Preparation method of porous graphene

A technology of porous graphene and thin-layer graphene, applied in graphene, chemical instruments and methods, nanotechnology for materials and surface science, etc. , to achieve the effect of high specific surface area, good application prospect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] As mentioned above, in view of the deficiencies in the prior art, the present invention aims to provide a method for preparing porous graphene. As one of the more preferred embodiments, the preparation method may include the following steps:

[0029] 1) preparing intercalated graphite;

[0030] 2) taking a polar solvent to replace the intercalated matter in the intercalated graphite to prepare intercalated graphite containing a large amount of polar solvent;

[0031] 3) Microwave irradiation of intercalated graphite containing polar solvents to prepare porous worm-like expanded graphite;

[0032] 4) Ultrasonic and dry the expanded graphite to prepare porous graphene.

[0033] Obviously, this preparation method can also be extended to prepare other two-dimensional material systems, for example, porous BN, MoS2, WS2, MoSe2, MoTe, TaSe, NbSe, NiTe, Bi2Te materials, etc.

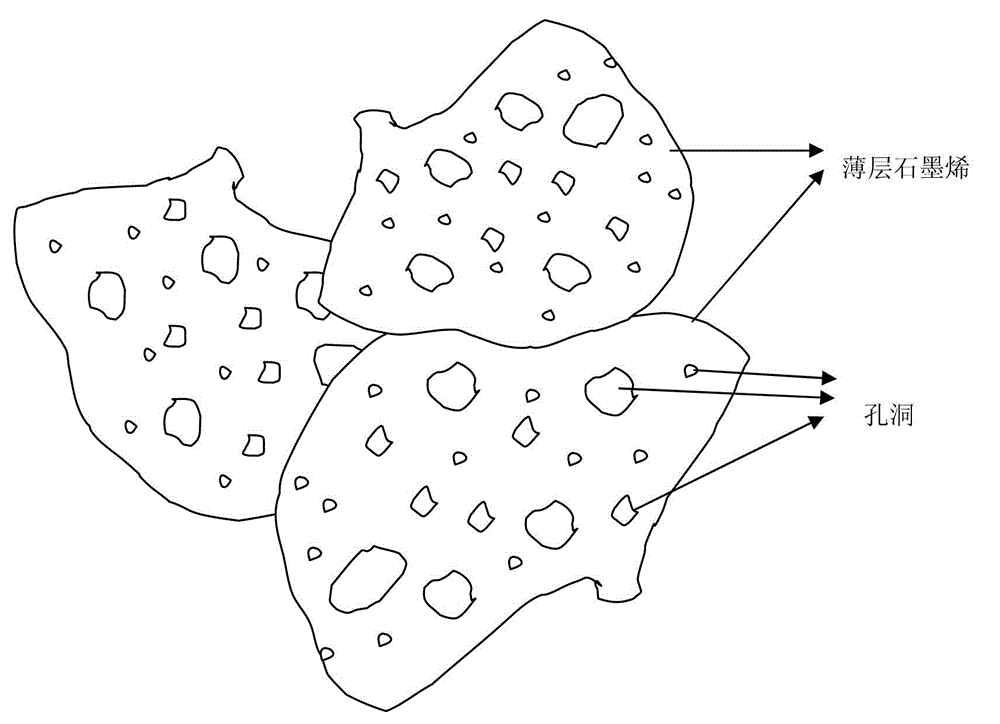

[0034] The aforementioned porous graphene contains a large number of pore structures, the pore size...

Embodiment 1

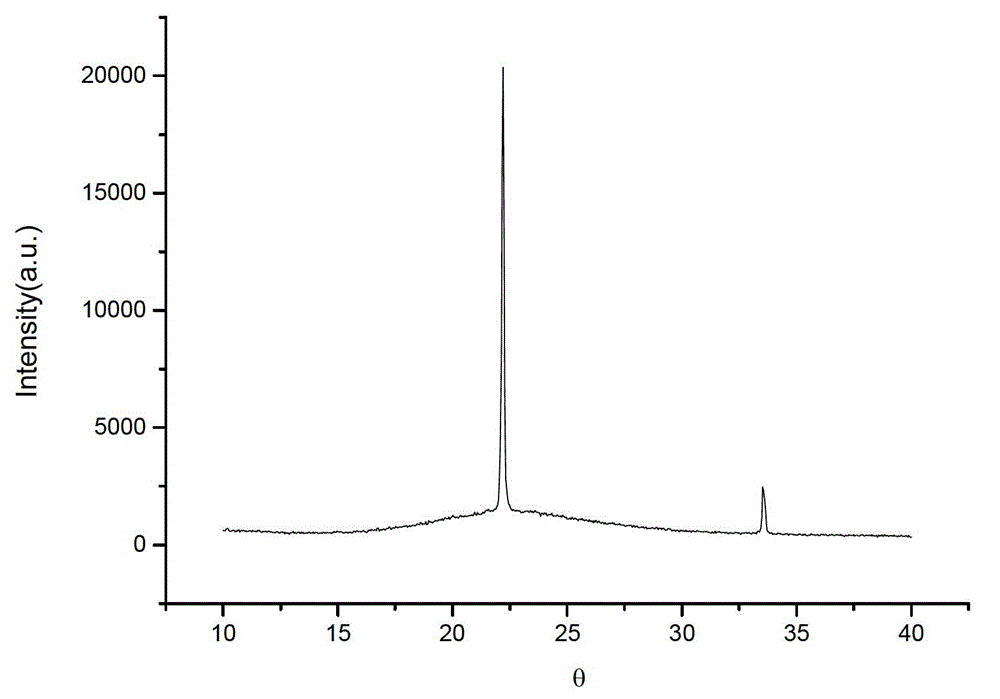

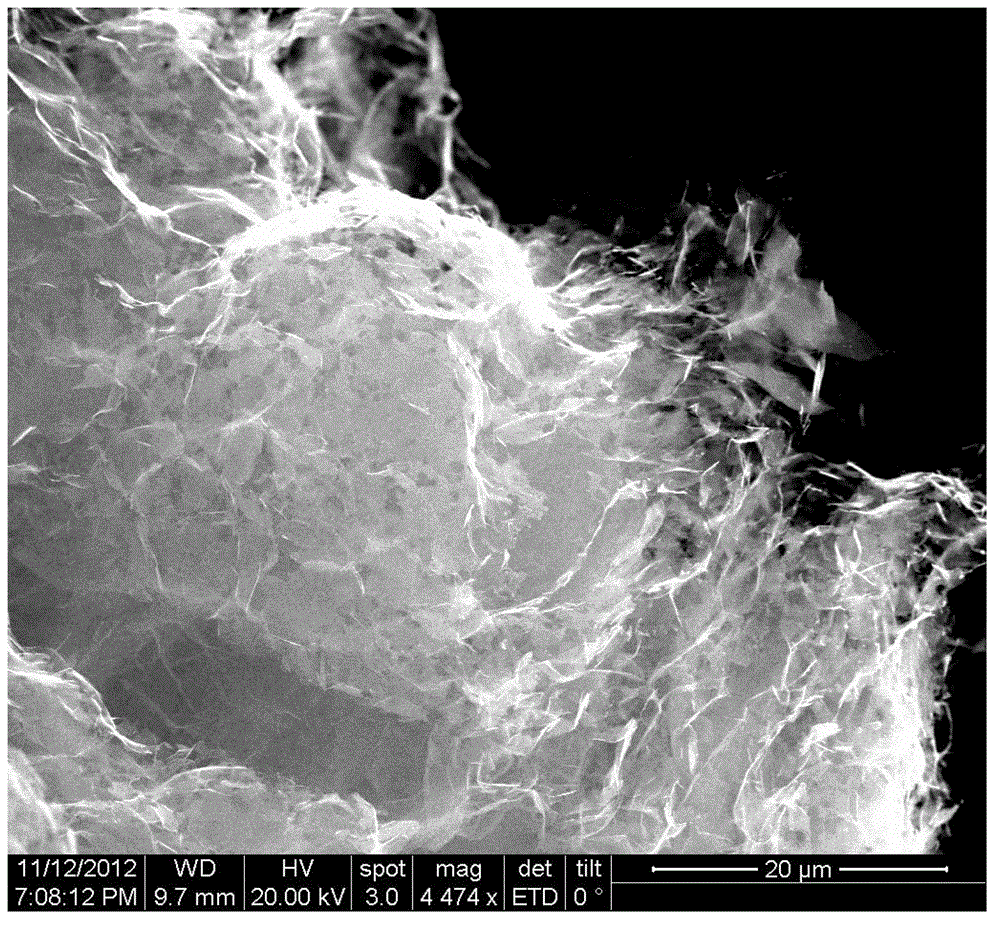

[0043] Embodiment 1: put 10g flake graphite (325 order) in the mixed solution of 20ml concentrated nitric acid and the vitriol oil, fully stir 2 hours, treat that the graphite in the solution becomes dark blue completely, stop stirring, prepare mixed acid intercalation graphite ( Its XRD diagram is shown in figure 1 ), the resulting intercalated graphite was put into a polar solvent, fully stirred and infiltrated for 24 hours, and then dried. Place the dried intercalated graphite in a microwave oven, separate the microwave source from top to bottom, select a microwave power of 5kw, and microwave for 1 minute. Take out the expanded graphite powder, add it to a polar solvent, and ultrasonicate for 2 hours. After being ultrasonically opened, they are dried to obtain porous graphene (see figure 2 and image 3 )

Embodiment 2

[0044] Embodiment 2: 10g flake graphite (325 mesh) and 50g ferric chloride are divided into two zones and put into a glass container, the temperature at one end of graphite is 360°C, and the temperature at one end of ferric chloride is 400°C. After reacting for 24 hours and cooling down, break the glass container, take out the intercalated graphite inside, and wash it. Add ethanol and put it into a ball mill to grind for 10 hours, then take it out and put it into an autoclave containing ethanol, raise the temperature to 120°C, heat for 10 hours, take it out, and dry it. Put the dried intercalated graphite into a microwave oven, separate the microwave source from top to bottom, select the microwave power as 5kw, and microwave time for 30s, take out the expanded graphite powder, add it to water, and ultrasonicate for 2 hours, until all the graphite is ultrasonicated After being opened, it is dried to obtain porous graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com