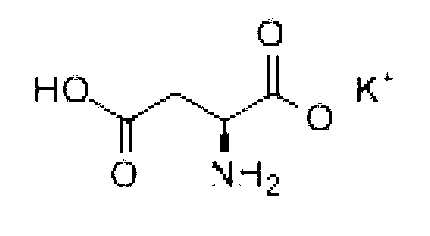

Potassium aspartate preparation method

A technology of potassium aspartate and aspartic acid is applied in the preparation of organic compounds, preparation of cyanide reaction, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

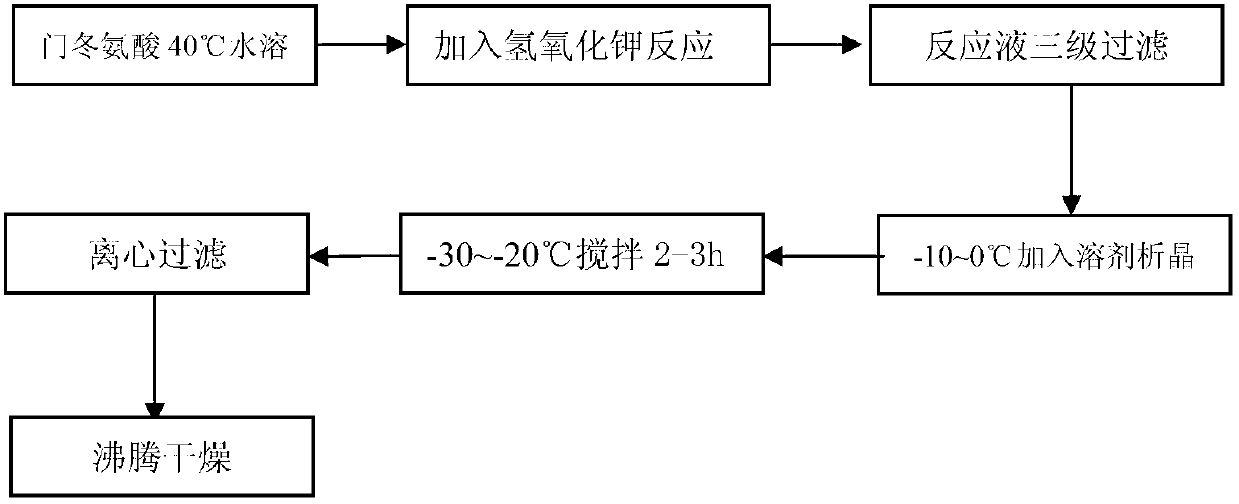

Method used

Image

Examples

Embodiment 1

[0035] Dissolve 133.1g of aspartic acid in 80g of purified water and stir at 30°C until completely dissolved. Add 80g of potassium hydroxide to react. At this time, the pH of the system is 8.0. Add 8.55g of activated carbon to the reaction solution at a temperature of 40°C to decolorize for 30 minutes at 30°C. Filter while it is hot, and filter through a carbon filter, a 1μm filter membrane (the material is PTFE), 0.45μm filter membrane (material is PTFE) three-stage filtration to obtain filtrate.

[0036] The filtrate was transferred to a crystallization tank (triangular flask, 1000ml in size), and an aqueous solution of 95% ethanol as an organic solvent three times the amount of water was slowly added, the solution gradually became cloudy, and the temperature was controlled at -10 to -8°C until the addition was complete. Keep the temperature at -25°C for 2 hours, then filter. The white product was obtained by filtration, washed with a small amount of ethanol solution (30ml)...

Embodiment 2

[0037] Dissolve 133.1g of aspartic acid in 93g of purified water and stir at 30°C until completely dissolved. Add 100g of potassium hydroxide to react, the pH of the system is 7.5, add 8.55g of activated carbon to the reaction solution at 40°C for decolorization at 30°C for 30 minutes, filter while hot, and pass through three stages of filtration of activated carbon, 1μm filter membrane, and 0.45μm filter membrane respectively. A filtrate was obtained.

[0038] Slowly add an aqueous solution of organic solvent 95% ethanol three times the amount of water to the filtrate, the solution becomes cloudy gradually, and the temperature is controlled at -9°C until the addition is complete. Keep the temperature at -20°C for 2.5 hours, then filter. The white product was obtained by filtration, washed with 30 ml of ethanol as a solvent, and then dried under reduced pressure at 30° C. for 8.5 hours. The weight loss on drying was 6.8%, and the finished product yield of potassium aspartate...

Embodiment 3

[0040] Dissolve 133.1 g of aspartic acid in 106 g of purified water and stir at 30°C until completely dissolved. Add 93g of potassium hydroxide to react, the pH of the system is 7.0, and the reaction solution is filtered while hot at a temperature of 40°C, and is filtered through three stages of activated carbon, 1 μm filter membrane and 0.45 μm filter membrane respectively to obtain the filtrate.

[0041] Slowly add an aqueous solution of organic solvent 95% ethanol three times the amount of water to the filtrate, the solution becomes cloudy gradually, and the temperature is controlled at -9°C until the addition is complete. Keep the temperature at -20°C for 2.5 hours, then centrifuge and filter. The white product was obtained by filtration, and the filter cake was washed with 30 ml of ethanol, and then dried under reduced pressure at 30° C. for 9 hours. The weight loss on drying was 7.0%, and the finished product yield of potassium aspartate was 96.1%, and the content was 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com