Porous light-weight carbon-based biological carrier and preparation method thereof

A biological carrier and lightweight technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large reactor fluidization power consumption, microbial film formation and microbial biomass Poor, complex processing technology and other issues, to achieve the effect of improving adsorption capacity and film-hanging amount, easy quantity, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

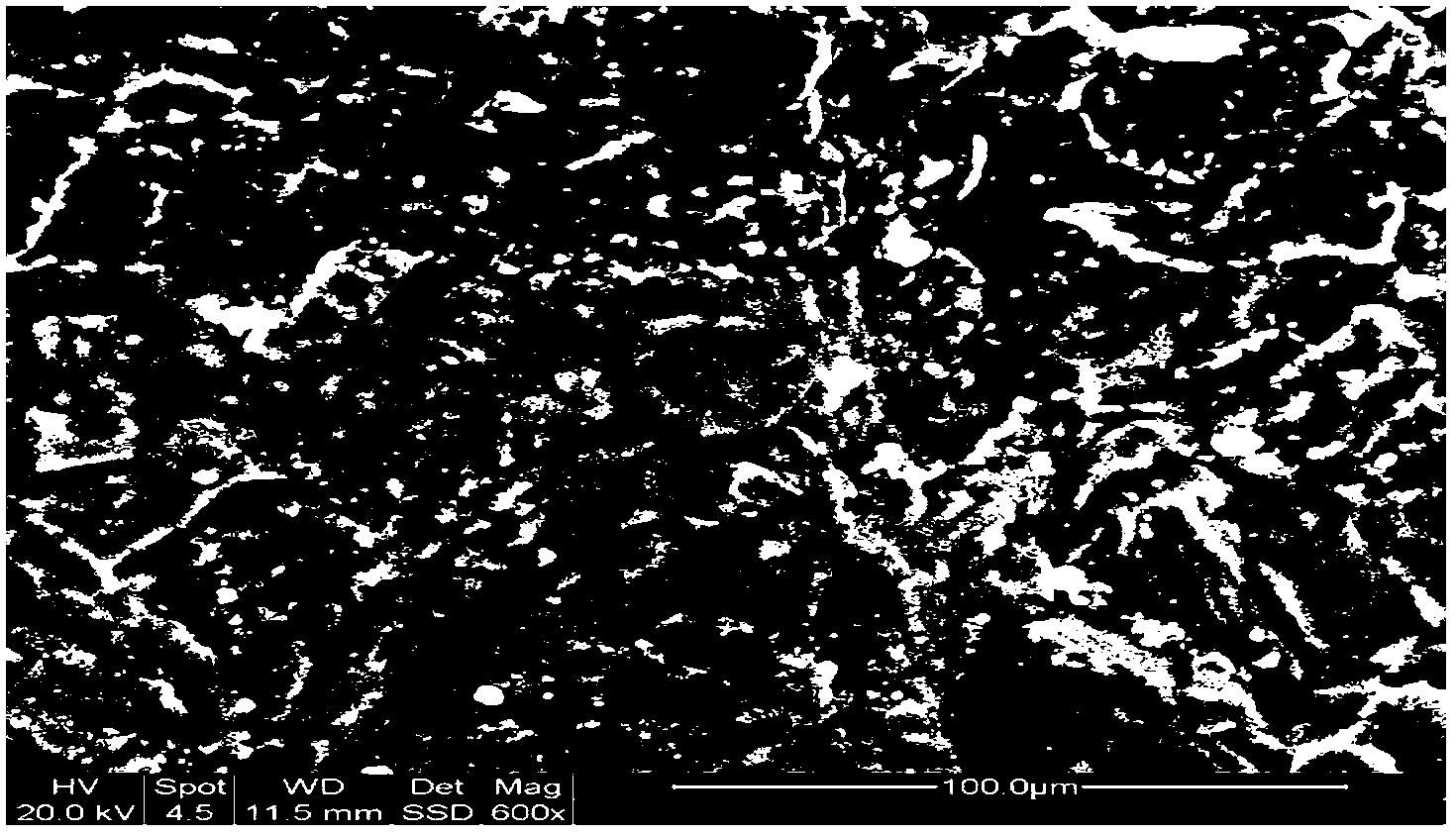

Image

Examples

Embodiment 1

[0023] A porous light carbon-based biological carrier, which is prepared according to the following steps:

[0024] 1) First, dissolve 15g of polyvinyl alcohol with a degree of polymerization of 1750 in 85ml of boiling water at 100°C and stir for 8 hours under reflux to obtain a 15% by weight polyvinyl alcohol solution;

[0025] 2) Next, take coke powder with a particle size of 300 mesh and put it in a nitric acid solution with a concentration of 50% by weight at room temperature for oxidation modification, treat it for 2 hours, take it out and wash it to neutral, and then wash it with tap water for 3 times;

[0026] 3) Then dry the coke powder in an oven at a constant temperature of 100°C for 2 hours;

[0027] 4), then add 5g of coke powder, 5ml of sodium lauryl sulfate aqueous solution with a concentration of 0.5% by weight and 2ml of an aqueous solution of glutaraldehyde with a concentration of 0.5% by weight to the 100ml of polyvinyl alcohol solution in step 1) Stir rapid...

Embodiment 2

[0033] A porous light carbon-based biological carrier, which is prepared according to the following steps:

[0034] 1) First, dissolve 10g of polyvinyl alcohol with a degree of polymerization of 1850 in 90ml of boiling water at 100°C and stir for 8 hours under reflux to obtain a 10% by weight polyvinyl alcohol solution;

[0035] 2) Next, take coke powder with a particle size of 180 mesh and put it in a nitric acid solution with a concentration of 30% by weight at room temperature for oxidative modification, treat it for 3 hours, take it out and wash it to neutral, and then wash it with tap water 4 times;

[0036] 3) Then dry the coke powder in an oven at a constant temperature of 90°C for 1.5h;

[0037] 4) Add 10g of coke powder, 5ml of sodium lauryl sulfate aqueous solution with a concentration of 1.0% by weight and 2ml of an aqueous solution of glutaraldehyde with a concentration of 1.0% by weight to the 100ml of polyvinyl alcohol solution in step 1) Stir rapidly for 3 hour...

Embodiment 3

[0043] A porous light carbon-based biological carrier, which is prepared according to the following steps:

[0044] 1) First, dissolve 5g of polyvinyl alcohol with a degree of polymerization of 1900 in 95ml of boiling water at 100°C and stir for 8 hours under reflux to obtain a 5% by weight polyvinyl alcohol solution;

[0045] 2) Next, take coke powder with a particle size of 200 mesh and put it in a nitric acid solution with a concentration of 10% by weight at room temperature for oxidation modification, treat it for 5 hours, take it out and wash it to neutral, and then wash it with tap water for 3 times;

[0046] 3), and then dry the coke powder in an oven at a constant temperature of 90°C for 2 hours;

[0047] 4), then add 5g of coke powder, 5ml of sodium lauryl sulfate aqueous solution with a concentration of 2.0% by weight and 2ml of an aqueous solution of glutaraldehyde with a concentration of 1.5% by weight to the 100ml of polyvinyl alcohol solution in step 1) Stir rap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com