Method for locally producing in-situ organic fertilizer in crop straw field and application

A technology of crop straw and organic fertilizer, applied in the field of agricultural technology and environmental protection, to achieve the effect of improving soil organic matter and fertility, improving soil fertility and productivity, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

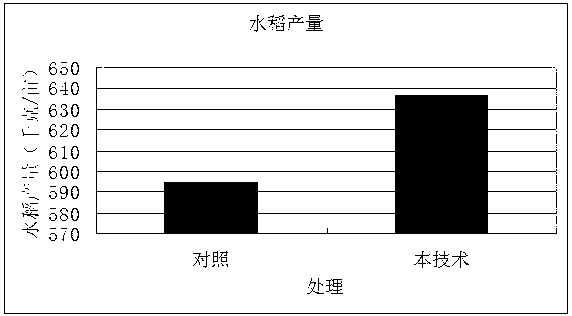

Image

Examples

Embodiment 1

[0021] 1.在小麦秸秆收获后,将秸秆粉碎成大约1cm长的秆段;

[0022] 2.按小麦秸秆质量15%的量在田间撒施畜禽粪便和0.01%的生石灰;

[0023] 3.每1000千克小麦秸秆加入1千克尿素、商品微生物制剂木霉100亿个活菌体(或孢子)、青霉100亿个活菌体(或孢子)、曲霉100亿个活菌体(或孢子)、放线菌10亿个活菌体(或孢子)、毛格盖菌100亿活菌体(或孢子)、链霉菌100亿个活菌体(或孢子)、节杆菌100亿个活菌体(或孢子)、假单胞菌100亿个活菌体(或孢子)和黄单胞菌100亿个活菌体(或孢子),拌匀,灌水,保持田间土壤含水量在40%wt;

[0024] 4.夏季14天后,小麦秸秆经过生物催化转化变成有机肥;

[0025] 5.耕翻土壤,再补施复合肥、氮肥或磷肥做基肥,种植水稻。

[0026]

Embodiment 2

[0028] 1.在水稻秸秆收获后,将秸秆粉碎成大约1cm长的秆段;

[0029] 2.按水稻秸秆质量35%的量在田间撒施畜禽粪便和0.02%的生石灰;

[0030] 3.每1000千克水稻秸秆加入5千克尿素、商品微生物制剂木霉300亿个活菌体(或孢子)、青霉300亿个活菌体(或孢子)、曲霉300亿个活菌体(或孢子)、放线菌30亿个活菌体(或孢子)、毛格盖菌300亿活菌体(或孢子)、链霉菌300亿个活菌体(或孢子)、节杆菌300亿个活菌体(或孢子)、假单胞菌300亿个活菌体(或孢子)和黄单胞菌300亿个活菌体(或孢子),拌匀,灌水,保持田间土壤含水量在50%;

[0031] 4.秋季 21天后,水稻秸秆经过生物催化转化变成有机肥;

[0032] 5.耕翻土壤,再补施复合肥、氮肥或磷肥做基肥,种植小麦。

[0033]

Embodiment 3

[0035] 1.在小麦秸秆收获后,将秸秆粉碎成大约1cm长的秆段;

[0036] 2.按小麦秸秆质量50%的量在田间撒施畜禽粪便和0.05%的生石灰;

[0037] 3.每1000千克小麦秸秆加入10千克硫酸铵、商品微生物制剂木霉600亿个活菌体(或孢子)、青霉600亿个活菌体(或孢子)、曲霉600亿个活菌体(或孢子)、放线菌60亿个活菌体(或孢子)、毛格盖菌600亿活菌体(或孢子)、链霉菌600亿个活菌体(或孢子)、节杆菌600亿个活菌体(或孢子)、假单胞菌600亿个活菌体(或孢子)和黄单胞菌600亿个活菌体(或孢子),拌匀,灌水,保持田间土壤含水量在60%;

[0038] 4.夏季14天后,小麦秸秆经过生物催化转化变成有机肥;

[0039] 5. Plow the soil, then apply compound fertilizer, nitrogen fertilizer or phosphorus fertilizer as base fertilizer, and plant corn.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com