Method for preparing propylene and ethylene from alcohol

A technology for propylene and ethylene, applied in the field of preparing propylene and ethylene, can solve the problems of poor thermal stability of catalyst, low propylene/ethylene ratio, and rapid deactivation, so as to improve hydrothermal stability, improve propylene selectivity, and improve shape selection. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 70% NaZSM-5 molecular sieve (SiO 2 / Al 2 o 3 molar silicon-aluminum ratio 200) catalyst precursor, first roasted under nitrogen flow at 600°C for 4 hours to release templates and other volatiles, then exchanged with 0.1M hydrochloric acid 1000 ml at 80°C, repeated four times, and then washed with deionized water until no Chloride, dried at 120°C for later use.

[0041] Add 20 grams of the above-mentioned catalyst to 100 milliliters of 5% silver nitrate solution, exchange at room temperature for 3 hours, then filter the solution, dry at 120° C. for 10 hours, and then roast at 550° C. for 2 hours to obtain catalyst A, containing Ag2. 0%.

[0042] Install 3 grams of catalyst A in a fixed-bed reactor of Φ15 mm, add an equal amount of industrial methanol to deionized water to prepare a 50% methanol solution, and prepare the solution at a methanol weight space velocity of 3 hours -1 , The reaction temperature is 500°C, and the catalyst performance is evaluated under norma...

Embodiment 2~11

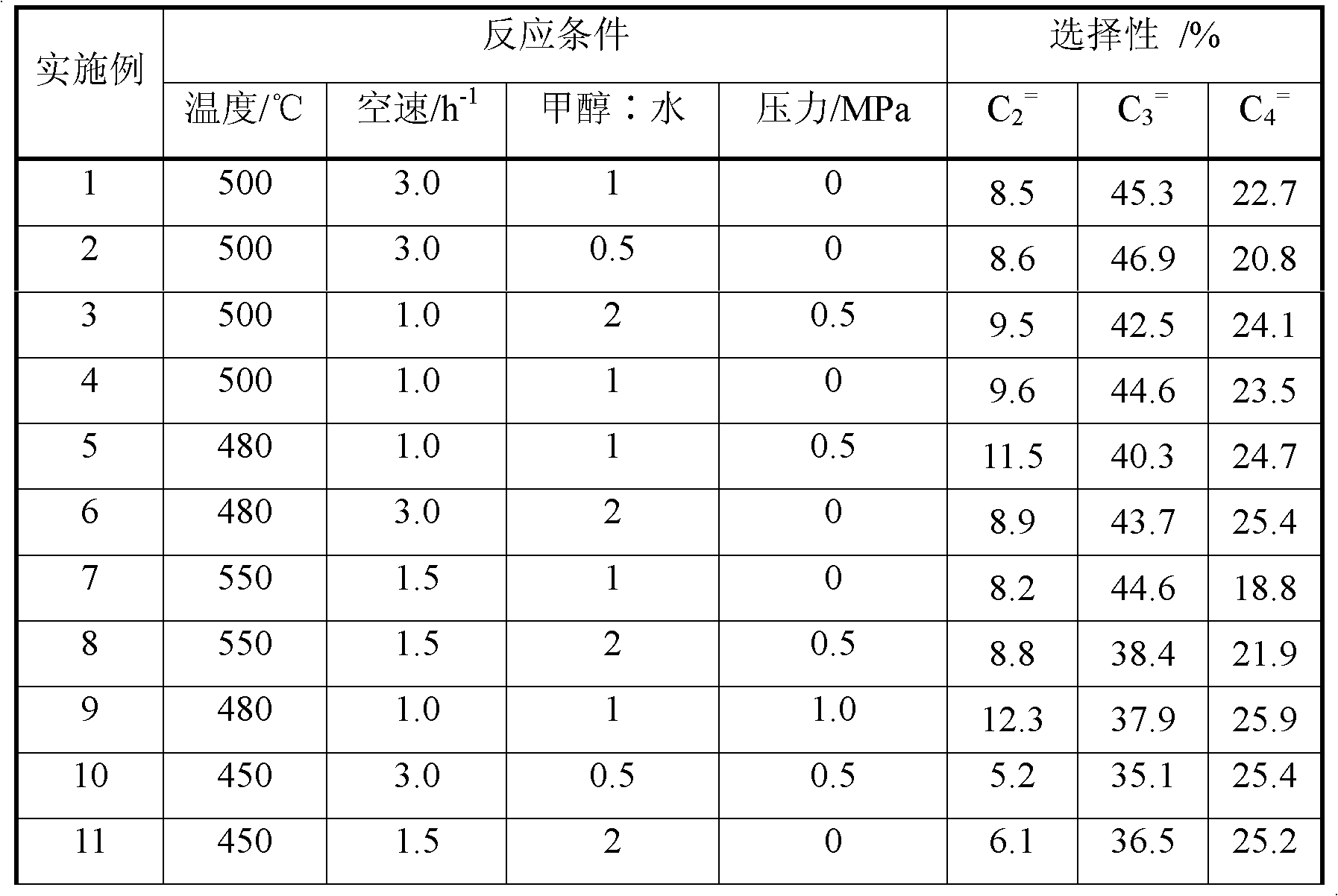

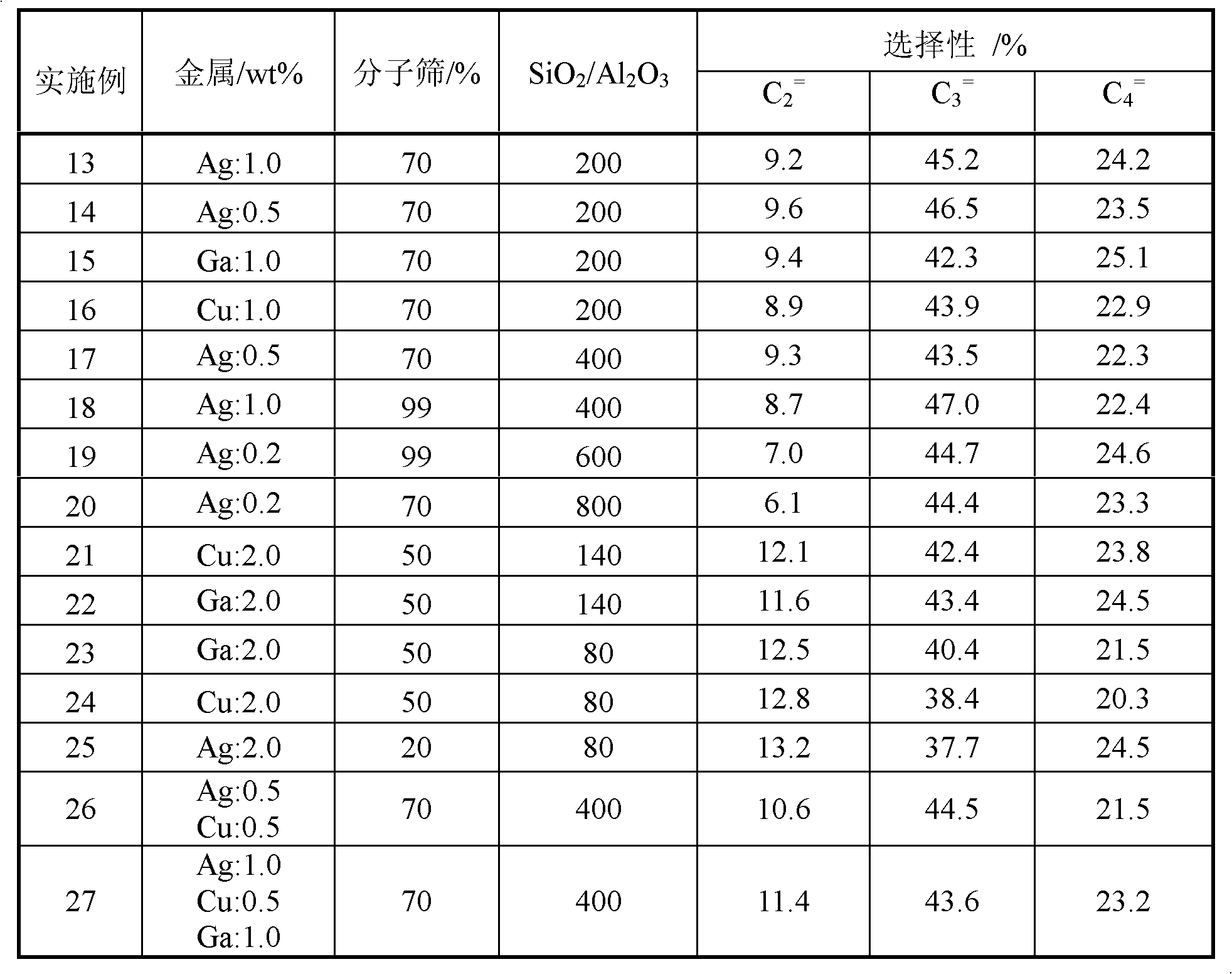

[0044] With the catalyst of Example 1, the reaction conditions were changed to obtain the evaluation result list 1.

[0045] Reaction performance of catalyst under different reaction conditions in table 1

[0046]

Embodiment 12

[0048] Carry out catalyst lifetime test under embodiment 4 catalyst and reaction condition, its result is as table 2:

[0049] Table 2 Catalyst Lifetime Evaluation

[0050] Response time (hours)

[0051] Catalyst deactivation is mainly caused by carbon deposition, and the catalyst can be regenerated by simply burning the catalyst with air, and its reactivity can be basically restored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com