Yb<3+> activated boron tungstate up-conversion luminescent material and preparation method thereof

A technology of luminescent materials and borotungstate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems such as the preparation method and application of borotungstate that have not been reported in the literature, and achieve low equipment requirements, convenient synthesis, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the chemical formula La 0.95 Yb 0.05 BWO 6 The stoichiometric ratio of each element in , respectively weigh lanthanum oxide La 2 o 3 : 0.5159 g, ytterbium oxide Yb 2 o 3 : 0.0328 g, boric acid H 3 BO 3 : 0.31 g, tungsten oxide WO 3 : 0.7883 g, after grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first calcination, the temperature is 300 ℃, the calcination time is 4 hours, then cool to room temperature, and take out the sample. After the first calcination of the raw materials, the mixture is fully mixed and ground again, and then sintered for the second time at 1000°C in an air atmosphere for 8 hours, and then cooled to room temperature to obtain a powdery phosphor.

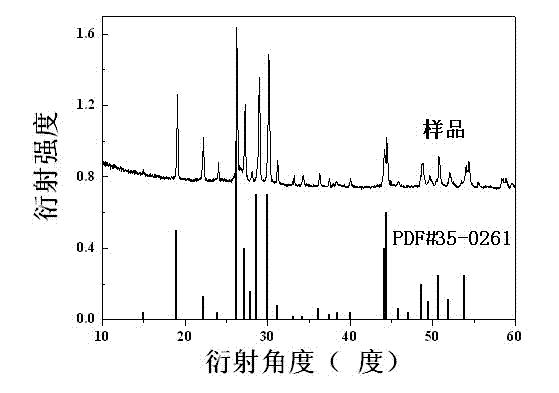

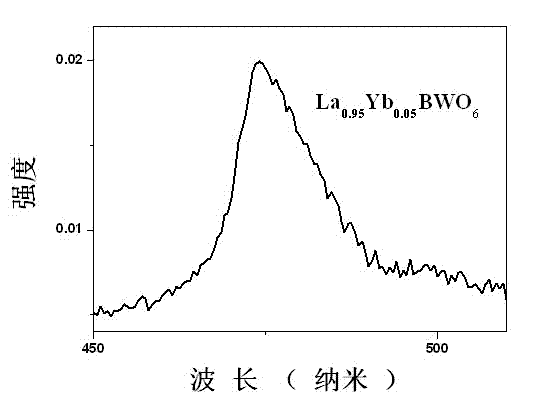

[0040] See attached figure 1 According to the comparison of the X-ray powder diffraction pattern of the sample prepared according to the technical scheme of this embodiment and the standard card PDF#35-0261, the prepared material is a single-phase m...

Embodiment 2

[0044] According to the chemical formula La 0.9 Yb 0.1 BWO 6 The stoichiometric ratio of each element in , weigh lanthanum nitrate La(NO 3 ) 3 ?6H 2 O: 1.299 g, ytterbium oxide Yb 2 o 3 : 0.0657 g, boric acid H 3 BO 3 : 0.31 g, tungsten oxide WO 3 : 0.7883 g, after grinding and mixing uniformly in an agate mortar, choose the air atmosphere for the first calcining, the temperature is 350 ° C, the calcining time is 2 hours, then cool to room temperature, and take out the sample. After the first calcination of the raw materials, the mixture is thoroughly mixed and ground evenly, and the second sintering is carried out at 800°C in an air atmosphere. The sintering time is 7 hours, and cooled to room temperature to obtain a powdery phosphor.

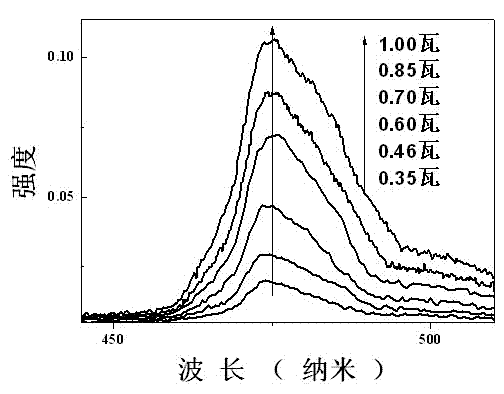

[0045] See attached Figure 4 , is the up-conversion luminescence spectrum obtained under the excitation of infrared light at 975 nm and excitation energy intensity of 0.46 watts by the sample prepared according to the technical sche...

Embodiment 3

[0047] According to the chemical formula Pr 0.8 Yb 0.2 BWO 6 The stoichiometric ratio of each element in , respectively weighed praseodymium oxide Pr 6 o 11 : 0.4540 g, ytterbium oxide Yb 2 o 3 : 0.1314 g, boron oxide B 2 o 3 : 0.1184 g, tungsten oxide WO 3 : 0.7883 g, after grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first calcination, the temperature is 650 ° C, the calcination time is 6 hours, then cool to room temperature, and take out the sample. After the first calcination of the raw materials, the mixture is thoroughly mixed and ground evenly, and the second sintering is carried out at 900°C in an air atmosphere. The sintering time is 6 hours, and cooled to room temperature to obtain powdery phosphor.

[0048] See attached Figure 5 , is the up-conversion luminescence spectrum obtained under the excitation of infrared light at 975 nm and excitation energy intensity of 0.60 watts by the sample prepared according to the tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com