Mixed liquid fermentation process of three plants of bacillus licheniformis

A technology of Bacillus licheniformis and liquid fermentation, which is applied in the direction of bacteria, mutant preparation, and treatment of microorganisms with electricity/wave energy. Production cost, the effect of optimizing the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

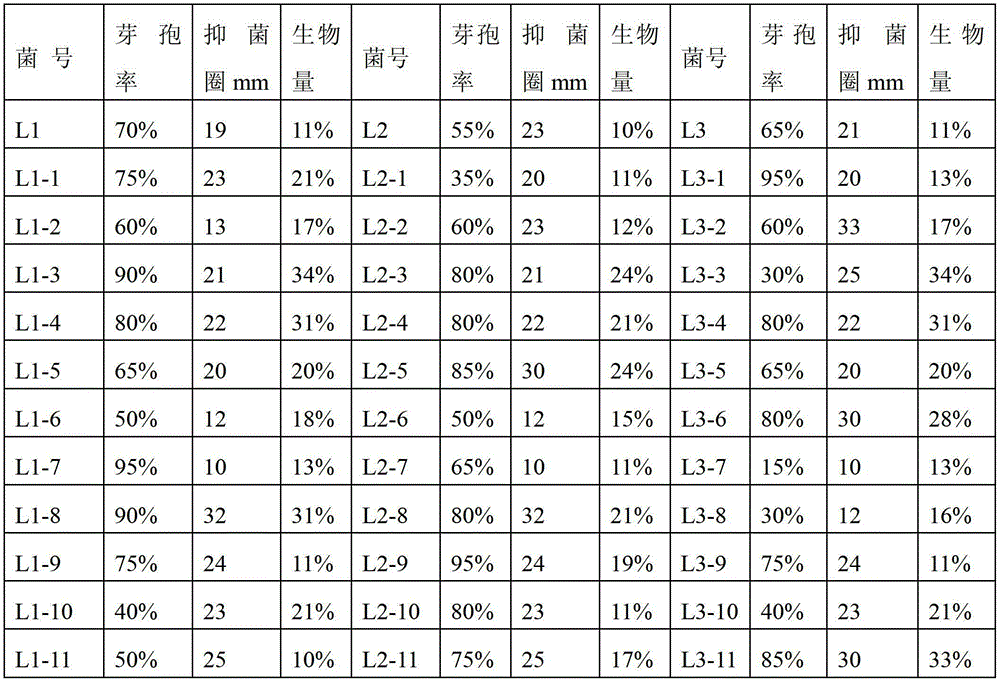

[0025] Example 1 strain screening

[0026] 1. Culture on solid slope

[0027] Three strains of Bacillus licheniformis L1, L2, and L3 were inoculated on the slant medium under aseptic conditions for cultivation, among which: the cultivation condition of Bacillus licheniformis L1 was 37°C for 24 hours, and the cultivation condition of Bacillus licheniformis L2 was 30°C. ℃, 24h, the culture condition of Bacillus licheniformis L3 is 32℃, 24h;

[0028] In terms of weight percentage, the components of the slant medium used are: 0.5% glucose, 0.5% sucrose, 1.0% yeast powder, 0.5% beef extract, 0.5% tryptone, 0.1% diammonium hydrogen phosphate, 0.5% sodium chloride, Manganese sulfate 0.005%, ammonium sulfate 0.5%, dipotassium hydrogen phosphate 0.1%, magnesium sulfate 0.1%, agar 1.5%, the balance is water, and the pH is 7.2.

[0029] 2. Physical and chemical factor mutagenesis

[0030] Take the above-mentioned solid slant culture, and prepare bacterial suspension with 0.9% physiolo...

Embodiment 2-4

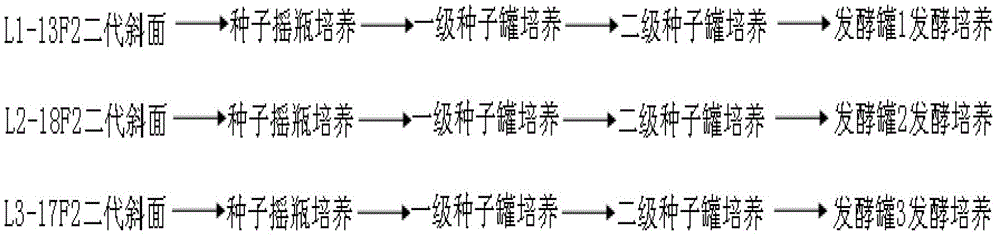

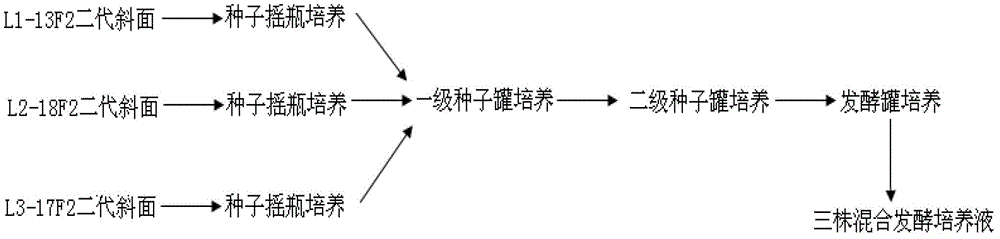

[0055] Embodiment 2-4 mixed fermentation experiment

Embodiment 2

[0057] Under aseptic conditions, take the single colony slant (mother slant) of L1-13, L2-18, and L3-17 out of the refrigerator at 4 °C, wipe the outer wall with 75% alcohol cotton ball, and bring it into the sterile room. On the ultra-clean workbench, use a sterile inoculation shovel to scrape 0.1cm from the mother slope 2 Quickly insert the bacteria lawn into the sterile slant medium, and spread it evenly in an "S" line from top to bottom. After bandaging, culture at 30°C for 48 hours to obtain second-generation seed slopes of L1-13, L2-18, and L3-17, numbered L1-13F2, L2-18F2, and L3-17F2, and store them in a refrigerator at 4°C after the cultivation . In terms of percentage by weight, the components of the slant medium used are: 0.2% glucose, 0.5% sucrose, 0.5% yeast powder, 0.9% beef extract, 0.8% tryptone, 0.1% diammonium hydrogen phosphate, 0.5% sodium chloride, Manganese sulfate 0.005%, ammonium sulfate 0.5%, dipotassium hydrogen phosphate 0.1%, magnesium sulfate 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spore rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com