Manufacturing method of silicon (Si) substrate upper side grid grapheme field effect tube based on copper (Cu) film annealing

A technology for field effect transistors and manufacturing methods, which is applied in the field of microelectronics, can solve the problems of decreased mobility of top-gate graphene field effect transistors, easy damage of graphene films, etc., and achieves low cost, high safety, and avoids scattering effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

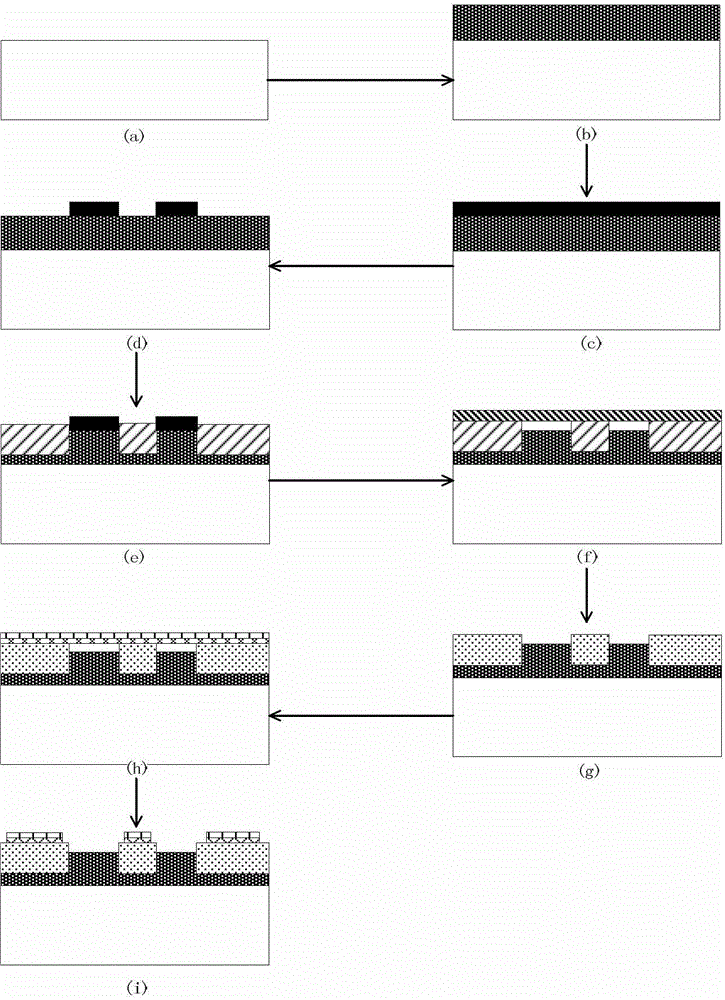

[0033] Step 1: Remove contaminants on the sample surface, such as figure 2 (A).

[0034] Clean the surface of the 4-inch Si substrate substrate, that is, use NH first 4 OH+H 2 O 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the sample surface; then use HCl+H 2 O 2 The reagent is soaked in the sample for 10 minutes, and then dried to remove ionic contaminants.

[0035] Step 2: Growing a carbonized layer.

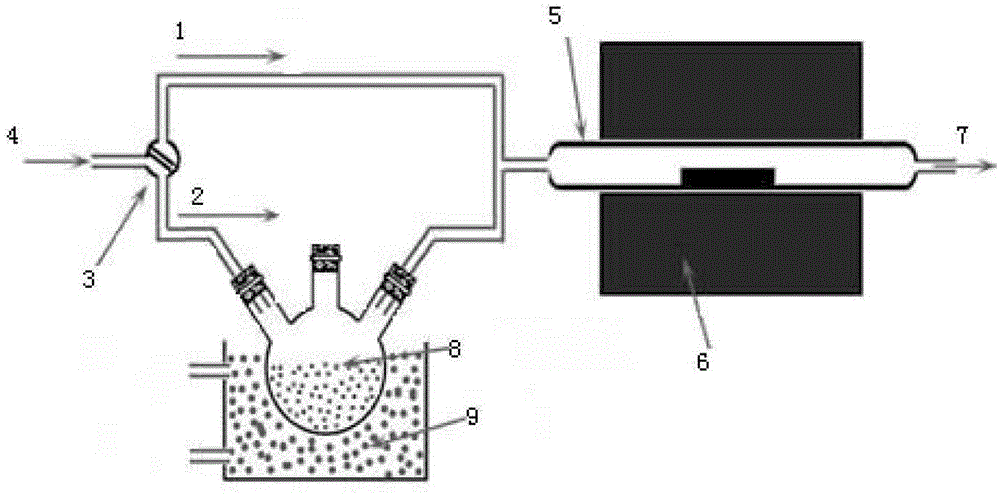

[0036] Put the Si substrate into the reaction chamber of the CVD system, and vacuumize the reaction chamber to 10 -7 mbar level; again at H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 900°C; then the flow rate of C is 40ml / min into the reaction chamber 3 H 8 , Grow a carbonized layer on the Si substrate, the growth time is 8min.

[0037] Step 3: Growing 3C-SiC film on the carbonized layer, such as figure 2 (B).

[0038] The temperature of the reaction cham...

Embodiment 2

[0069] Step 1: Remove contaminants on the sample surface, such as figure 2 (A).

[0070] Perform surface cleaning treatment on the 8-inch Si substrate substrate, that is, use NH first 4 OH+H 2 O 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the sample surface; then use HCl+H 2 O 2 The reagent is soaked in the sample for 10 minutes, and then dried to remove ionic contaminants.

[0071] Step 2: Growing a carbonized layer.

[0072] Put the Si substrate into the reaction chamber of the CVD system, and vacuumize the reaction chamber to 10 -7 mbar level. In H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1100°C, and then C with a flow rate of 40ml / min is passed into the reaction chamber 3 H 8 , Grow a carbonized layer on the Si substrate, the growth time is 3min.

[0073] Step 3: Growing 3C-SiC film on the carbonized layer, such as figure 2 (B).

[0074] The tempe...

Embodiment 3

[0101] Step A: Perform surface cleaning treatment on the 12-inch Si substrate substrate, that is, use NH first 4 OH+H 2 O 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the sample surface; then use HCl+H 2 O 2 The reagent is soaked in the sample for 10 minutes, and then dried to remove ionic contaminants, such as figure 2 (A).

[0102] Step B: Put the Si substrate into the reaction chamber of the CVD system, and vacuum the reaction chamber to 10 -7 mbar level. In H 2 Under protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1000°C, and then a flow rate of 40ml / min of C is introduced into the reaction chamber 3 H 8 , Grow a carbonized layer on the Si substrate, the growth time is 5min.

[0103] Step C: Raise the temperature of the reaction chamber rapidly to the growth temperature of 1200℃, and pass in SiH with flow rates of 25ml / min and 50ml / min respectively 4 And C 3 H 8 , Perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com