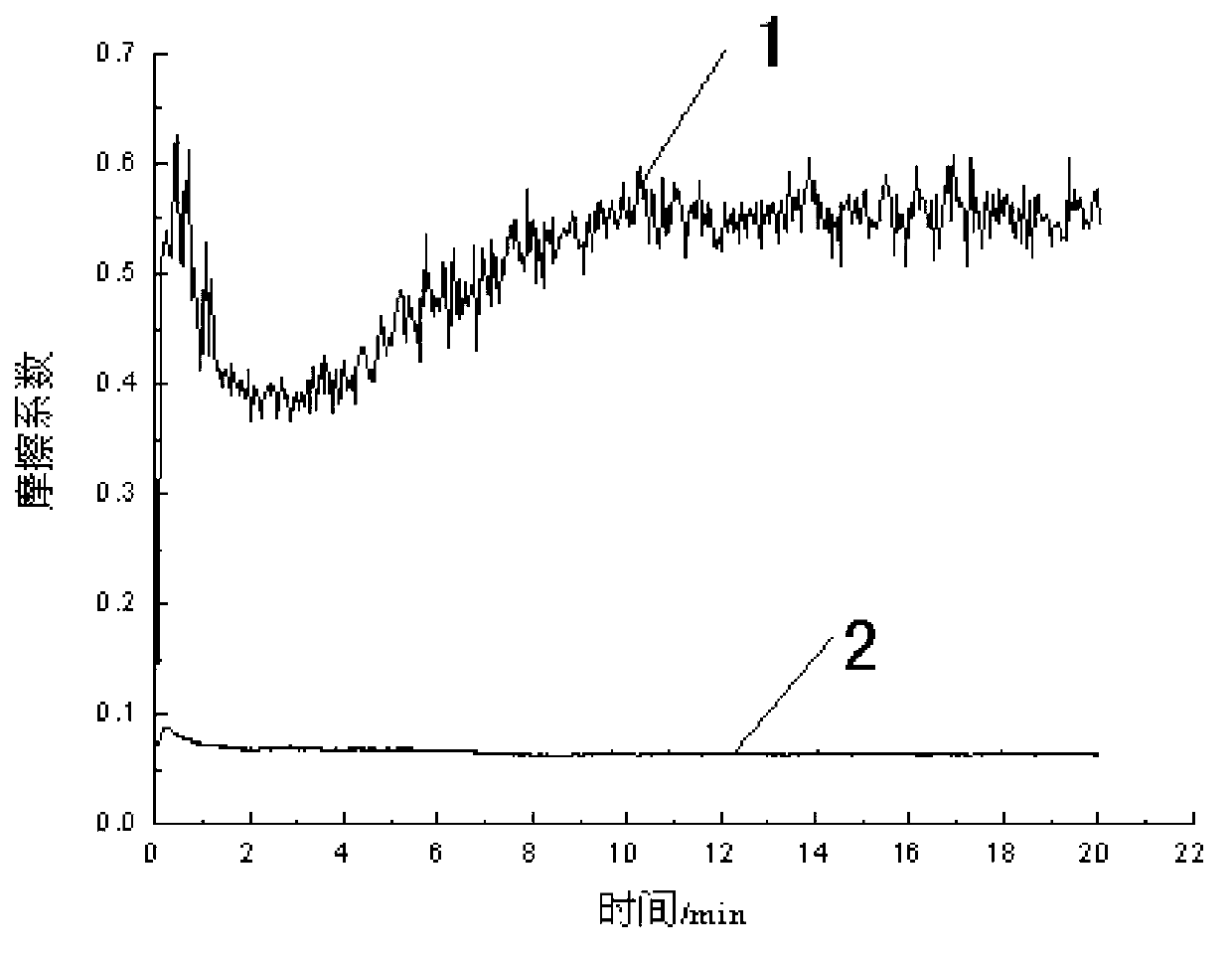

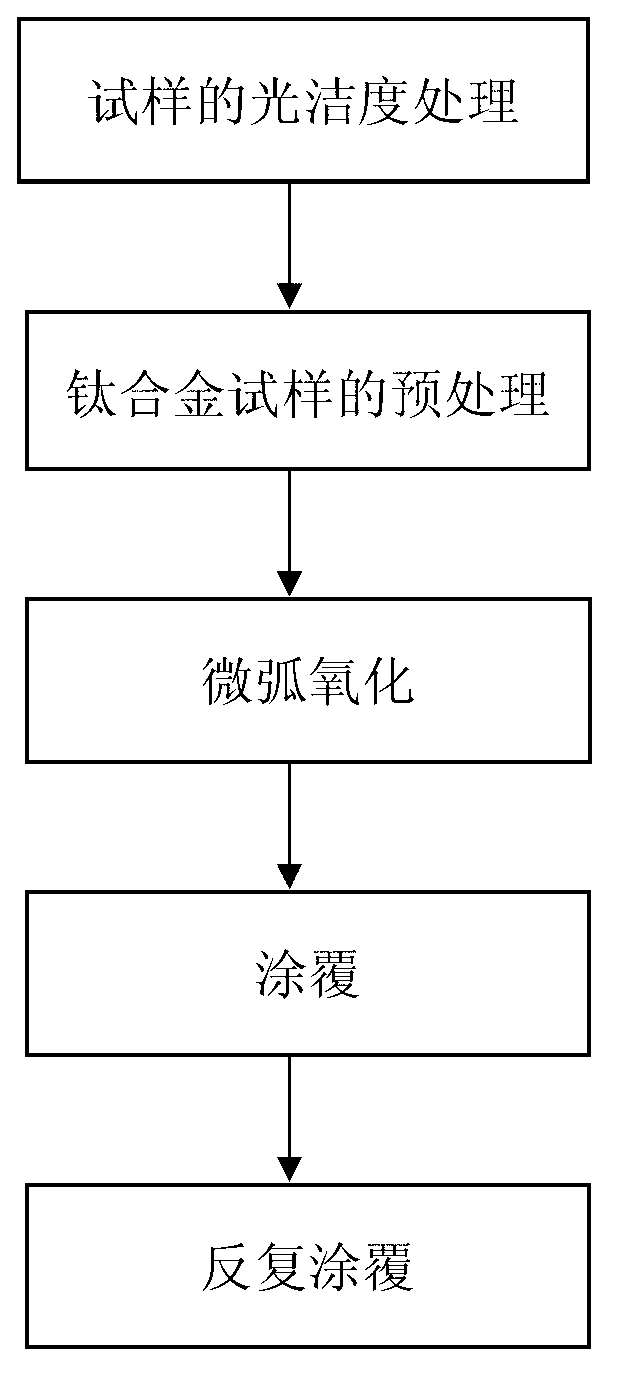

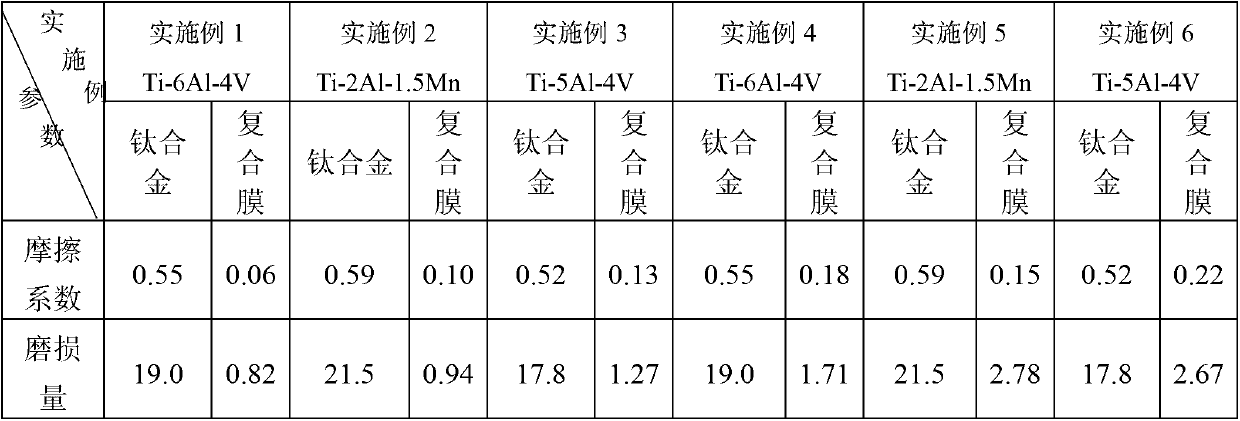

[0038] This embodiment is a Ti6Al4V titanium alloy self-lubricating composite film, and the external dimensions of the sample are 25mm×20mm×2.5mm.

[0039] The self-lubricating composite film is composed of a ceramic oxide film and an epoxy resin-based composite material coating, and the ceramic oxide film is prepared on the surface of the titanium alloy sample, and the epoxy resin-based composite material coating is prepared on the surface of the ceramic oxide film .

[0040] The ceramic oxide film contains 19.20-24.59% of Ti, 50.16-55.38% of O, 6.63-8.24% of P, 6.98-9.53% of Si and 7.74-9.46% of Al. In this embodiment, the ceramic oxide film contains 21.59% Ti, 53.38% O, 7.64% P, 7.53% Si, and 8.86% Al.

[0041] The Ti in the ceramic oxide film is mainly derived from the matrix, P and Si are respectively derived from sodium silicate and sodium hexametaphosphate in the electrolyte components, and the content of O in the film layer is relatively high, indicating that micro-ar...

Embodiment 2

[0058] This embodiment is a Ti-2Al-1.5Mn titanium alloy self-lubricating composite film, and the external dimensions of the sample are 25mm×20mm×2.5mm.

[0059] The self-lubricating composite film is composed of a ceramic oxide film and an epoxy resin-based composite material coating, and the ceramic oxide film is prepared on the surface of the titanium alloy sample, and the epoxy resin-based composite material coating is prepared on the surface of the ceramic oxide film .

[0060] The ceramic oxide film contains 19.0-24.59% of Ti, 50.16-55.38% of O, 6.6-8.24% of P, 6.98-9.53% of Si and 7.74-9.46% of Al. In this embodiment, the ceramic oxide film contains 24.12% Ti, 50.16% O, 6.98% P, 9.53% Si, and 8.21% Al.

[0061] The Ti in the ceramic oxide film is mainly derived from the matrix, P and Si are respectively derived from sodium silicate and sodium hexametaphosphate in the electrolyte components, and the content of O in the film layer is relatively high, indicating that micro-a...

Embodiment 3

[0077] This embodiment is a Ti-5Al-4V titanium alloy self-lubricating composite film, and the external dimensions of the sample are 25mm×20mm×2.5mm.

[0078] The self-lubricating composite film is composed of a ceramic oxide film and an epoxy resin-based composite material coating, and the ceramic oxide film is prepared on the surface of the titanium alloy sample, and the epoxy resin-based composite material coating is prepared on the surface of the ceramic oxide film .

[0079] The ceramic oxide film contains 19.0-24.59% of Ti, 50.16-55.38% of O, 6.6-8.24% of P, 6.98-9.53% of Si and 7.74-9.46% of Al. In this embodiment, the ceramic oxide film contains 19.20% Ti, 53.43% O, 8.24% P, 9.18% Si, and 8.95% Al.

[0080] The Ti in the ceramic oxide film is mainly derived from the matrix, P and Si are respectively derived from sodium silicate and sodium hexametaphosphate in the electrolyte components, and the content of O in the film layer is relatively high, indicating that micro-ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com