Wolfram-copper composite powder preparation method

A technology of composite powder and mixed liquid, which is applied in the field of powder preparation, can solve problems such as poor sintering performance and difficulty in reducing preparation costs, and achieve good sintering stability, low degree of agglomeration, and scientific preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] Step 1, first mix water, copper nitrate, tartaric acid, ammonium paratungstate and citric acid according to the molar ratio of 440:0.9:2:0.067:1.620, and stir at 50°C for 7h; wherein, the water is deionized water, and Mixture. Then add polyethylene glycol to the mixture, and stir at 60°C until it forms a gel; wherein, the molar ratio of polyethylene glycol to copper nitrate in the mixture is 0.0022:0.9, and polyethylene glycol is polyethylene glycol. Ethylene glycol 20000.

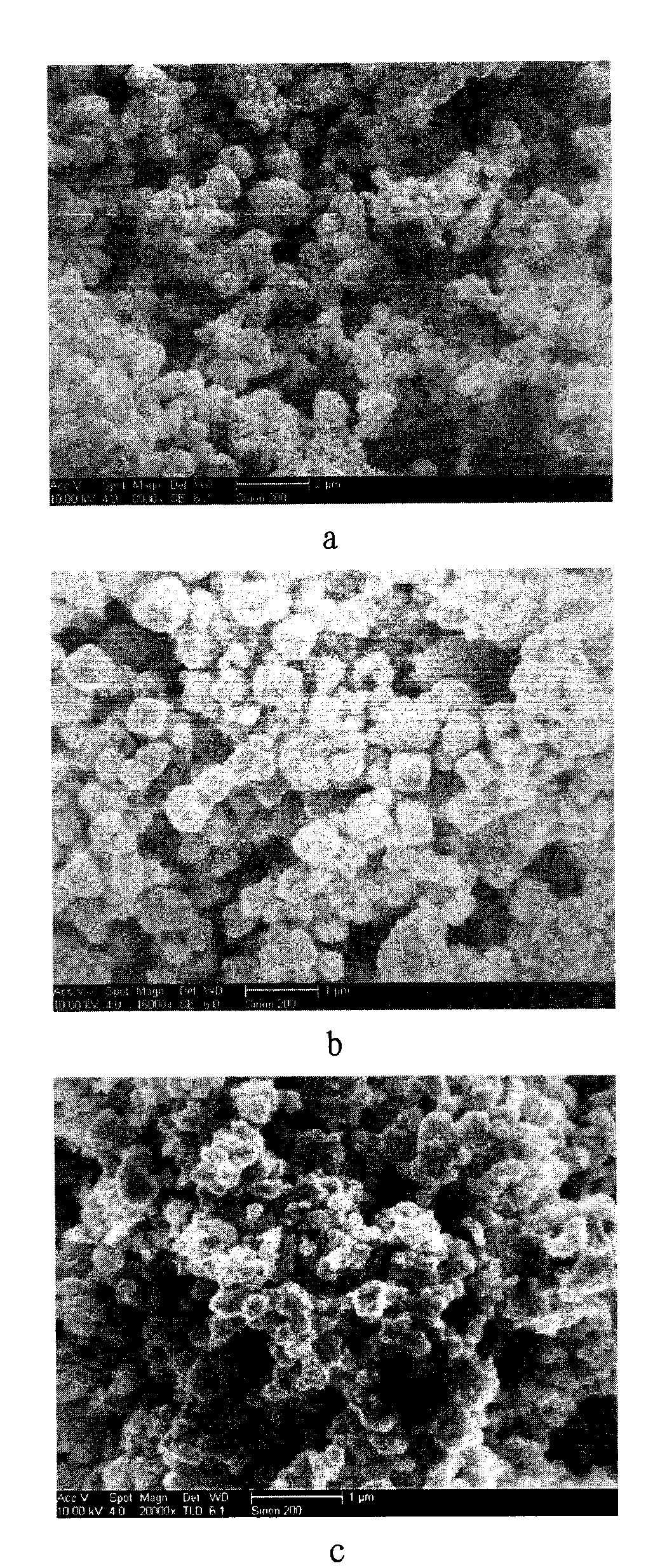

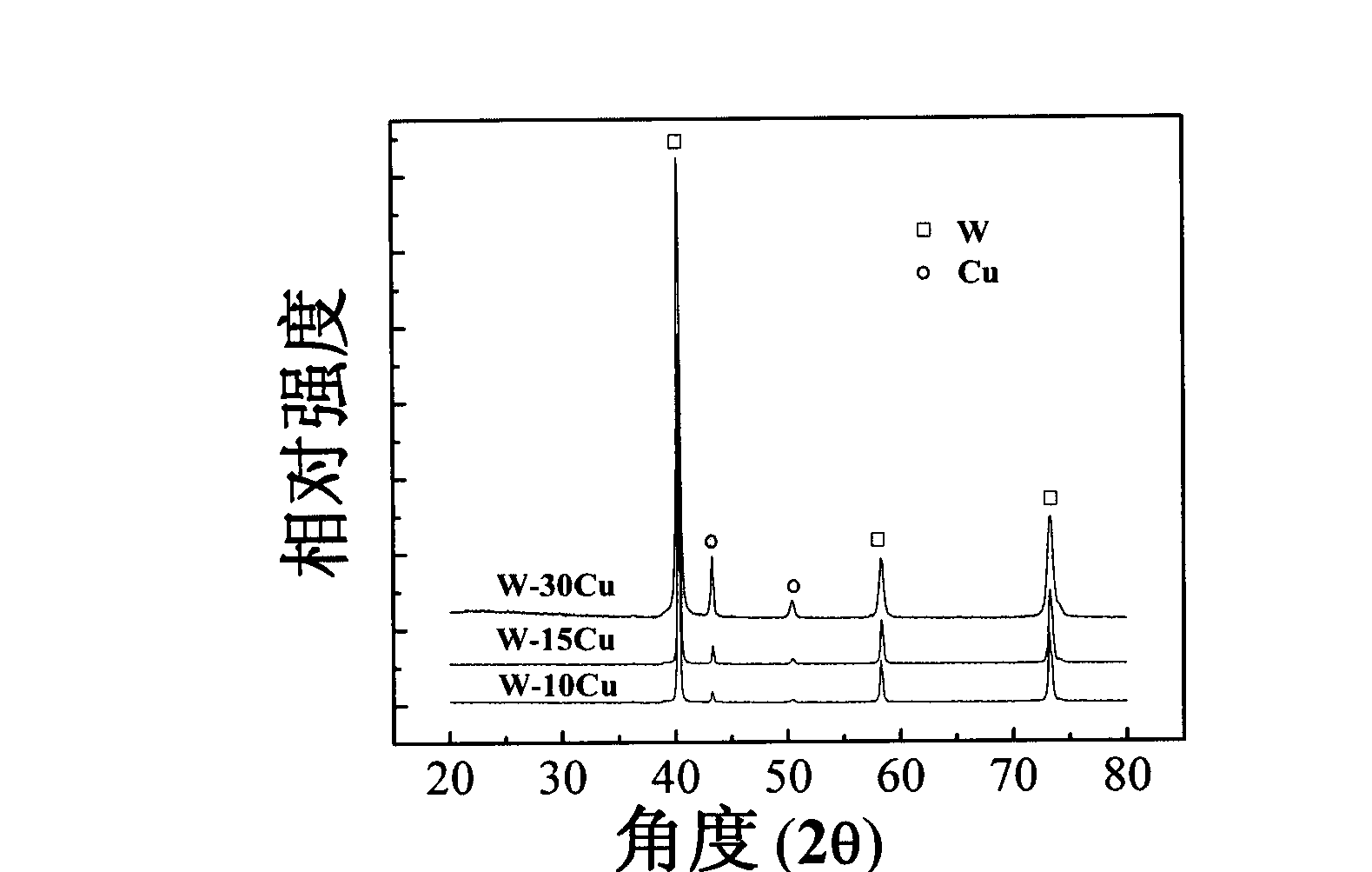

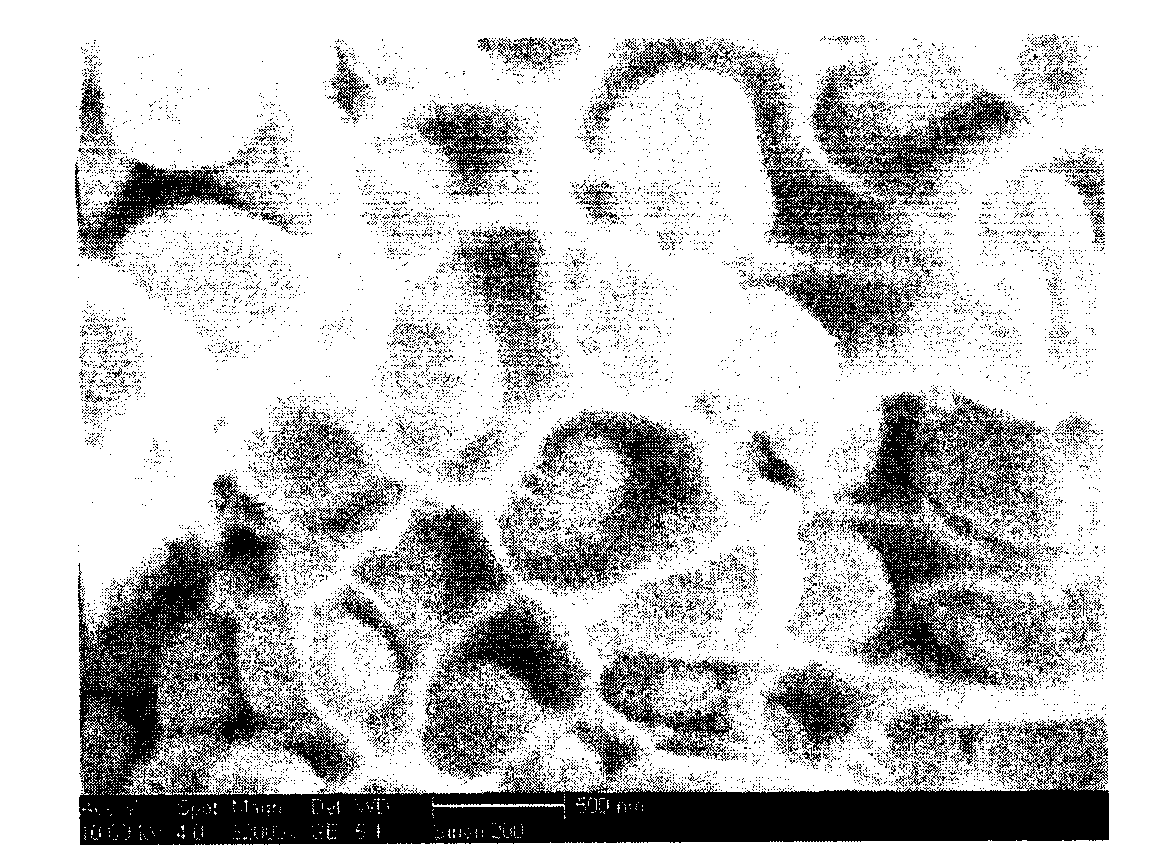

[0022] In step 2, the gel was first dried at 100°C for 16 hours to obtain a dry gel, and then the dry gel was placed at 290°C for 4.5 hours and 540°C for 5.5 hours to obtain an intermediate product. Next, the intermediate product was placed in a reducing gas atmosphere, and reduced at 760 ° C for 5 h; wherein, the reducing gas was hydrogen, and the following figure 1 c. Approximate to image 3 and Figure 4 shown, and as figure 2 The tungsten-co...

Embodiment 2

[0024] The concrete steps of preparation are:

[0025] Step 1, first mix water, copper nitrate, tartaric acid, ammonium paratungstate and citric acid according to the molar ratio of 445:0.95:2:0.115:2.781, and then stir at 53°C for 6.5h; wherein, the water is deionized water, to obtain a mixture. Add polyethylene glycol to the mixture, and stir at 63°C until it forms a gel; wherein, the molar ratio of polyethylene glycol to copper nitrate in the mixture is 0.0023:0.95, and polyethylene glycol is polyethylene glycol. Ethylene glycol 20000.

[0026] In step 2, the gel was dried at 105°C for 15 hours to obtain a dry gel, and then the dry gel was placed at 295°C for 4.3 hours and 545°C for 5.3 hours to obtain an intermediate product. Next, put the intermediate product in a reducing gas atmosphere, and reduce it at 770°C for 4.5 hours; wherein, the reducing gas is hydrogen, and the obtained product is approximately figure 1 b. image 3 and Figure 4 shown, and as figure 2 Th...

Embodiment 3

[0028] The concrete steps of preparation are:

[0029] Step 1, first mix water, copper nitrate, tartaric acid, ammonium paratungstate and citric acid according to the molar ratio of 450:1:2:0.164:3.942, and then stir at 55°C for 6h; wherein, the water is deionized water to obtain Mixture. Then add polyethylene glycol to the mixed solution, and stir it at 65°C until it forms a gel; wherein, the molar ratio of polyethylene glycol to copper nitrate in the mixed solution is 0.0024:1, and polyethylene glycol is polyethylene glycol. Ethylene glycol 20000.

[0030] In step 2, the gel was first dried at 110° C. for 14 hours to obtain a dry gel, and then the dry gel was placed at 300° C. for 4 hours and 550° C. for 5 hours to obtain an intermediate product. Next, the intermediate product is placed in a reducing gas atmosphere, and reduced at 780 ° C for 4 h; wherein, the reducing gas is hydrogen, and the following figure 1 b. image 3 and Figure 4 shown, and as figure 2 The tun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com