Thymalfasin chitosan / beta-cyclodextrin composite microsphere drug delivery system and preparation method

A new technology of composite microspheres and thymus method, which is applied in the field of medicine, can solve the problems of poor stability of preparations and require refrigerated storage, and achieve the effect of simple and feasible preparation process, good reproducibility, and avoiding degradation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

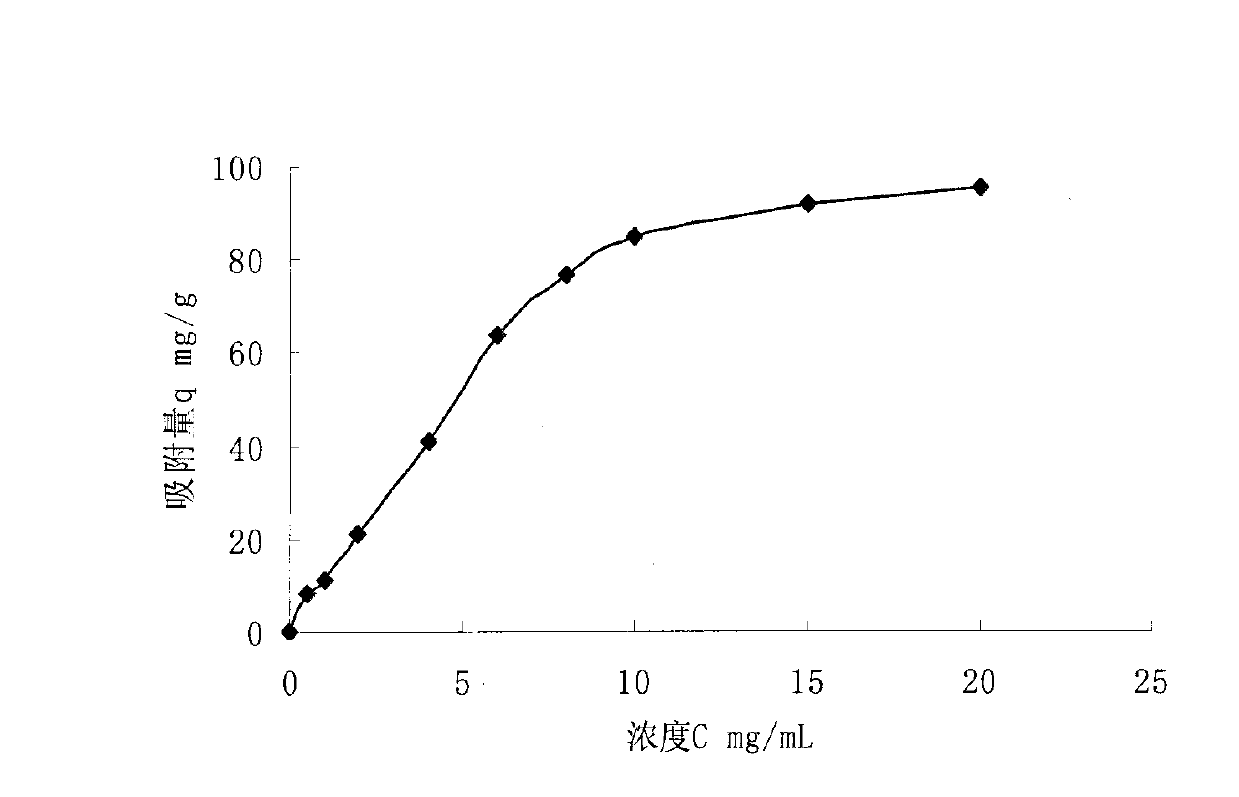

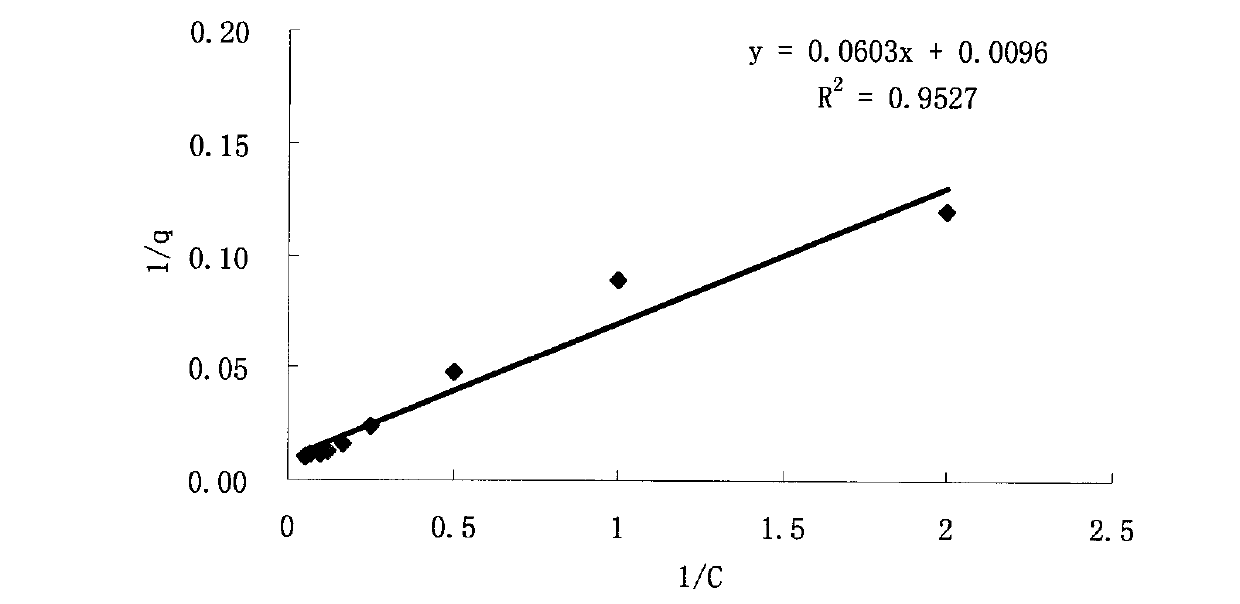

Image

Examples

Embodiment 1

[0045] Weigh 0.2g of chitosan powder and disperse it in 10mL, 2% acetic acid aqueous solution, fully dissolve, let stand to drain the air bubbles to obtain chitosan acetic acid aqueous solution; weigh 1g of β-cyclodextrin into the reaction bottle, add 20mL to Ionized water, mechanically stirred (can be properly heated) to dissolve completely, to obtain an aqueous solution containing β-cyclodextrin; slowly add chitosan acetic acid aqueous solution to the aqueous solution containing β-cyclodextrin, stir evenly, as the water phase; Add 60 mL of liquid paraffin, 1.8 mL of span-80 and 0.3 g of dispersant magnesium stearate to another reaction bottle to form an oil phase; slowly add the water phase into the oil phase, stir until the solution is emulsified and dispersed into beads of appropriate size, Slowly add 0.5mL of 25% glutaraldehyde (crosslinking agent) solution to crosslink and solidify, stir rapidly, collect the precipitate after 2h, filter with suction, wash repeatedly with ...

Embodiment 2

[0049] Weigh 0.6g of chitosan powder and disperse it in 10mL, 2% acetic acid aqueous solution, fully dissolve, let stand to drain out the air bubbles, and obtain chitosan acetic acid aqueous solution; weigh 0.6g of β-cyclodextrin into the reaction bottle, add 20mL Deionized water, mechanical stirring (can be properly heated) to dissolve completely, to obtain an aqueous solution containing β-cyclodextrin; slowly add chitosan acetic acid aqueous solution to the aqueous solution containing β-cyclodextrin, stir evenly, as the water phase; In another reaction bottle, add 120mL of a mixture of liquid paraffin and petroleum ether, 6mL of span-80 and 1g of dispersant magnesium stearate to form the oil phase; slowly add the water phase into the oil phase, stir until the solution is emulsified and dispersed to a suitable size Add 2.5mL of 25% glutaraldehyde (cross-linking agent) solution to cross-link and solidify, collect the precipitate after 2h, wash repeatedly with isopropanol three ...

Embodiment 3

[0053] Weigh 0.15g of chitosan powder and disperse it in 10mL, 2% acetic acid aqueous solution, fully dissolve, let stand to drain out the air bubbles, and obtain chitosan acetic acid aqueous solution; weigh 1.5g of β-cyclodextrin into the reaction bottle, add 20mL of deionized water, mechanically stirred (can be properly heated) to dissolve completely, to obtain an aqueous solution containing β-cyclodextrin; slowly add chitosan acetic acid aqueous solution to the aqueous solution containing β-cyclodextrin, stir evenly, as the water phase ;Add 30mL liquid paraffin, 15mL span-80 and 1.5g dispersant magnesium stearate to another reaction bottle to form the oil phase; slowly add the water phase to the oil phase, stir until the solution is emulsified and dispersed into beads of appropriate size , adding 0.6 mL of 25% glutaraldehyde (cross-linking agent) solution to cross-link and solidify, collect the precipitate after 2 hours, wash repeatedly with ethanol three times, and dry to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com