Zinc oxide composite material modified by phthalocyanines copper and producing method and function thereof

A composite material, copper phthalocyanine technology, applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of difficult zinc oxide, reduced specific surface area of zinc oxide, difficult gas-sensing properties, etc., to achieve easy industrialization Production and preparation methods are scientific, and the effect of simple preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The concrete steps of preparation are:

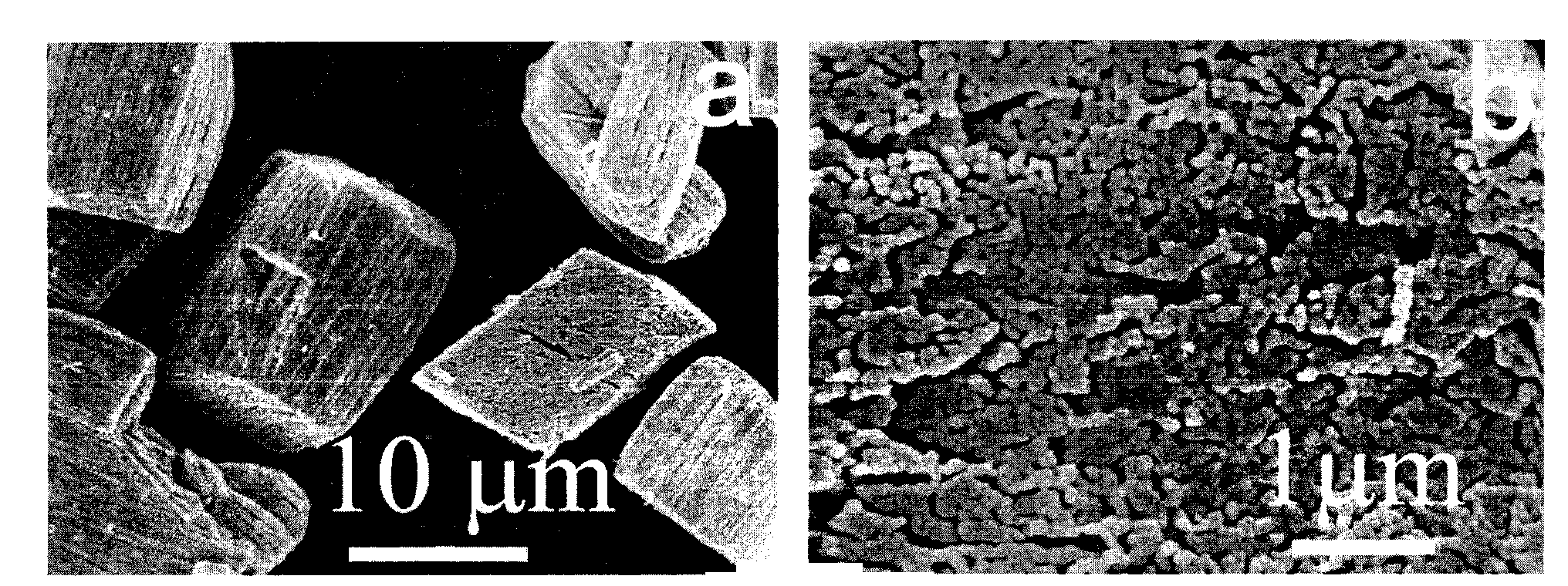

[0029] Step 1, first dropwise add a zinc chloride solution with a concentration of 0.01mol / L to a saturated oxalic acid solution at a temperature of 70°C under stirring; wherein, the rate of dropping is 2ml / min, and a white precipitate is obtained. After washing the white precipitate repeatedly with water and ethanol in sequence, it is dried; wherein, the number of times of repeated washing is more than 3 times, the temperature of the drying treatment is 70 ° C, and the time is 3 hours to obtain the dihydrate zinc oxalate precursor. Next, the precursor of zinc oxalate dihydrate was calcined at 480°C for 2 hours to obtain an approximate figure 1 The porous zinc oxide micron powder shown.

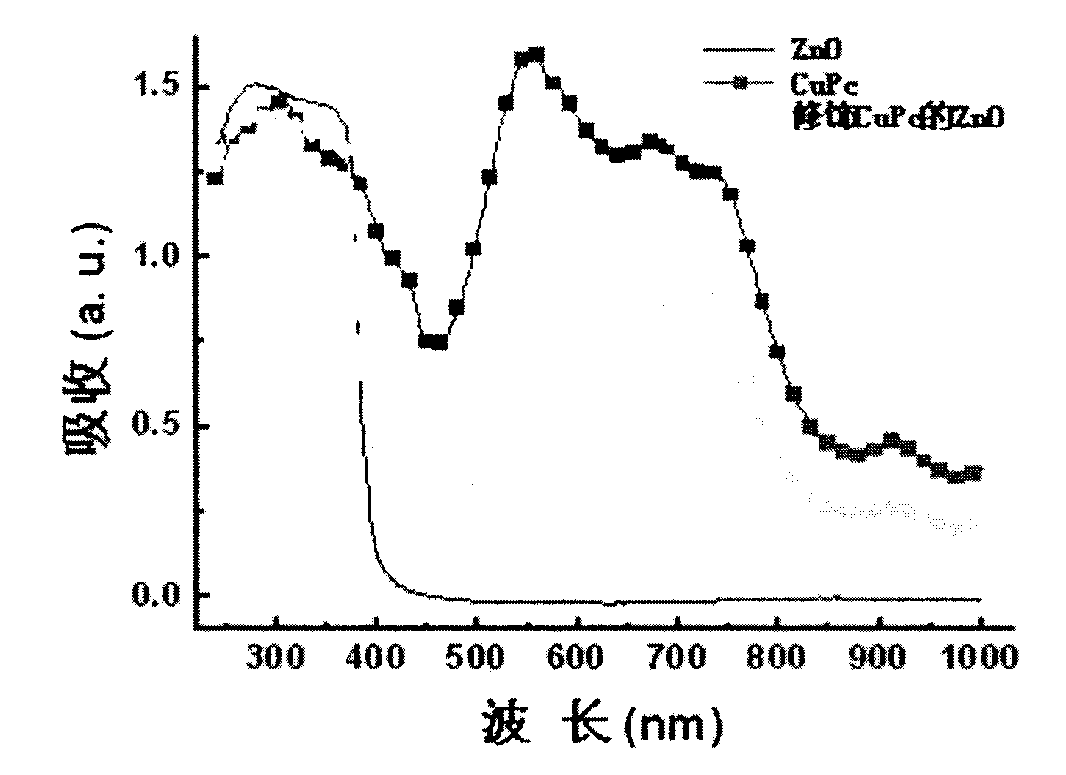

[0030] In step 2, copper phthalocyanine, acetylacetone and ethanol are first mixed according to a molar ratio of 0.002823:0.6738:0.2091 to obtain an impregnation solution. According to the molar ratio between zinc oxide and copper phthalocyanine...

Embodiment 2

[0032] The concrete steps of preparation are:

[0033] In step 1, a zinc chloride solution with a concentration of 0.015 mol / L is added dropwise to a saturated oxalic acid solution at a temperature of 75° C. under stirring; wherein, the rate of dropping is 2 ml / min, and a white precipitate is obtained. After washing the white precipitate repeatedly with water and ethanol in sequence, it is dried; wherein, the number of times of repeated washing is more than 3 times, the temperature during the drying treatment is 75°C, and the time is 2.5h, and the precursor of zinc oxalate dihydrate is obtained. . Next, the precursor of zinc oxalate dihydrate was calcined at 490°C for 1.8 hours to obtain an approximate figure 1 The porous zinc oxide micron powder shown.

[0034] In step 2, copper phthalocyanine, acetylacetone and ethanol are first mixed according to the molar ratio of 0.002824:0.6737:0.2092 to obtain an impregnation solution. Then according to the molar ratio between zinc o...

Embodiment 3

[0036] The concrete steps of preparation are:

[0037] In step 1, a zinc chloride solution with a concentration of 0.02 mol / L is added dropwise to a saturated oxalic acid solution at a temperature of 80° C. under stirring; wherein, the dropping rate is 2 ml / min to obtain a white precipitate. After washing the white precipitate repeatedly with water and ethanol in sequence, it is dried; wherein, the number of times of repeated washing is more than 3 times, the temperature of the drying treatment is 80° C., and the time is 2 hours to obtain the zinc oxalate dihydrate precursor. Next, the dihydrate zinc oxalate precursor was roasted at a temperature of 500°C for 1.5h to obtain the following figure 1 The porous zinc oxide micron powder shown.

[0038] In step 2, copper phthalocyanine, acetylacetone and ethanol are first mixed in a molar ratio of 0.002825:0.6736:0.2093 to obtain an impregnation solution. Then according to the molar ratio between zinc oxide and copper phthalocyani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com